A seed crystal preparation method and laying method for ingot single crystal

A laying method and seed crystal technology, applied in the direction of single crystal growth, chemical instruments and methods, manufacturing tools, etc., can solve the problems of dislocation reduction, inability to meet, and inability to consider dislocation nucleation and generation, etc., to eliminate Possibility, effect of removing dislocations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

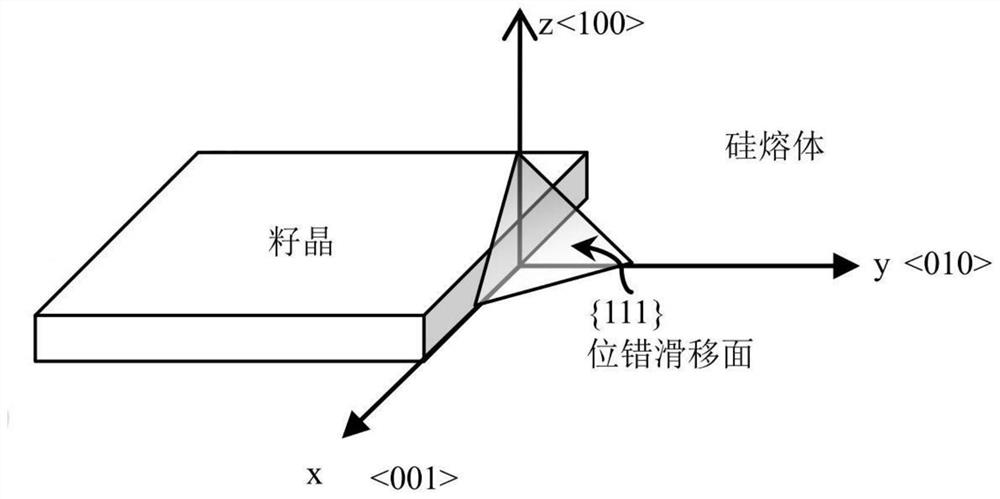

[0036] A method for preparing a seed crystal for ingot single crystal, according to the growth mode of single crystal silicon, growing according to a specific crystal orientation, cutting according to the specific crystal orientation, and then performing surface dislocation treatment, which specifically includes the following steps:

[0037] (1) In the seed crystal production stage, first determine the crystal orientation corresponding to the crystal growth direction (such as the crystal orientation), and perform vertical growth along the determined crystal growth direction, and use a dislocation-free single crystal (dislocation-free crystal). Density2 ), the seed crystal is grown into a bar; in the seed crystal production stage, the Czochralski single crystal method (CZ method) or the ingot single crystal method is used to produce the seed crystal. The diameter of the seed rod is as large as possible. Existing ingot diameters are mostly 6 inches or 8 inches, and there are al...

Embodiment example 1

[0057] 1) Using a single crystal furnace to draw a single crystal rod with a diameter of 252mm and a length of 2000 meters. After the dislocation test, the head and tail were cut off by 150mm to obtain a round rod with a length of 1700mm.

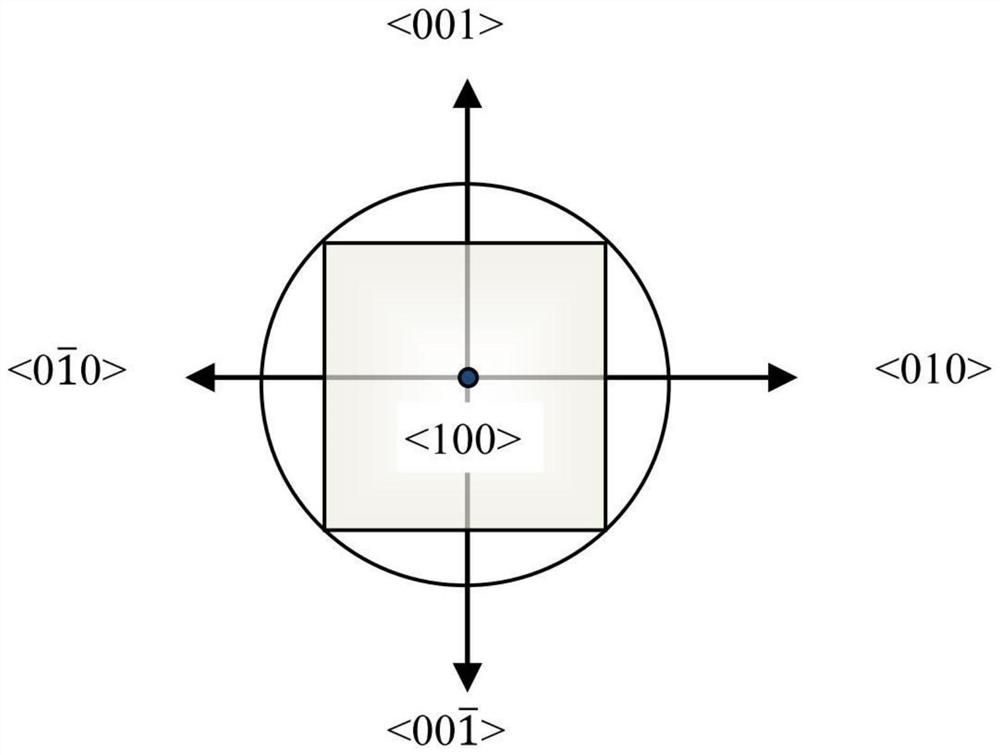

[0058] 2) Carry out the crystal orientation test on both ends and around the round bar to ensure: 1) The top is crystal orientation; 2) Measure {001}, {001 ̅}, {010}, {01 ̅0} around the bar The orientation of the four crystal planes, and draw the inscribed squares where these four crystal planes intersect with the end planes on the cross section (see image 3 ), the side length of the square is 180mm. Cut the round bar into square bars along the above four sections. The size of the square bar is 180x180x1700mm 3 .

[0059] 3) The silicon rod is cut into silicon blocks at intervals of 20mm along the direction of the crystal rod and perpendicular to the growth direction of the crystal rod, which is the blank of the seed crystal. The siz...

Embodiment example 2

[0062] 1) Using a single crystal furnace to draw a single crystal rod with a diameter of 300mm and a length of 1600 meters. After the dislocation test, the head and tail were cut by 150mm to obtain a round bar with a length of 1300mm.

[0063] 2) Carry out the crystal orientation test on both ends and around the round bar to ensure: 1) The top is crystal orientation; 2) Measure {001}, {001 ̅}, {010}, {01 ̅0} around the bar the directions of the four crystal planes, and draw the inscribed squares where these four crystal planes intersect with the end faces on the cross section (see image 3 ), the side length of the square is 214mm. Cut the round bar into square bars along the four sides of the inscribed square on the above-mentioned end face. The size of the square bar is: 214x214x1300mm 3 .

[0064] 3) The silicon rod is cut into silicon blocks at intervals of 26mm along the crystal rod direction and perpendicular to the growth direction of the crystal rod, which is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com