Electrochemistry cutting method of paddle nickel-coated piece

A cutting method, electrochemical technology, applied in the direction of processing working media, etc., can solve problems such as edge defects, slow cutting speed, etc., and achieve uniform cutting edges, fast drying, and good protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1:

[0033] When hanging outside the reserved area, punch a hole of Φ3 at the highest point → hook up → pickling → water washing → drying → brush release agent → dip coating insulating protective material LTZ-230 → drying → dismantling → engraving → hooking → electric Chemical cutting → washing → drying → disassembly → peeling off insulating protective material → grinding → inspection.

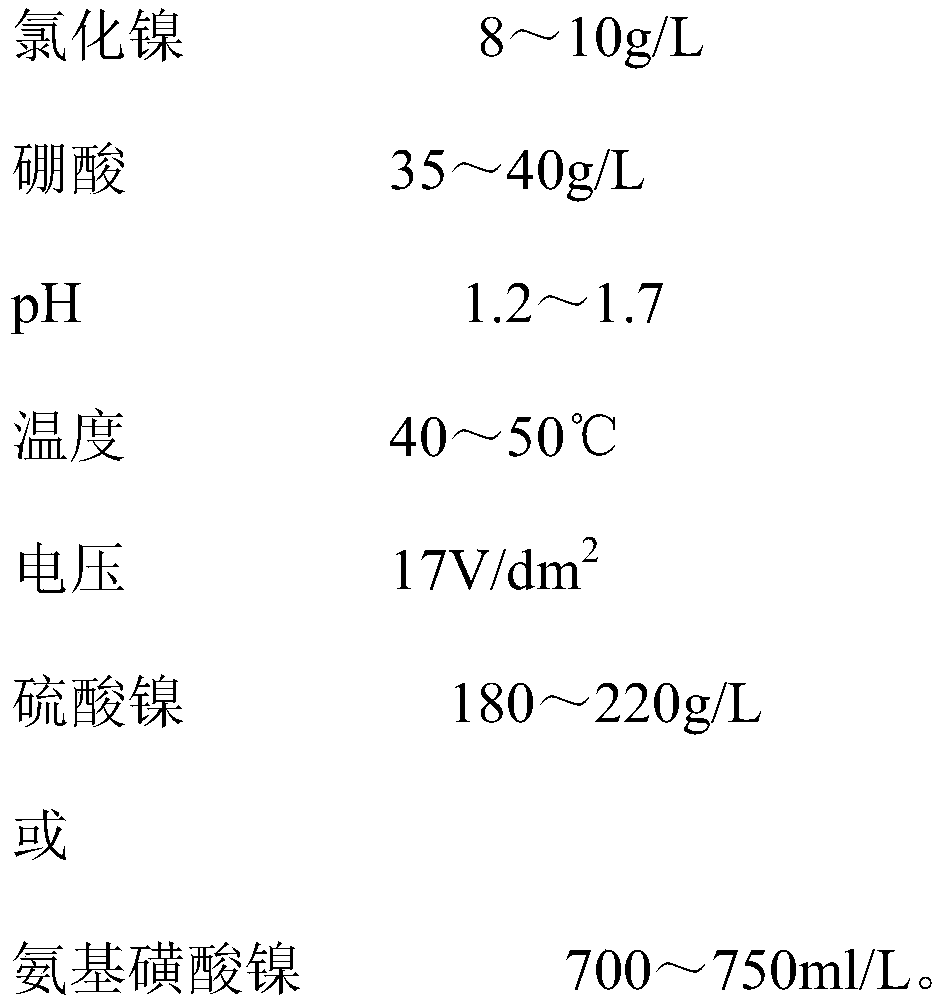

[0034] The punching position of the electroformed nickel cladding sheet ensures the highest point, and pay attention not to be immersed in the bath during electrochemical cutting. Before dipping the insulating protective material, stick the parts to be cut with tape, then dipping the insulating protective material LTZ-230 five times with an interval of 15 minutes, and finally dry for 12 hours, with a dry film thickness of 0.25 mm; After the tape is lightly scratched, tear off the tape; use copper wire to hang the nickel-coated sheet for electric cutting in formula 1, and the cu...

Example Embodiment

[0051] Embodiment 2:

[0052] When hanging outside the reserved area, punch a hole of Φ3 at the highest point → hook up → pickling → water washing → drying → brush release agent → dip coating insulating protective material LTZ-230 → drying → dismantling → engraving → hooking → electric Chemical cutting → washing → drying → disassembly → peeling off insulating protective material → grinding → inspection.

[0053] The punching position of the electroformed nickel cladding sheet ensures the highest point, and pay attention not to be immersed in the bath during electrochemical cutting. Before dipping the insulating protective material, stick the parts to be cut with tape, then dipping the insulating protective material LTZ-230 five times with an interval of 15 minutes, and finally dry for 12 hours, and the dry film thickness is 0.26mm; After the tape is lightly scratched, tear off the tape; use copper wire to hang the nickel-coated sheet for electric cutting in formula 2, and the...

Example Embodiment

[0070] Embodiment three:

[0071] When hanging outside the reserved area, punch a hole of Φ3 at the highest point → fasten → pickling → water washing → drying → brush release agent → dip coating insulating protective material LTZ-230 → drying → dismantling → engraving → hanging → electric Chemical cutting → washing → drying → disassembly → peeling off insulating protective material → grinding → inspection. .

[0072]The punching position of the electroformed nickel cladding sheet ensures the highest point, and pay attention not to be immersed in the bath during electrochemical cutting. Before dipping the insulating protective material, stick the parts to be cut with tape, then dipping the insulating protective material LTZ-230 six times with an interval of 20 minutes, and finally dry for 12 hours, and the dry film thickness is 0.35mm; After the tape is lightly scratched, tear off the tape; use copper wire to hang the nickel-coated sheet for electric cutting in formula 1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Dry film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com