kitchen water-based facial mask

A mask liquid, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of unsightly, flammable cling film, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

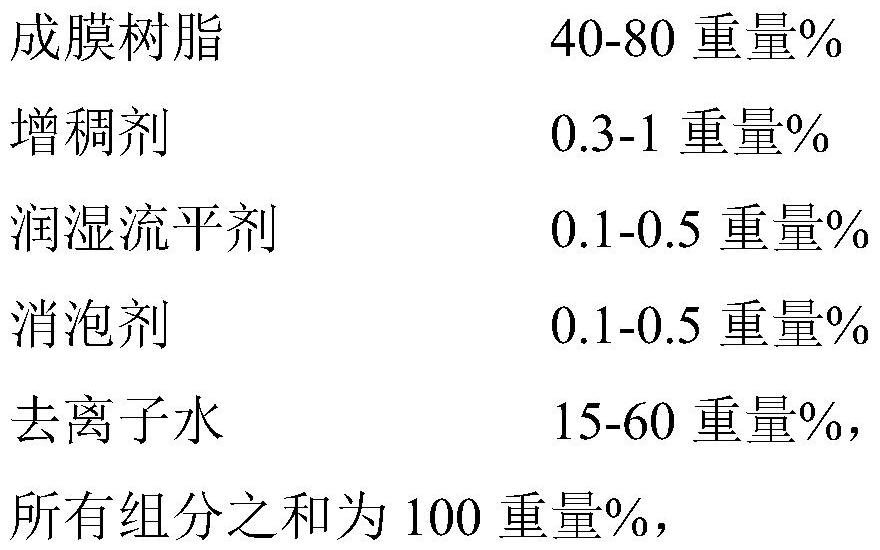

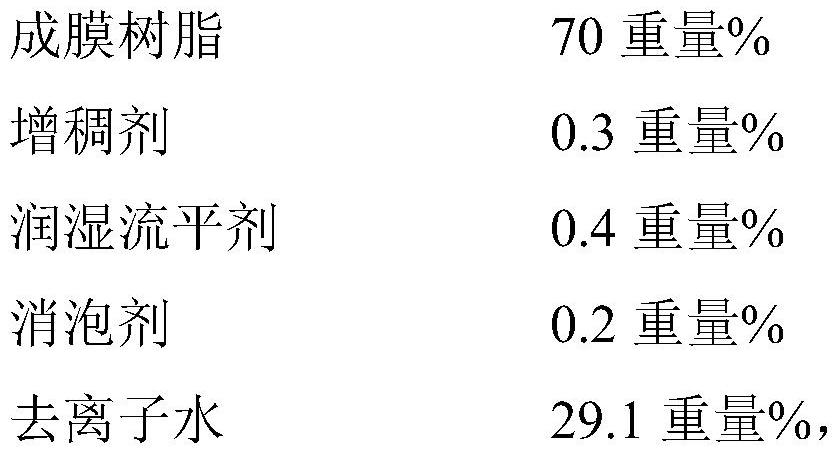

Method used

Image

Examples

preparation example Construction

[0033] The invention also relates to a preparation method of the kitchen water-based mask liquid. The preparation process comprises the following steps: accurately weighing the film-forming resin in a beaker, adding deionized water, and stirring evenly. In the state of stirring, add wetting and leveling agent, defoamer and thickener accordingly, and stir at room temperature for 10-30 minutes to obtain the kitchen water-based mask liquid.

[0034] Compared with existing kitchen like products, the kitchen water-based mask liquid of the present invention has the following advantages:

[0035] Water-based non-toxic, low VOC;

[0036] Brush or spray directly for easy application. The area and shape of brushing or spraying can be freely controlled;

[0037] The product is mild, safe and non-irritating;

[0038] Will not burn, no fire hazard;

[0039] Non-corrosive to the surface of tiles or range hoods;

[0040] The cured film is ultra-thin and transparent, and does not affect...

Embodiment 1-4

[0048] Embodiment 1-4: Screening of film-forming resin

[0049] Examples 1-4 describe the screening process for film-forming resins.

[0050] The preparation method is as follows: Accurately weigh water-based polyurethane (the type of film-forming resin is shown in Table 1 below) in a beaker, add deionized water, and stir evenly. In the state of stirring, add BYK-348, BYK-018, BYK-425 accordingly, and stir for 10 minutes at room temperature to prepare a kitchen mask liquid, which is set aside.

[0051] Table 1

[0052]

[0053] Evaluation example 1:

[0054] Evaluation method:

[0055] Membrane peeling off: 1-5 points are set according to the difficulty of peeling off, 1 is almost impossible to peel off, 5 is easy and the whole piece is completely peeled off. Rated by at least 3 people, take the average.

[0056] Film transparency: After peeling off the cured coating film, measure the light transmittance of the coating film with a spectrophotometer. 75%-80% (excluding...

Embodiment 5-8

[0061] Embodiment 5-8: the screening of thickener

[0062] Preparation method: Accurately weigh water-based polyurethane in a beaker, add deionized water, and stir evenly. In the state of stirring, add BYK-348, BYK-018, Seppic USPI (or BYK-420 or BYK-425 or magnesium aluminum silicate or EZ-5) according to this, and stir for 10 minutes at room temperature to prepare a kitchen mask liquid, which is set aside .

[0063] Table 2

[0064]

[0065]

[0066] Evaluation example 2:

[0067] The evaluation method is the same as the method in evaluation example 1:

[0068] Example 4 Example 5 Example 6 Example 7 Example 8 Coating method spraying spraying spraying spraying spraying Membrane peeling 5 4 5 4 4 film transparency 4 3 4 2 2 Leveling 4 4 4 3 4 Sag resistance 4 5 3 3 3

[0069] The results show that if transparency is not an important requirement, all of Examples 4-8 can meet the product re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com