Nickel-titanium alloy preparation method for improving radial stability and medical device

A nickel-titanium alloy and stability technology, which is applied in the preparation method of nickel-titanium alloy and the field of medical devices, can solve the problems of uneven microscopic defects of the stent structure, and the effect of improving the cycle stability is not obvious, so as to achieve improved cycle stability and low cost , Improve the effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

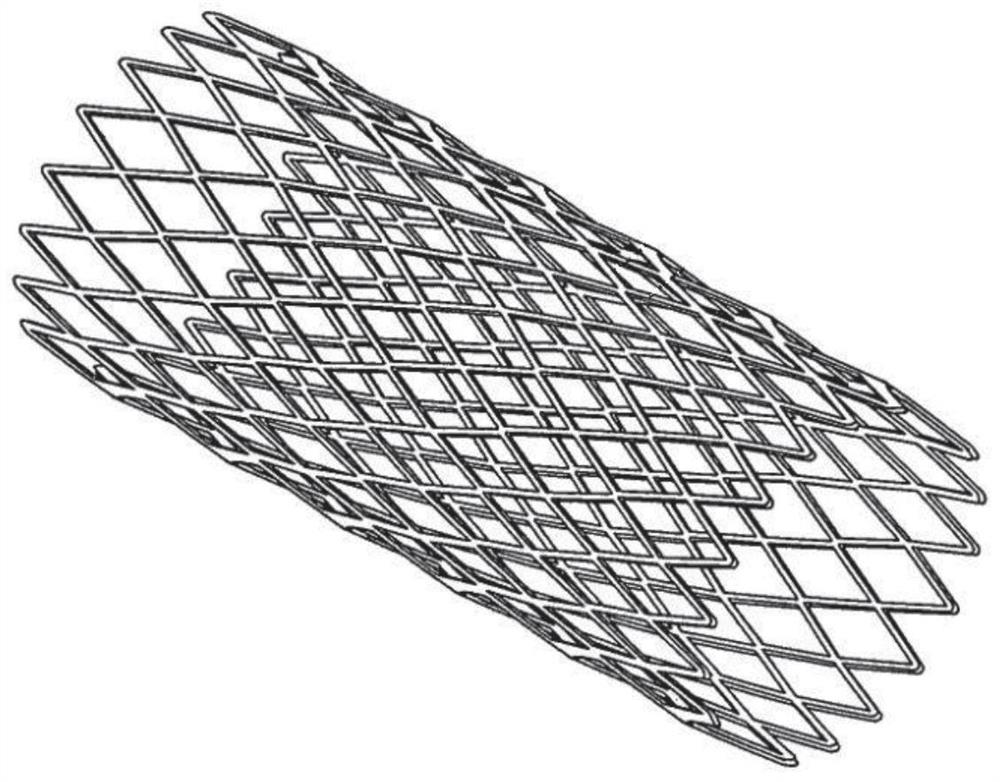

Embodiment 1

[0037] A nickel-titanium alloy material is selected to make a nickel-titanium stent. First, put the NiTi stent into a muffle furnace at 650 °C for 1 h for annealing. Recrystallize the internal structure of the nickel-titanium stent through annealing treatment, so that the internal structure of the nickel-titanium stent is completely uniform, eliminate defects such as dislocations in the nickel-titanium stent due to laser thermal stress during fabrication, and make the two-phase nano-scale precipitates melt back . Then put it into a muffle furnace at 300° C. for 20 hours of aging treatment, and make the nano two-phase precipitates uniformly disperse and precipitate again, and the medical device of the present invention can be obtained.

Embodiment 2

[0039] A nickel-titanium alloy material is selected to make a nickel-titanium stent. First, put the NiTi stent into a muffle furnace at 700°C for 0.5h for annealing. The annealing treatment recrystallizes the internal structure of the nickel-titanium stent, makes the internal structure of the nickel-titanium stent completely uniform, eliminates defects such as dislocations inside the stent, and makes the two-phase nanoscale precipitates dissolve back. Then put it into a muffle furnace at 300° C. for 20 hours of aging treatment, and make the nano two-phase precipitates uniformly disperse and precipitate again, and the medical device of the present invention can be obtained.

Embodiment 3

[0041] A nickel-titanium alloy material is selected to make a nickel-titanium stent. First, put the NiTi stent into a muffle furnace at 700°C for 0.5h for annealing. The annealing treatment recrystallizes the internal structure of the nickel-titanium stent, makes the internal structure of the nickel-titanium stent completely uniform, eliminates defects such as dislocations inside the stent, and makes the two-phase nanoscale precipitates dissolve back. Then put it into a muffle furnace at 250° C. for 24 hours of aging treatment, and make the nano two-phase precipitates uniformly disperse and precipitate again, and the medical device of the present invention can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com