Flash memory and manufacturing method therefor

A manufacturing method and technology of flash memory, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of unfavorable gate coupling rate and unfavorable component erasing operation, so as to improve memory data retention and eliminate memory cell dislocations , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

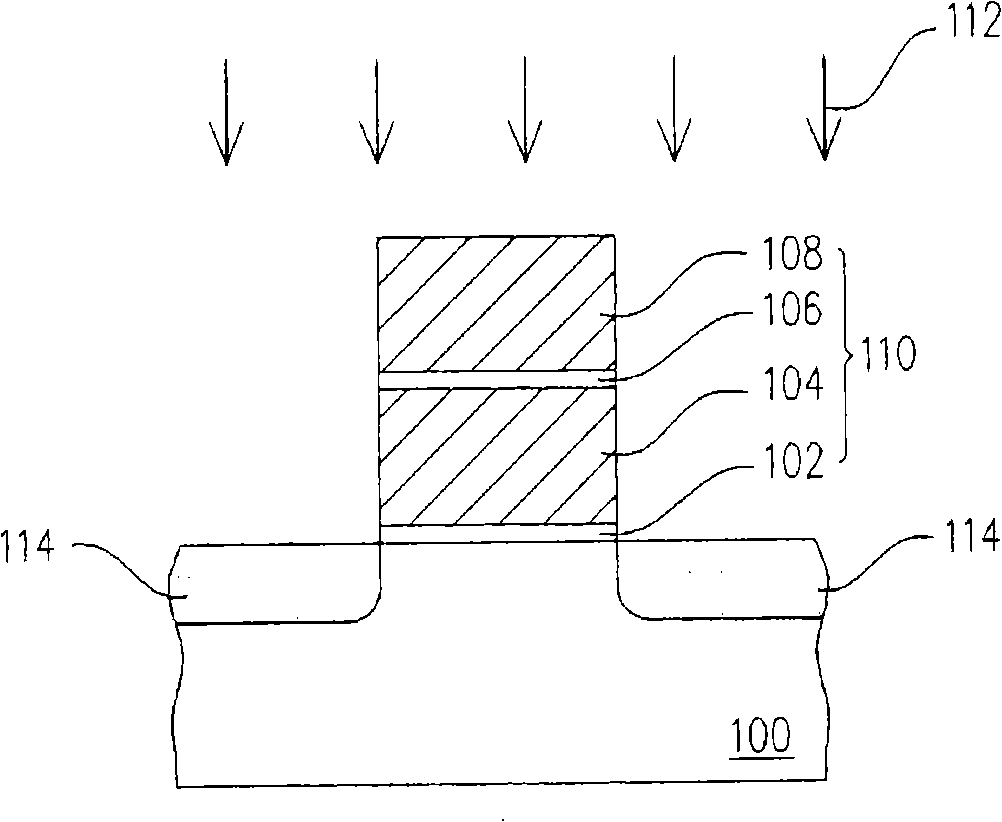

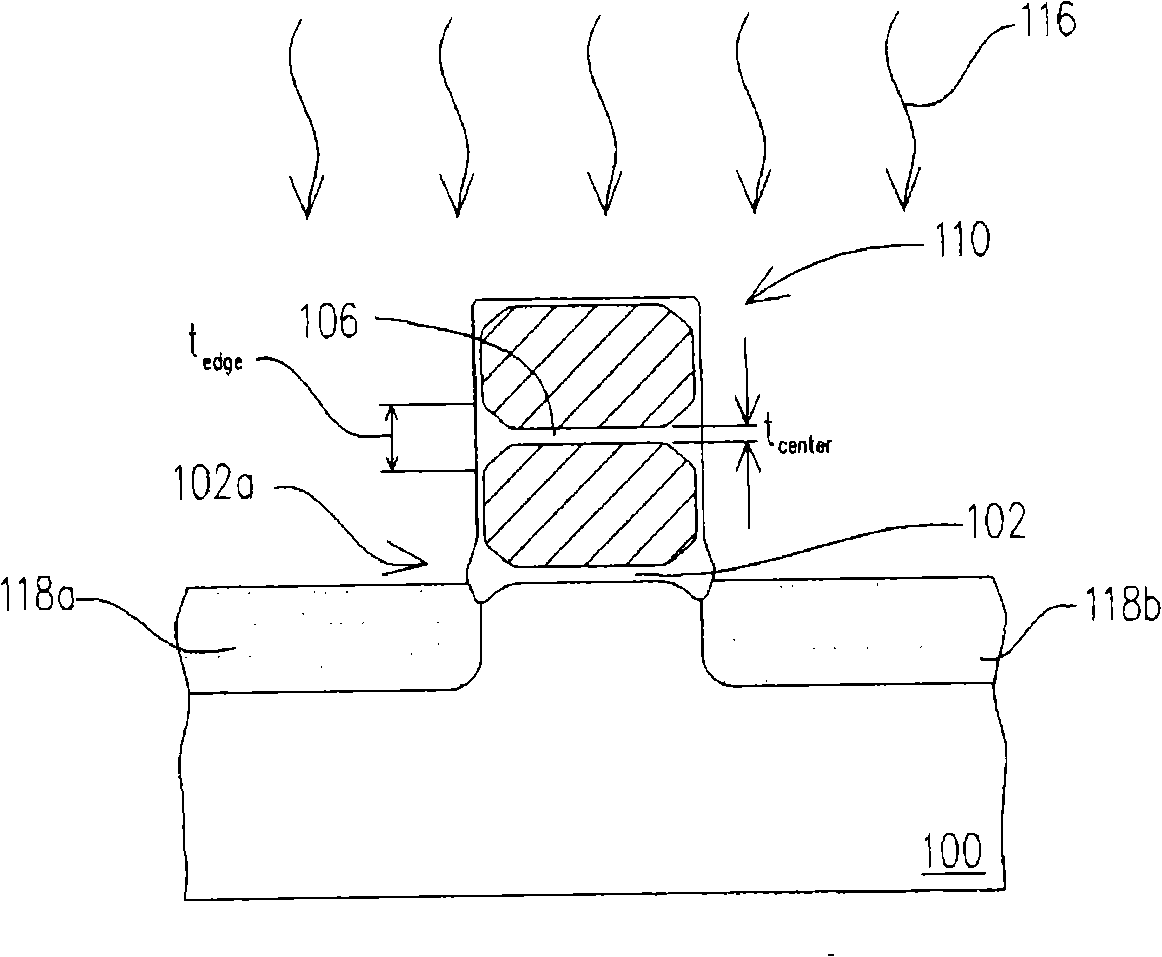

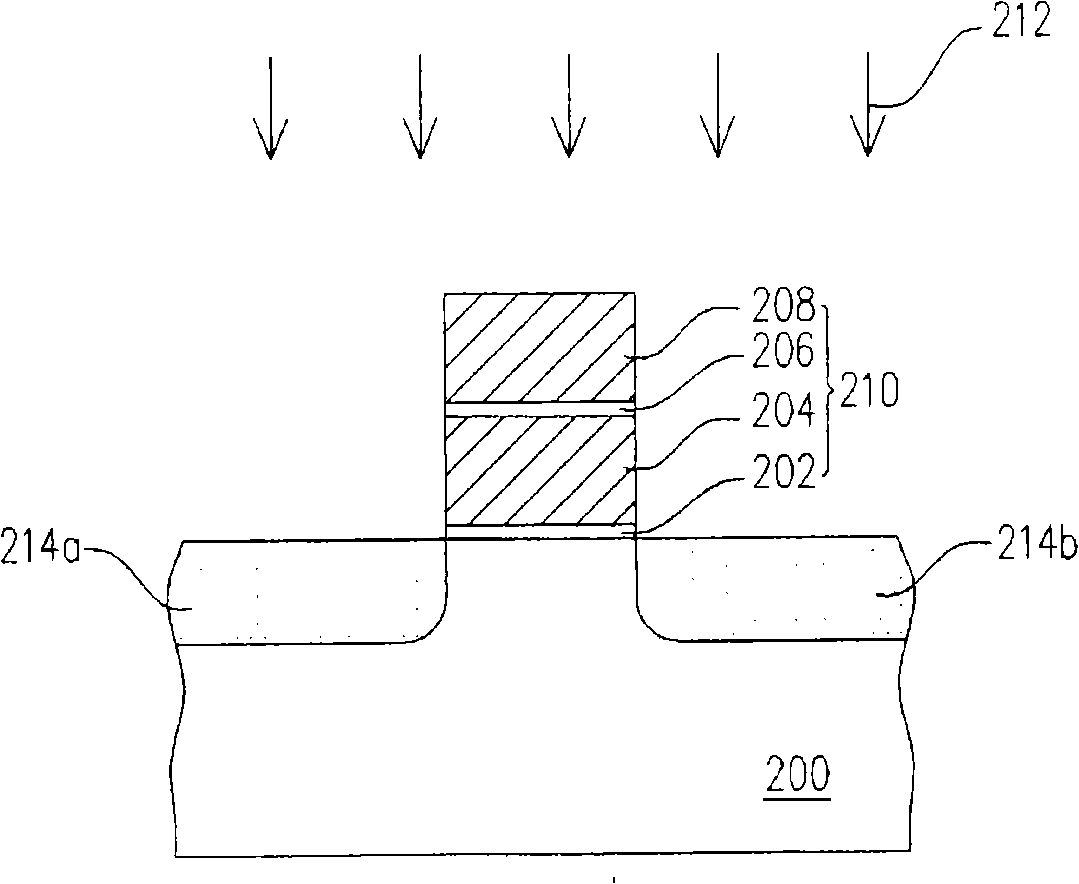

[0051] 2A to 2EIt is a cross-sectional view of a manufacturing process of a flash memory according to an embodiment of the present invention.

[0052] Please refer to Figure 2A , a stack structure 210 is formed on the substrate 200. The stack structure 210 includes, for example, a tunnel oxide layer 202, a charge storage layer 204, an inter-gate dielectric layer 206 and an inter-gate dielectric layer 206 sequentially from the substrate 200. Control gate 208 . The material of the charge storage layer 204 is, for example, doped polysilicon, silicon nitride or other materials that can store charges. The tunnel oxide layer 202 and the inter-gate dielectric layer 206 are, for example, one of materials selected from the group consisting of oxide layers, nitride layers, nitride and oxide layers, oxides and nitrides and oxide layers. The material of the control gate 208 is, for example, one of materials including doped polysilicon, metal silicide, and conductive metal. In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com