Substrate with self-stripping function and method for stripping epitaxial layer

An epitaxial layer, self-stripping technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problem of low cost, achieve the effect of short process cycle, low cost, and not easy to surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

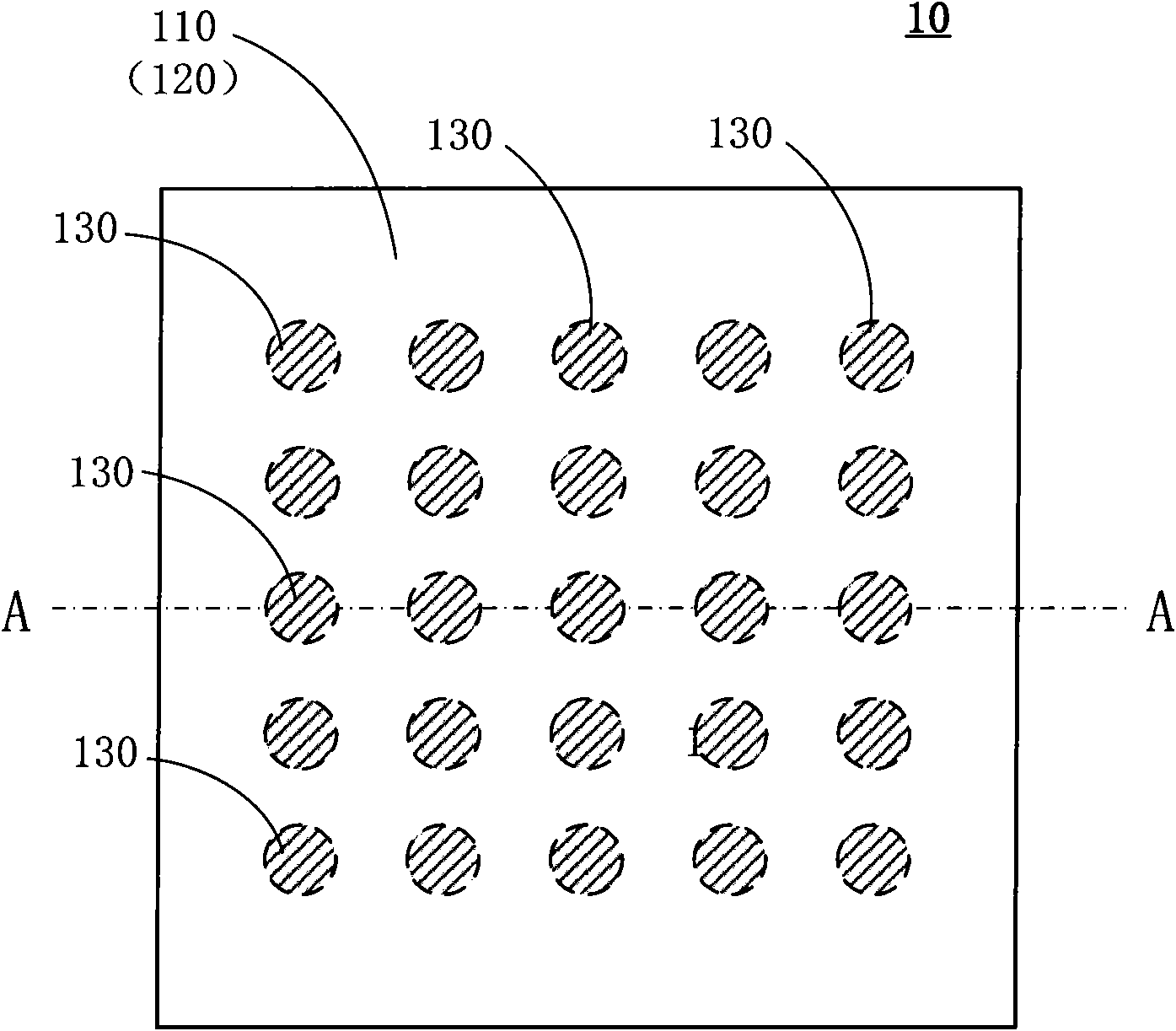

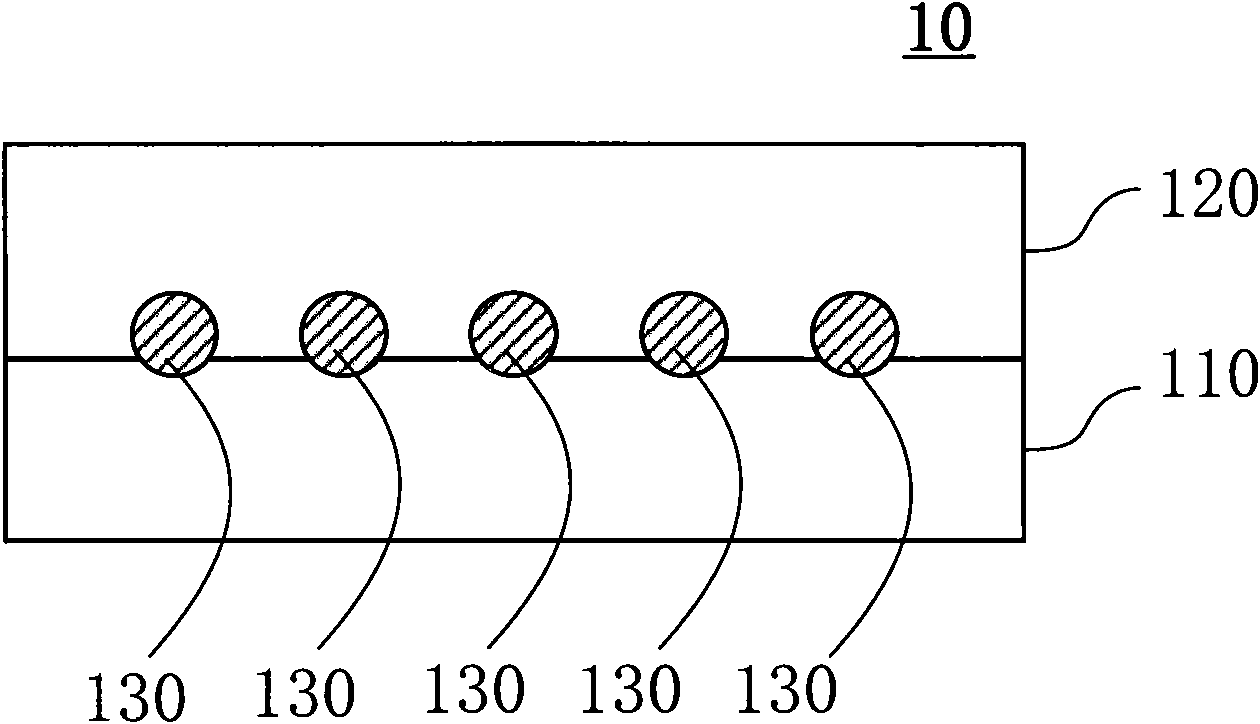

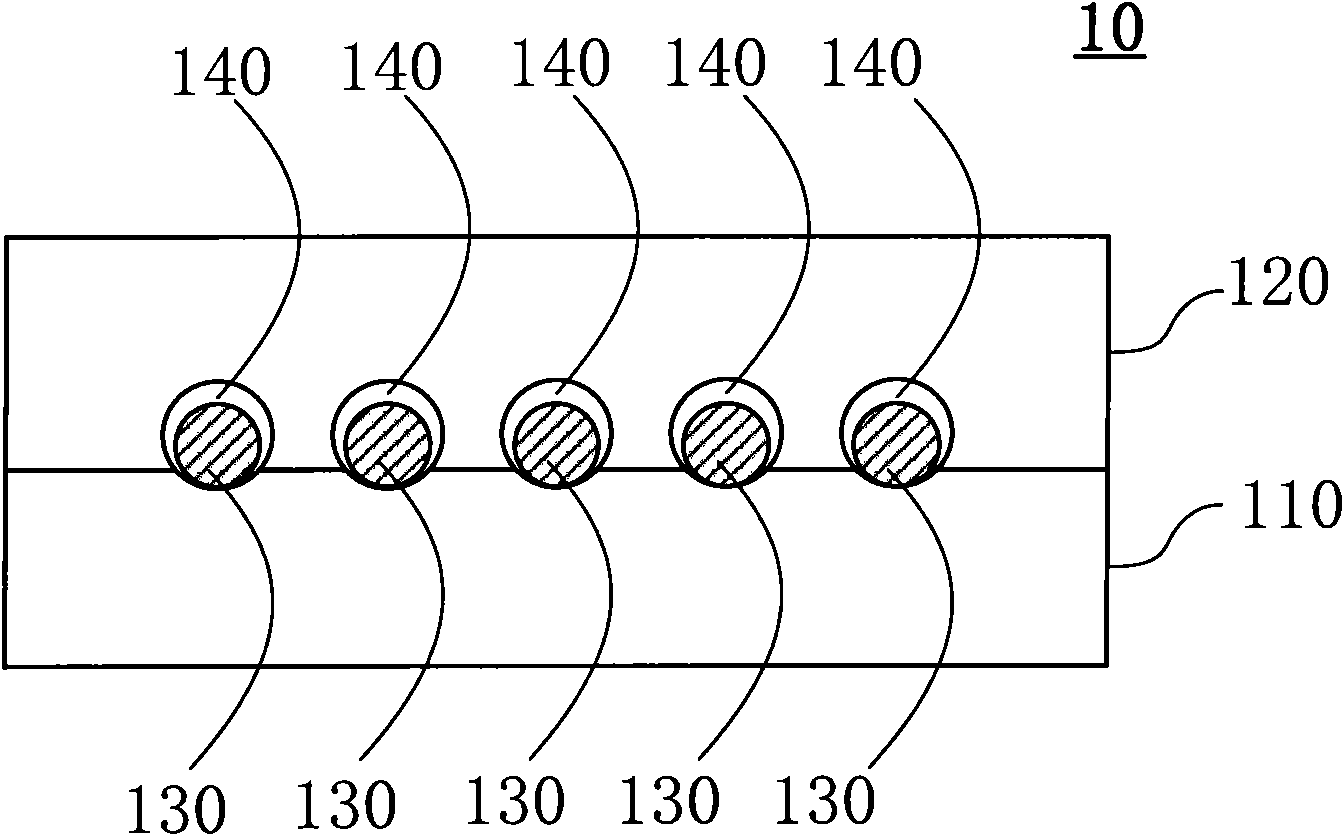

[0053] attached Figure 5 Shown is a schematic diagram of the implementation steps of this specific embodiment, including; step S20, providing a support substrate; step S21, forming a plurality of thermoelastic bodies on the surface of the support substrate, and the plurality of thermoelastomers are formed on the surface of the support substrate Two-dimensional distribution; step S22, further forming an epitaxial layer on the surface of the support substrate formed with a plurality of thermoelastomers, and the epitaxial layer completely covers the surface of the thermoelastomer and the support substrate; step S23, raising the temperature of the system, A cavity is formed at the position of the thermoelastomer; step S24, applying a shear force between the epitaxial layer and the supporting substrate to separate them; step S25, removing the thermoelastomer attached to the surface of the epitaxial layer.

[0054] In this specific embodiment, the thermoelastic body 130 is a plural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com