Chopping type micro cane harvesting machine

A harvester and sugarcane technology, which is applied in the direction of harvesters, lifting devices of agricultural machinery, agricultural machinery and implements, etc., can solve the problems of incompatibility of sugarcane harvesters, low harvesting efficiency, and large damage to sugarcane and cane roots, so as to provide stable work. The effect of high cutting efficiency, high cutting efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

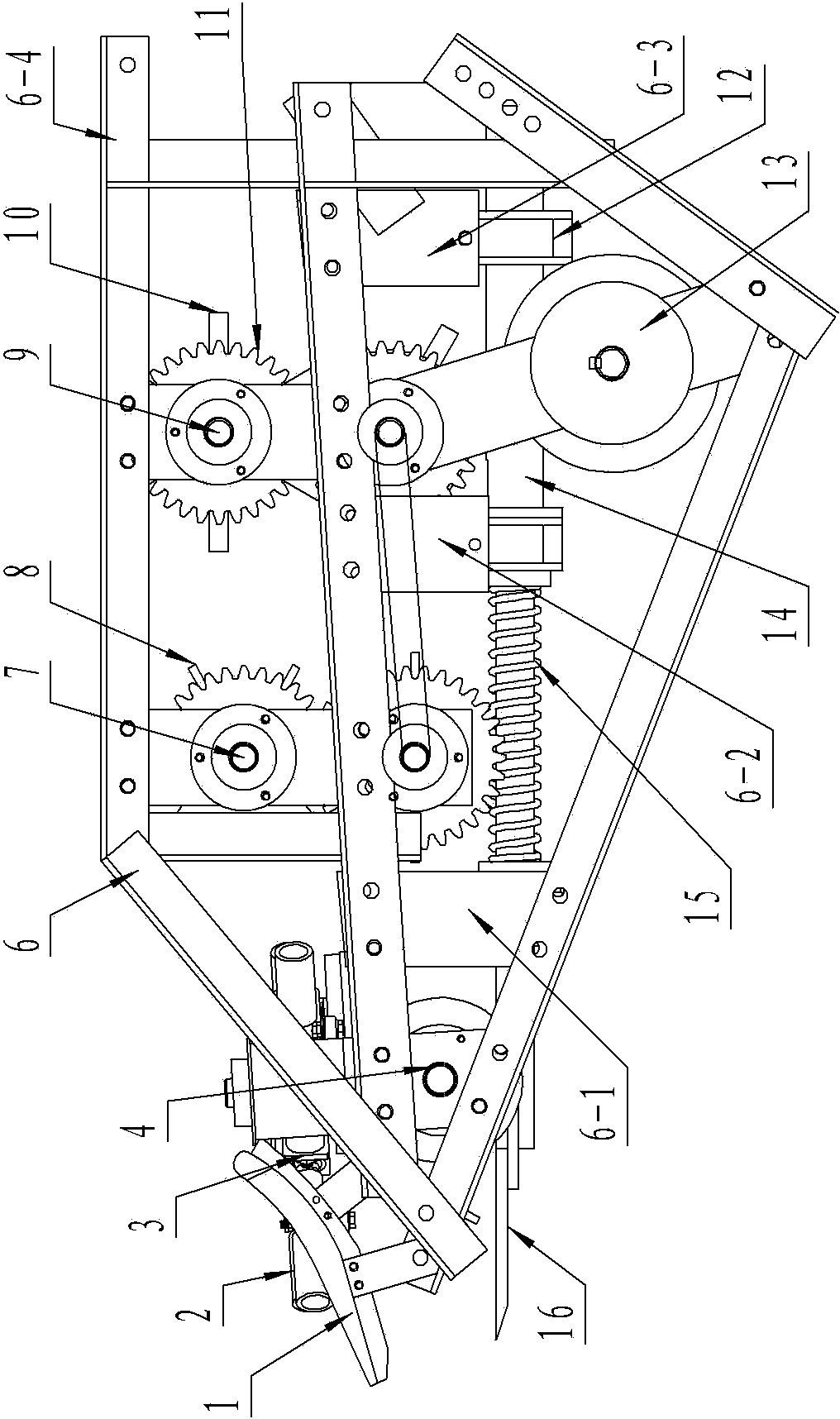

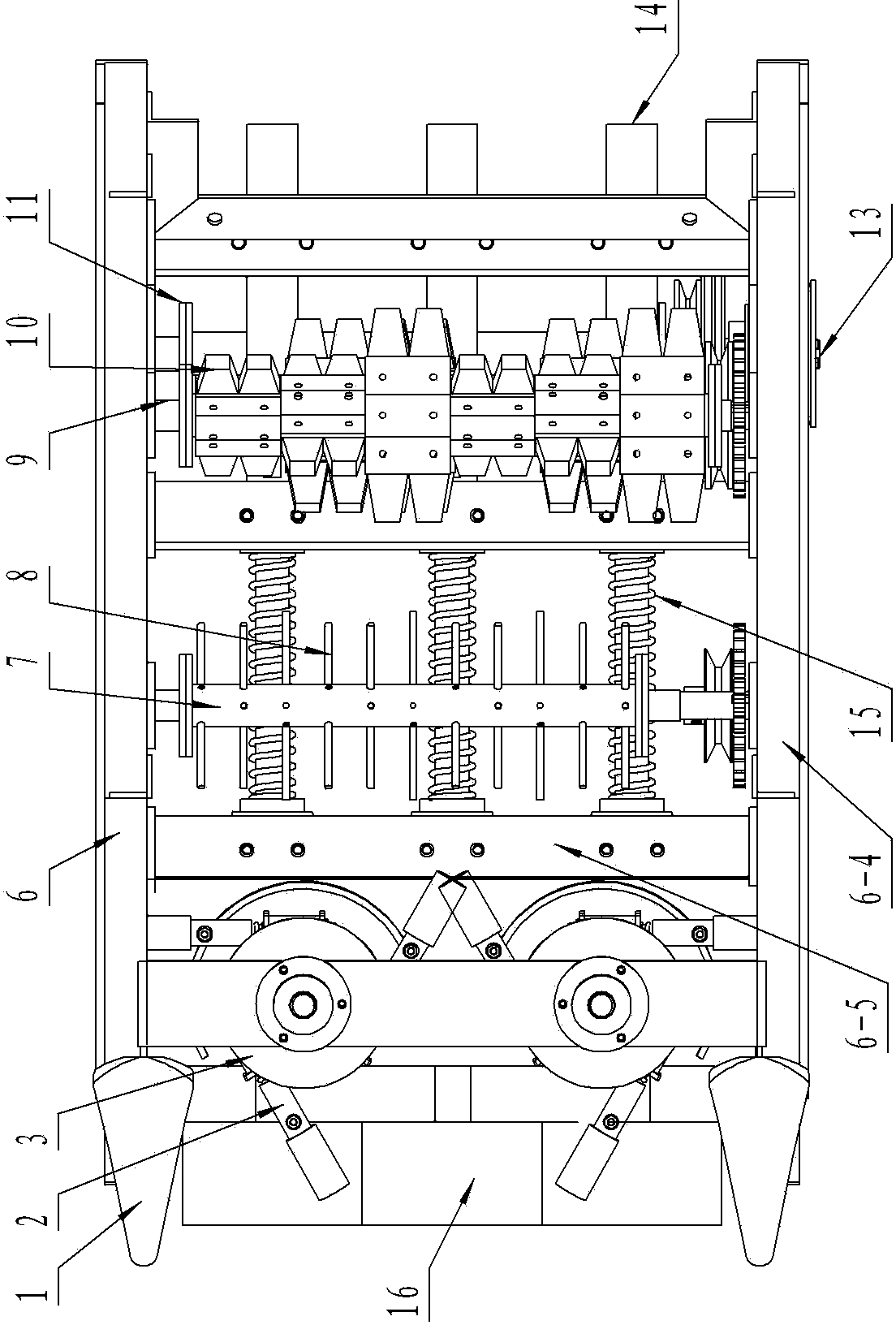

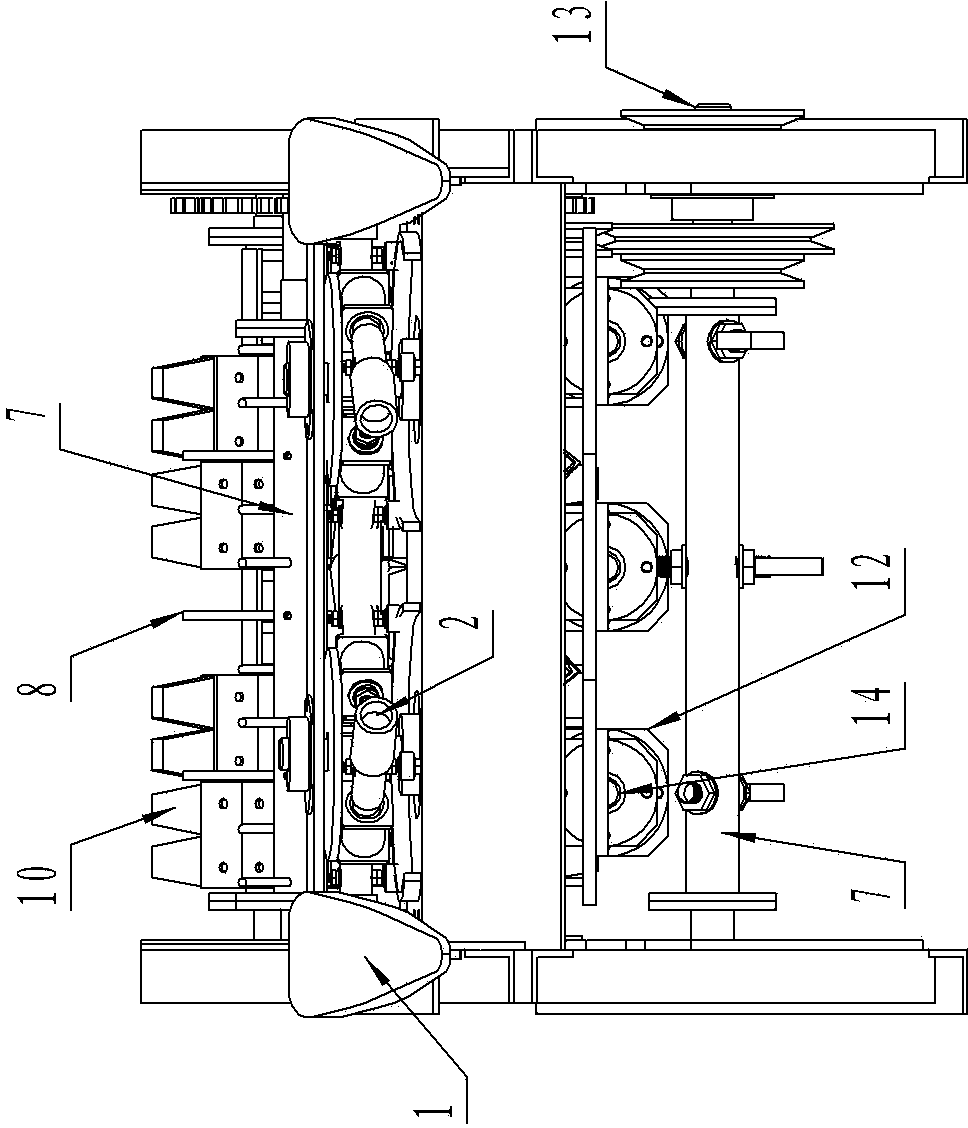

[0022] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0023] Such as Figure 1 to Figure 7 Shown this cut type miniature sugarcane harvester, it comprises vehicle frame 6, and vehicle frame 6 comprises two crossbeams 6-4, three longitudinal beams 6-5 and many vertical beams and inclined beams and constitutes, vehicle frame 6 It is equipped with stripping device and cutting device.

[0024] Cutting device comprises three guide rods 14 movable across from front to back at vehicle frame 6 three vertical beams 6-1,6-2,6-3 bottom, guide rod 14 and three vertical beams 6-1,6-2,6- 3. Connected by the sliding bearing seat and the bearing 12, the guide rod 14 is provided with a spring 15 between a vertical beam 6-1 at the front end and a vertical beam 6-2 at the second front end outside the guide rod 14, and a spring 15 is provided at the front end of the guide rod 14 for cutting sugarcane. The cutting knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com