A deformation heat treatment method for improving the tensile properties of 6000 series aluminum alloy sheet

A technology for deformation heat treatment and tensile properties, applied in the field of improving the tensile properties of 6000 series aluminum alloy sheets, can solve the problems of high equipment requirements, reduced alloy plasticity, complicated procedures, etc., and achieves elimination of dislocation, good plasticity, and maintenance of plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

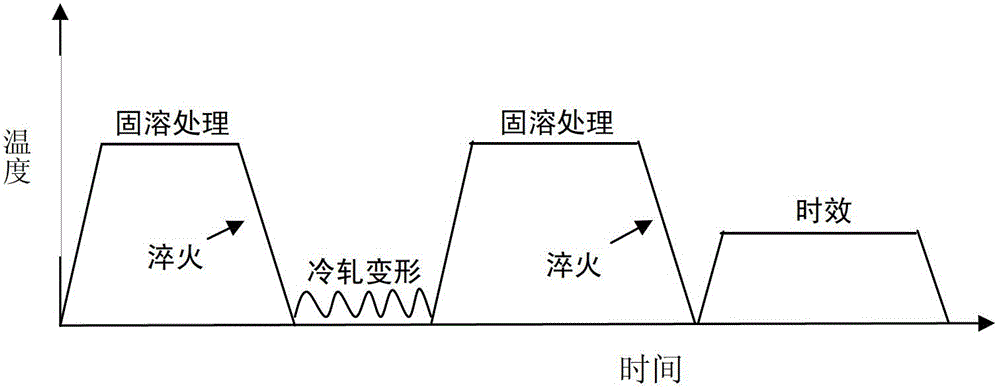

Method used

Image

Examples

Embodiment 1

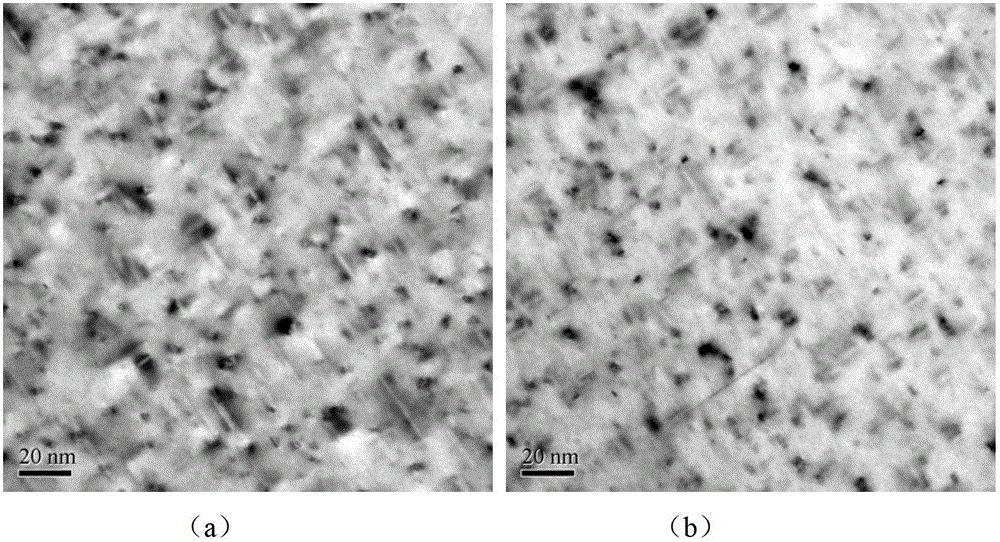

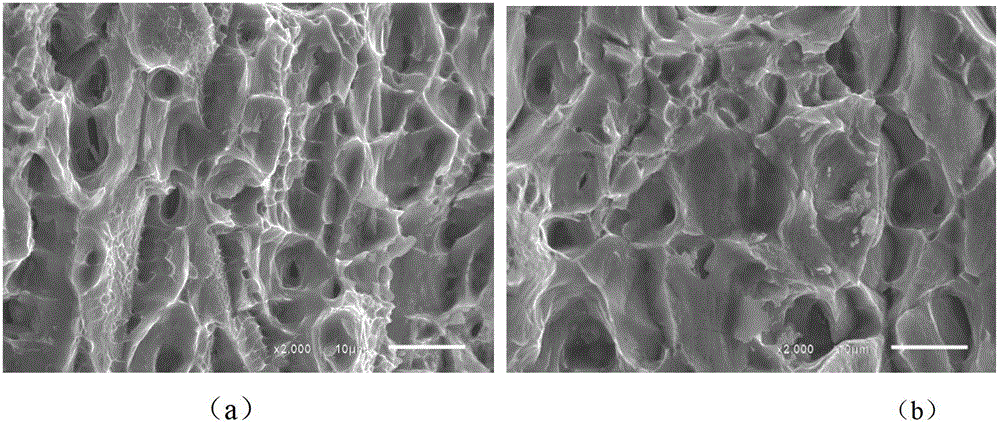

[0029] 6061 aluminum alloy hot-rolled plate, after 550 ℃ / 1h solution treatment and water quenching, the cold rolling deformation is 75%. After that, after solution treatment at 550°C / 1h and water quenching, peak aging at 180°C / 6h. At this time, the tensile properties of the alloy are shown in Table 1, and the precipitation phase of the matrix is shown in Table 1. figure 2 b, tensile fracture morphology see image 3 b.

[0030] From figure 2 It can be seen that the precipitated phases of the matrix in the alloy T6 state treated by the two processes of Comparative Example 1 and Example 1 are mainly β″ phase and a very small amount of Q′, indicating that the treatment of the present invention does not affect the aging precipitation behavior of 6061 alloy, that is, It is said that it does not affect its aging strengthening effect.

[0031] From image 3 It can be seen that the tensile fractures of the alloy T6 treated by the processes of Comparative Example 1 and Exampl...

Embodiment 2

[0034] 6061 aluminum alloy hot-rolled sheet, after 560°C / 1h solution treatment and water quenching, the cold rolling deformation is 60%; after that, after 560°C / 1h solution treatment and water quenching, 170°C / 10h peak aging. At this time, the tensile properties of the alloy are shown in Table 1.

Embodiment 3

[0036] 6061 aluminum alloy hot-rolled sheet, after 530℃ / 1h solution treatment and water quenching, the cold rolling deformation is 80%; after that, after 530℃ / 1h solution treatment and water quenching, 160℃ / 18h peak aging . At this time, the tensile properties of the alloy are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com