A surface treatment method for high-purity metal sputtering target

A metal sputtering and surface treatment technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as easy corrosion, high risk, and difficult operation, and achieve stress and dislocation elimination, low material loss, and universal sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

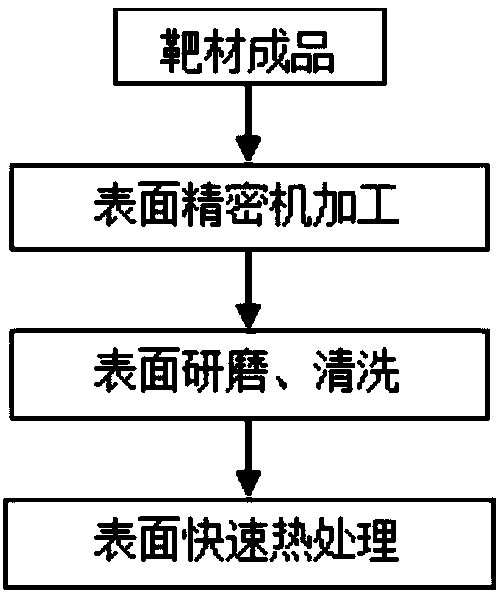

Method used

Image

Examples

Embodiment 1

[0030] (1) Use a diamond knife with higher hardness to precisely machine the surface of the cobalt target, control the finishing feed and machining speed, the feed amount is controlled below 0.5mm, the machining speed of the machine tool is controlled at 200 rpm, and the surface after machining Roughness≤0.8μm;

[0031] (2) The surface of the target material obtained in step (1) is ground with a wire drawing cloth, so that the surface of the target material forms diffuse emission and reduces the surface reflectance; cleans the surface of the target material to prevent surface contamination from affecting the heat treatment quality;

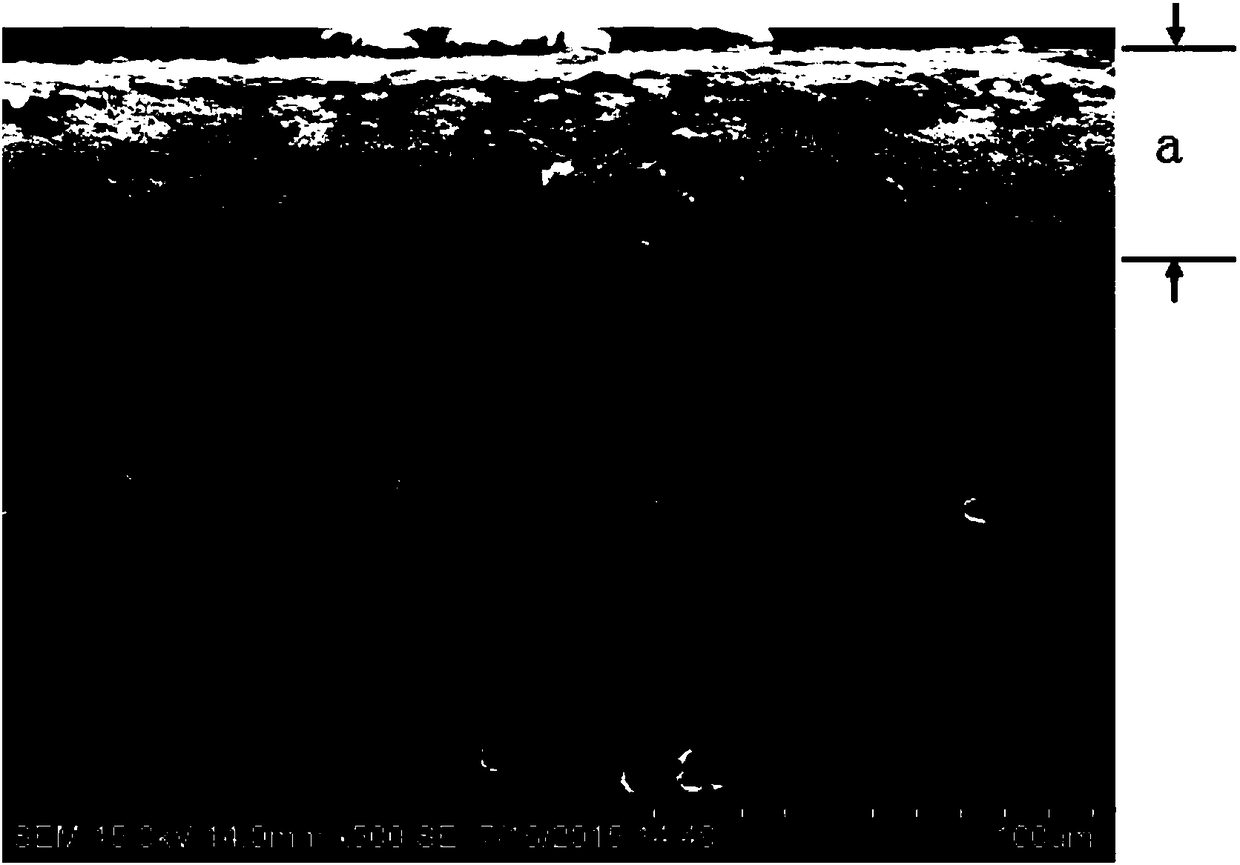

[0032] (3) Under vacuum conditions, the carbon dioxide laser machine uses the lap reciprocating scanning method to scan the surface of the target material obtained in step (2). The power of the laser machine is 2kW, and the target material is inclined 15° during the scanning process to prevent the beam reflected from the surface from burning the la...

Embodiment 2

[0036] Steps (1) and (2) are with embodiment 1;

[0037] (3) Under vacuum conditions, the electron beam is used to scan the sputtering surface of the metal target, and the power density of the electron beam spot is controlled at 2kW / cm when the surface is heated. 2 , the heating rate is 100°C / s, the temperature is heated to 420°C, and the holding time is 10s, so that the metal surface is heated to above the recrystallization temperature. During the scanning process, the spiral scanning method is adopted, the scanning speed is 40mm / s, and a target material with a diameter of Φ440mm is used, and the scanning process takes about 5 minutes. Rapid recrystallization occurs on the surface of the target material, eliminating the work hardening layer on the surface of the material.

Embodiment 3

[0039] Steps (1) and (2) are with embodiment 1;

[0040] (3) Under vacuum conditions, halogen lamps are used to rapidly heat the sputtering surface of the metal target. The heating method is the overall irradiation of the target surface. The heat treatment time is affected by the irradiation range of the halogen lamp. It takes about 3 minutes to irradiate a target with a diameter of Φ440mm. Recrystallization occurs on the surface of the target material to eliminate the work hardening layer on the surface of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com