Secondary hot-extrusion technology of AQ80M magnesium alloy profiles

A magnesium alloy and hot extrusion technology, which is applied in the field of secondary hot extrusion of AQ80M magnesium alloy profiles, can solve problems such as limiting the application of magnesium alloys, poor plastic deformation ability, and limited texture strength of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

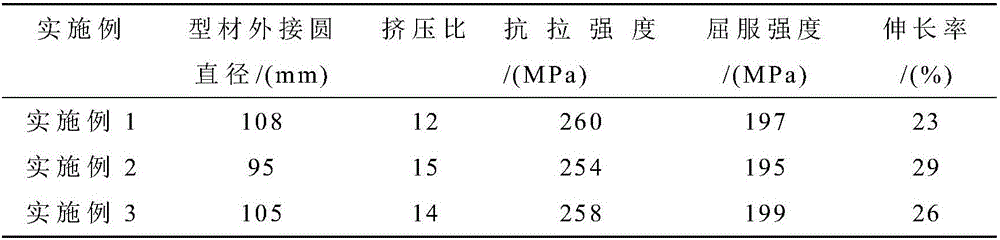

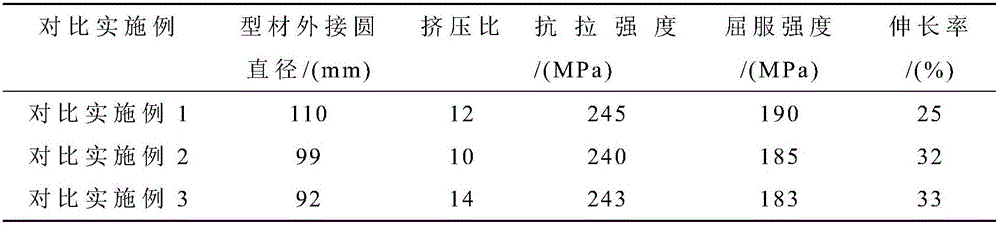

Embodiment 1

[0023] In this example, the ingot is melted by a large-capacity furnace, cast semi-continuously, and turned and peeled to obtain an ingot with a specification of Φ580mm and a length of 1500mm. Chemical treatment; then heat the extrusion die and extrusion barrel, the mold temperature is 380°C, the extrusion barrel temperature is 420°C, and then the magnesium alloy billet is heated to 380°C and kept for 3 hours, then put into the extrusion barrel, and the 10000T horizontal hydraulic press Extrude on the top to obtain a primary extruded bar, the extrusion ratio is 2, and the exit speed is 6mm / s; the primary extruded bar with a length of 600mm after sawing and blanking is kept at 380°C for 3h, and extruded at 380°C The secondary extrusion is carried out inside the cylinder and the mold, the extrusion ratio is 12, the exit speed is 12mm / s, the diameter of the circumscribed circle of the triangular profile after extrusion is 108mm, and the length is ≥5000mm. After extrusion, the prof...

Embodiment 2

[0027] In this embodiment, the ingot is melted by a large-capacity furnace, and after semi-continuous casting, the ingot size is Φ570 mm and the length is 1500 mm after turning and peeling. Homogenization treatment; then heat the extrusion die and extrusion barrel, the temperature of the mold is 340°C, the temperature of the extrusion barrel is 380°C, and then the magnesium alloy billet is heated to 340°C for 1 hour and then put into the extrusion barrel. Extrude on a hydraulic press to obtain a primary extruded bar with an extrusion ratio of 9 and an exit speed of 1.5 mm / s. The primary extruded bar with a length of 800 mm after sawing and blanking is kept at 340°C for 1 hour, and then heated at 360°C. Extrusion inside the extrusion barrel and mold, extrusion ratio 15, exit speed 4mm / s, extruded triangular profile circumscribed circle diameter 95mm, length ≥ 5000mm, extruded profile kept at 410°C for 1 hour, then cooled at 200°C After isothermal aging heat treatment for 20 h, ...

Embodiment 3

[0031] In this example, the ingot is melted by a large-capacity furnace, and after semi-continuous casting, the ingot size is Φ580 mm and the length is 1500 mm after turning and peeling. Homogenization treatment; then heat the extrusion die and extrusion cylinder, the temperature of the mold is 420°C, the temperature of the extrusion cylinder is 340°C, and then the magnesium alloy billet is heated to 420°C for 1 hour and then put into the extrusion cylinder. Extruded on a hydraulic press to obtain a primary extruded bar, the extrusion ratio is 6, and the exit speed is 3mm / s; the primary extruded bar with a length of 400mm after sawing and blanking is kept at 360°C for 2h, and extruded at 340°C Extrude inside the cylinder and the mold, the extrusion ratio is 14, the exit speed is 4mm / s, the diameter of the circumscribed circle of the triangular profile after extrusion is 105mm, and the length is ≥5000mm. After the isothermal aging heat treatment for 40h, the mechanical properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com