Alloy brazing filler metal for vacuum sealing and connection

A technology of alloy solder and vacuum, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve problems such as difficult to meet the requirements, achieve the effect of improving processing performance and preventing CuIn brittle mesophase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

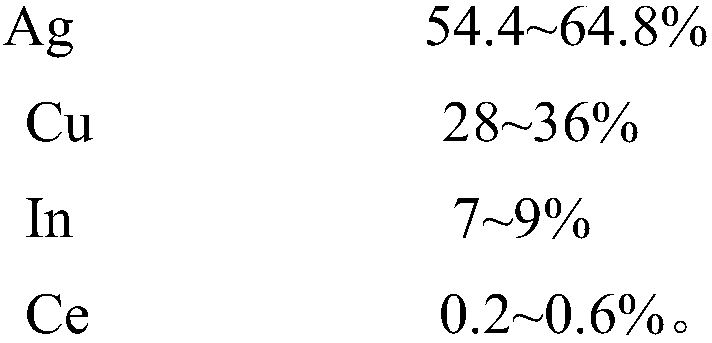

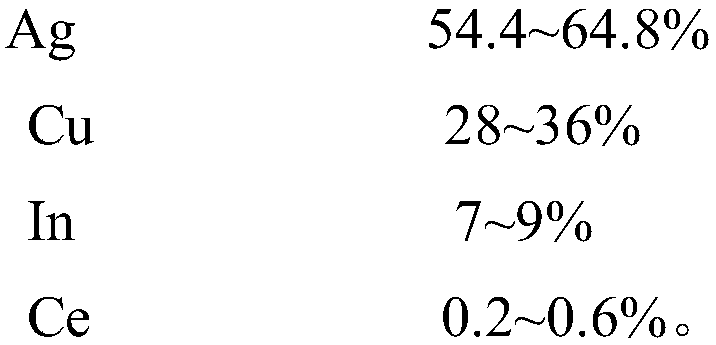

[0020] A kind of alloy solder for vacuum sealing, each metal element composition is as shown in table 1, and its preparation method comprises the steps:

[0021] (1) put the purity 99.99% Ag and the purity 99.9% Cu, In, Ce into the vacuum smelting furnace according to the ratio, after the vacuum degree in the furnace is evacuated to 0.02Pa, the furnace is heated to 1200°C, kept for 30 minutes, and The alloy liquid is cast into the setting mold;

[0022] (2) Carry out vacuum annealing to the ingot after casting, the annealing temperature is 500 ℃, heat preservation 3h, naturally cool to room temperature and take out;

[0023] (3) Cold-roll the 5mm strip of the ingot after the annealing treatment in step (2), and then anneal at a temperature of 600° C. for a holding time of 2 hours, fill in an inert gas, and naturally cool to room temperature and take it out;

[0024] (4) Continue rolling the strip after the annealing treatment in step (3) to 2mm, anneal it at a temperature of ...

Embodiment 2

[0026] A kind of alloy solder for vacuum sealing, each metal element composition is as shown in table 1, and its preparation method comprises the steps:

[0027] (1) put the purity 99.99% Ag and the purity 99.9% Cu, In, Ce into the vacuum smelting furnace according to the ratio, after the vacuum degree in the furnace is evacuated to 0.04Pa, the furnace is heated to 1250°C and kept for 35 minutes. The alloy liquid is cast into the setting mold;

[0028] (2) Carry out vacuum annealing to the ingot after casting, the annealing temperature is 520 ℃, heat preservation 3.5h, naturally cool to room temperature and take out;

[0029] (3) Cold-roll the 5mm strip of the ingot after the annealing treatment in step (2), and then anneal at a temperature of 600° C. to 630° C. for a holding time of 2.5 hours, fill it with an inert gas, and naturally cool to room temperature and take it out;

[0030] (4) Continue rolling the strip after the annealing treatment in step (3) to 2mm, anneal at a...

Embodiment 3

[0032] A kind of alloy solder for vacuum sealing, each metal element composition is as shown in table 1, and its preparation method comprises the steps:

[0033] (1) Put the purity of 99.99% Ag and the purity of 99.9% Cu, In and Ce into the vacuum smelting furnace according to the ratio. After the vacuum degree in the furnace is evacuated to 0.4Pa, the furnace is heated to 1300 ° C and kept for 40 minutes. The alloy liquid is cast into the setting mold;

[0034] (2) Carry out vacuum annealing to the ingot after casting, the annealing temperature is 550 ℃, heat preservation 4h, naturally cool to room temperature and take out;

[0035] (3) Cold-roll the 6mm strip of the cast ingot after the annealing treatment in step (2), then anneal at a temperature of 650° C., hold for 3 hours, fill in an inert gas, and take it out after naturally cooling to room temperature;

[0036] (4) Continue rolling the strip after the annealing treatment in step (3) to 3mm, anneal at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com