Low resistivity high thermal-stability copper-nickel-molybdenum alloy film and producing method thereof

一种高热稳定性、合金薄膜的技术,应用在金属材料涂层工艺、真空蒸发镀覆、涂层等方向,能够解决难以确定掺杂原子添加量、薄膜电阻率不能降低、增加电子散射等问题,达到消除电子散射效应、低电阻率、减低电子散射的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

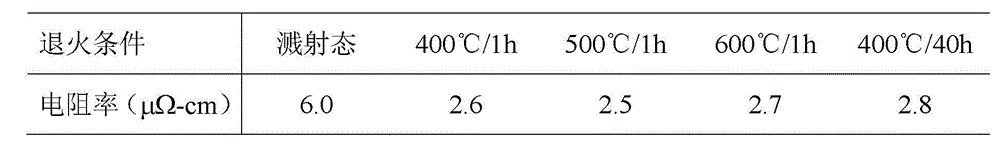

Image

Examples

Embodiment 1

[0029] The following composition is Cu 99.73 Ni 0.25 Mo 0.02 (atomic percent) [Cu 99.74 Ni 0.23 Mo 0.03 (weight percent)] as an example to describe the preparation process steps:

[0030] The first step is to prepare the composite alloy target. Material preparation: According to the Ni and Mo components in the design composition, weigh the value of each component and wait for use. The purity of Ni and Mo metal raw materials is required to be more than 99%; smelting of Ni-Mo alloy ingots: put the metal mixture In the water-cooled copper crucible of the arc melting furnace, the non-consumable arc melting method is used for melting under the protection of argon, and the vacuum is firstly pumped to 10 -2 Pa, then filled with argon until the pressure is 0.03±0.01MPa, the control range of melting current density is 150±10A / cm 2 , after melting, continue to smelt for 10 seconds, turn off the power, let the alloy cool down to room temperature with the copper crucible, then turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com