Tray capable of eliminating warping of wafers

A wafer and warpage technology, applied in the field of trays to eliminate wafer warpage, can solve the problems of reducing yield and stability, generating stress, affecting component uniformity, etc., and maintaining the temperature field and flow field. Stable and reliable, eliminating the effects of different thermal expansion coefficients and lattice constants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

[0021] The tray capable of eliminating warpage of wafers described in this embodiment is made of high-temperature-resistant materials, usually high-purity graphite or silicon carbide, and can be coated with coatings such as silicon carbide and tantalum carbide as required.

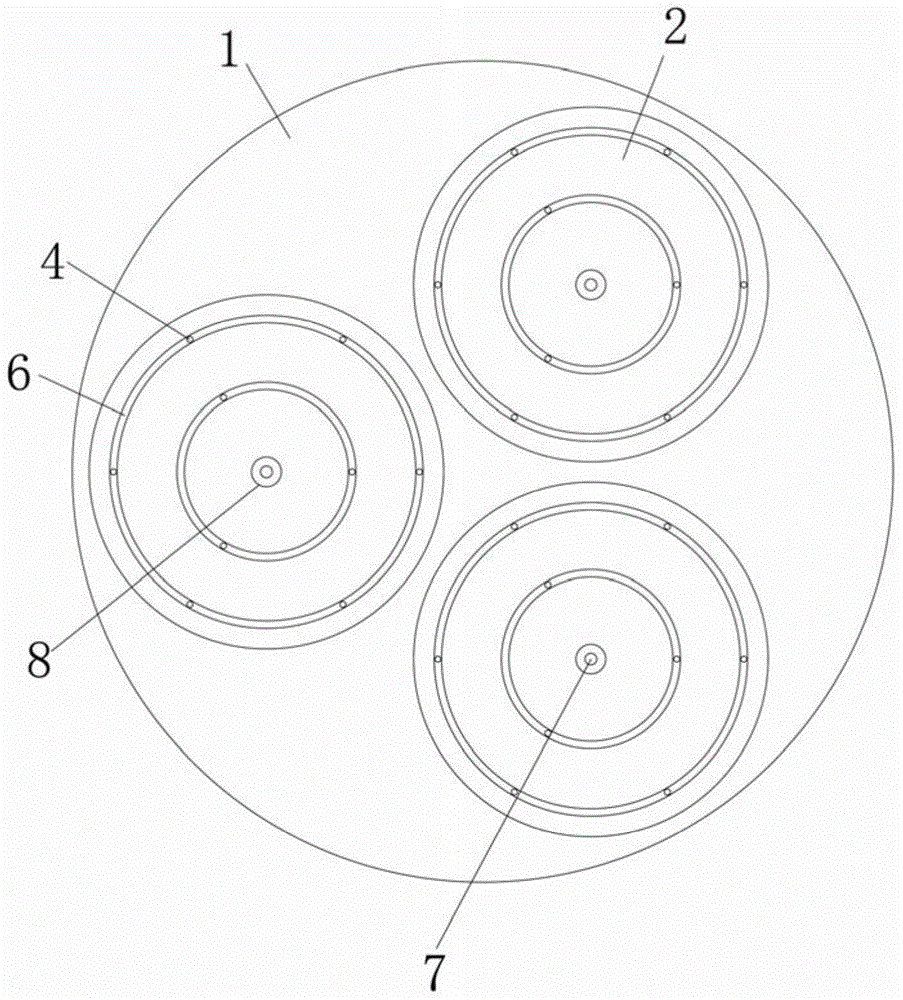

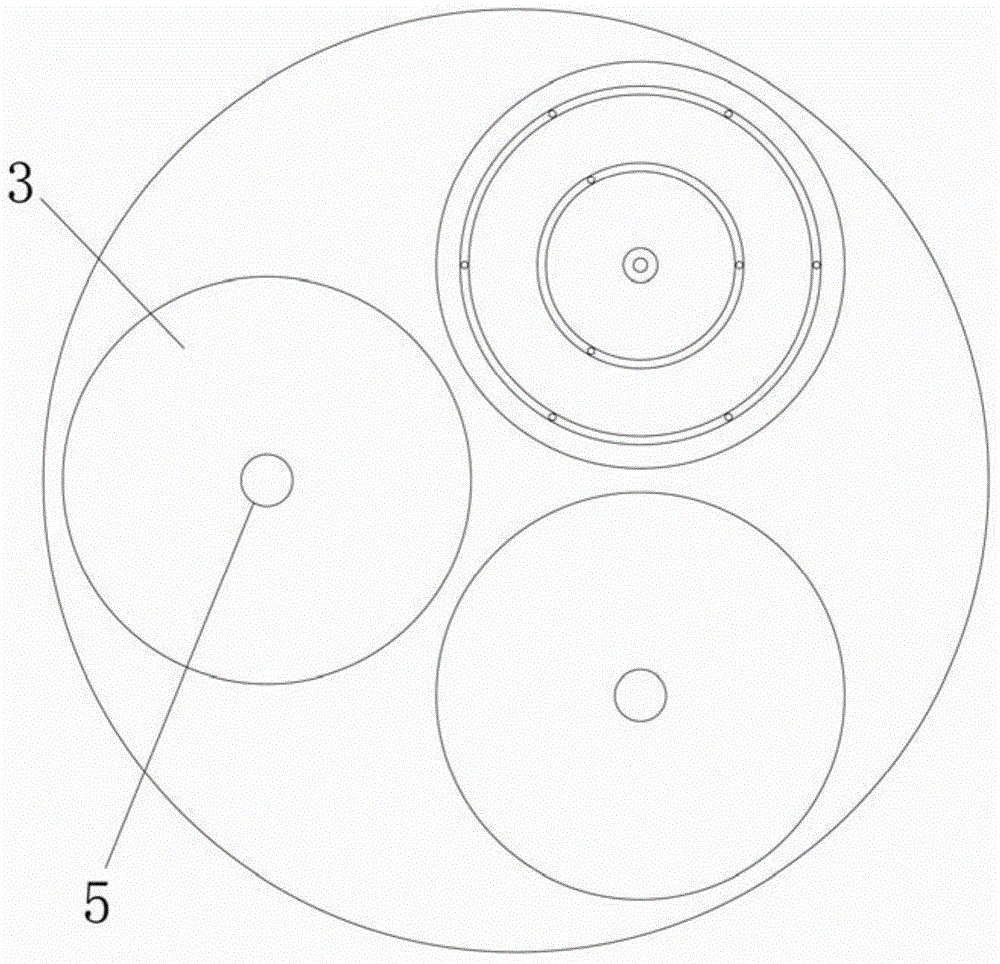

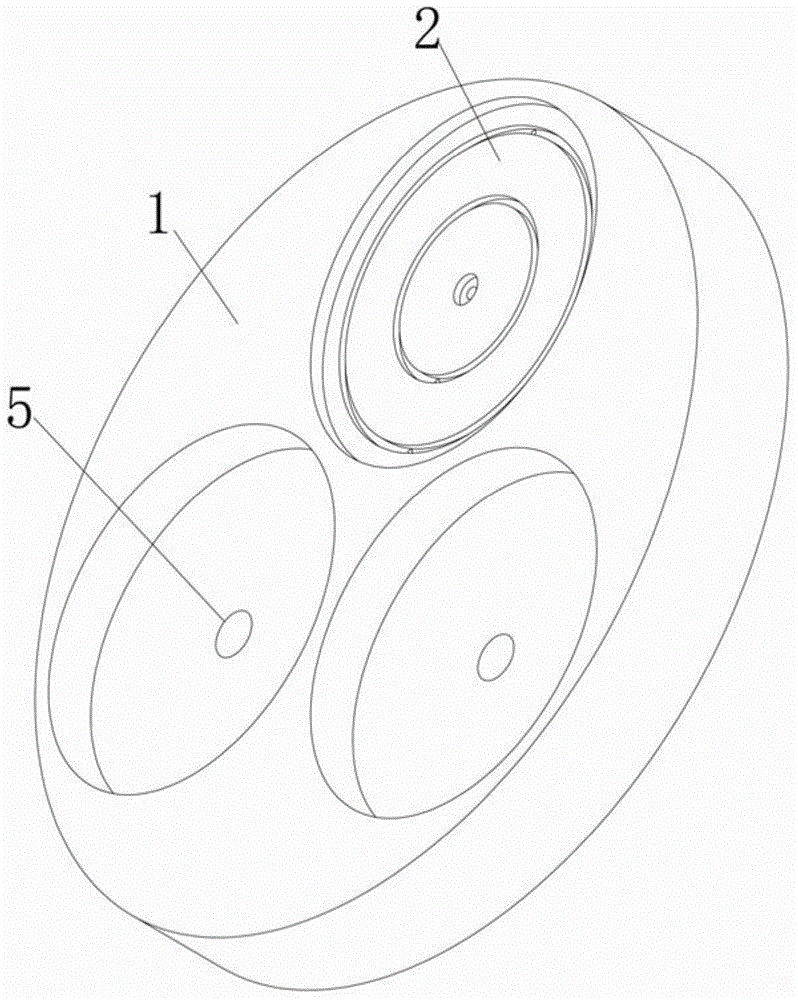

[0022] Such as Figure 1 to Figure 4 As shown, the tray includes a circular base 1 (the shape of the base can be selected from other shapes, such as square, polygon, etc.) and a circular base 2 for mounting wafers, wherein the There are three circular pits 3 formed on one side of the substrate 1, the number of the pits 3 is consistent with the base 2, and one pit 3 is equipped with a base 2, the shape and size of the base 2 is the same as that of the pit 3 matches. The base 2 is embedded in the corresponding pit 3, and there is a gap between the base 2 and the bottom of the pit for air to flow through wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com