Multi-element alloy brazing filler metal for vacuum sealing

A multi-element alloy and alloy solder technology, which is applied in welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of difficulty in meeting the requirements of lower melting point solder, increased alloy brittleness, poor processing performance, etc. Achieve the effect of eliminating residual stress, optimizing lattice arrangement, and improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

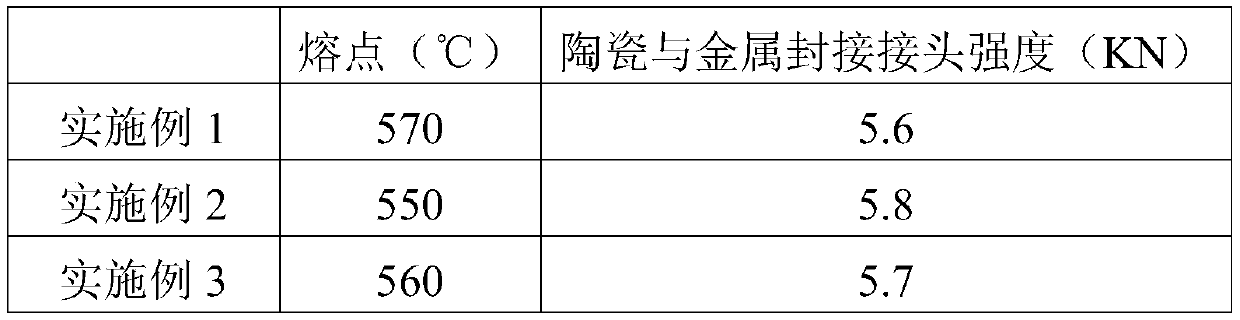

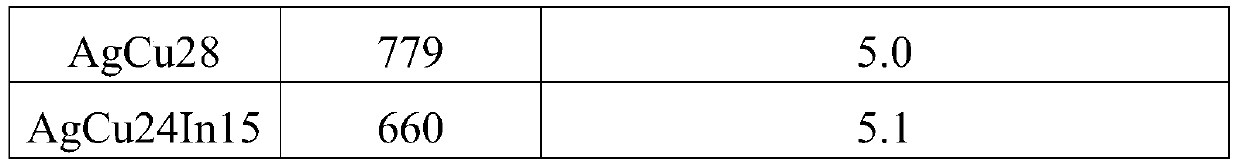

Embodiment 1

[0022] A multi-element alloy brazing filler metal for vacuum sealing, the composition of each metal element is shown in Table 1, and the preparation method thereof comprises the following steps:

[0023] (1) Put the raw materials Ag, Cu, In, Ge, Ga, Y, Ce into the vacuum melting furnace according to the proportion. After the vacuum degree in the furnace is pumped to 0.02Pa, the furnace is heated to 1500 ° C and filled with nitrogen protective gas. , keep the temperature for 40min, and then reduce the temperature to 900℃, cast the alloy liquid into the graphite crucible shaping mold;

[0024] (2) vacuum annealing the cast ingot, the annealing temperature is 500 ℃, the temperature is kept for 1.5h, and the ingot is naturally cooled to room temperature to take out the ingot;

[0025] (3) The ingot after the annealing treatment in step (2) is subjected to pickling treatment, and the pickling solution is a mixed solution of 10% sulfuric acid and 12% chromic anhydride.

[0026] (4)...

Embodiment 2

[0031] A multi-element alloy brazing filler metal for vacuum sealing, the composition of each metal element is shown in Table 1, and the preparation method thereof comprises the following steps:

[0032] (1) Put the raw materials Ag, Cu, In, Ge, Ga, Y, Ce into the vacuum melting furnace according to the proportion. After the vacuum degree in the furnace is pumped to 0.1Pa, the furnace is heated to 1550 ° C and filled with nitrogen protective gas , keep the temperature for 35min, and then reduce the temperature to 950℃, cast the alloy liquid into the graphite crucible mold;

[0033] (2) vacuum annealing the cast ingot, the annealing temperature is 520 ℃, keep for 1h, and naturally cool to room temperature to take out the ingot;

[0034] (3) The ingot after the annealing treatment in step (2) is subjected to pickling treatment, and the pickling solution is a mixed solution of 12% sulfuric acid and 13% chromic anhydride.

[0035] (4) hot-rolling the ingot processed in step (3), ...

Embodiment 3

[0040] A multi-element alloy brazing filler metal for vacuum sealing, the composition of each metal element is shown in Table 1, and the preparation method thereof comprises the following steps:

[0041] (1) Put the raw materials Ag, Cu, In, Ge, Ga, Y, Ce into the vacuum melting furnace according to the proportion. After the vacuum degree in the furnace is pumped to 0.4Pa, the furnace is heated to 1600 ° C and filled with nitrogen protective gas. , keep the temperature for 30min, and then reduce the temperature to 1000℃, cast the alloy liquid into the graphite crucible mold;

[0042] (2) vacuum annealing the cast ingot, the annealing temperature is 550°C, the temperature is kept for 0.5h, and the ingot is naturally cooled to room temperature to take out the ingot;

[0043] (3) The ingot after the annealing treatment in step (2) is subjected to pickling treatment, and the pickling solution is a mixed solution of 13% sulfuric acid and 14% chromic anhydride.

[0044] (4) hot-rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com