H13 steel hard surface surfacing layer heat treatment method

A heat treatment method and surfacing layer technology, applied in heat treatment furnaces, heat treatment equipment, welding equipment, etc., can solve problems such as the influence of mechanical properties of surfacing layers, uneven tissue composition, and dislocations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Cut the H13 steel with a wire cutting machine as the welding matrix. Before surfacing, the sample is mechanically ground with 400 mesh, 600 mesh, 800 mesh and 1000 mesh sandpaper, rinsed with tap water, placed in absolute ethanol for ultrasonic vibration to remove the particles attached to the surface, and after drying, ultrasonically cleaned in sodium hydroxide to remove The grease on the surface of the sample was finally rinsed with distilled water, ultrasonically oscillated with anhydrous ethanol, dried, and set aside.

[0022] (2) Overlay welding: the preheating temperature is 250-300°C, the interlayer temperature is 200-250°C, the wire diameter is 1.2mm, the welding current is 100-140A, the arc voltage is 17-25V, and the welding speed is 5mm / s , The polarity of the power supply is DC reversed. Chemical composition of hardfacing layer: C 0.03-0.07%, Si 0.40-0.60%, Mn 1.00-1.35%, Cr 9.50-13.50%, Mo 0.30-0.65%, V 0.06-0.15%, Ni 1.15-1.80%. The hardness and wear ...

Embodiment 2

[0027] (1) With embodiment 1.

[0028] (2) With embodiment 1.

[0029] (3) with embodiment 1.

[0030] (4) Heat treatment: Temper the processed mold and cool it to room temperature in air to obtain the finished product. The tempering temperature is 450°C, the holding time is 1h, and the heating rate is 10°C / min.

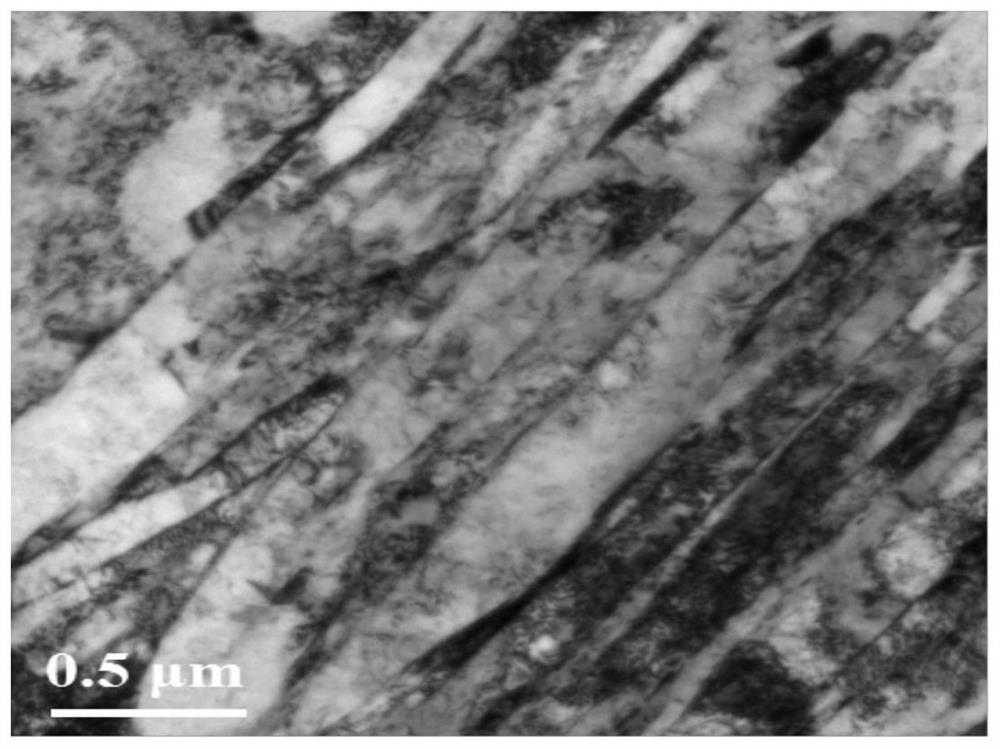

[0031] (5) Observation by transmission electron microscope of the hard surface welding layer obtained by the above steps shows that the structure of the welding layer is refined, welding defects are reduced, and no "secondary hardening" occurs. The hardness of the surfacing layer is 330.8±6.4HV 0.2 . After the friction and wear test, the mass loss of the surfacing layer was 14.9±0.2mg.

Embodiment 3

[0033] (1) With embodiment 1.

[0034] (2) With embodiment 1.

[0035] (3) with embodiment 1.

[0036] (4) Heat treatment: Temper the processed mold and cool it to room temperature in air to obtain the finished product. The tempering temperature is 450°C, the holding time is 2h, and the heating rate is 10°C / min.

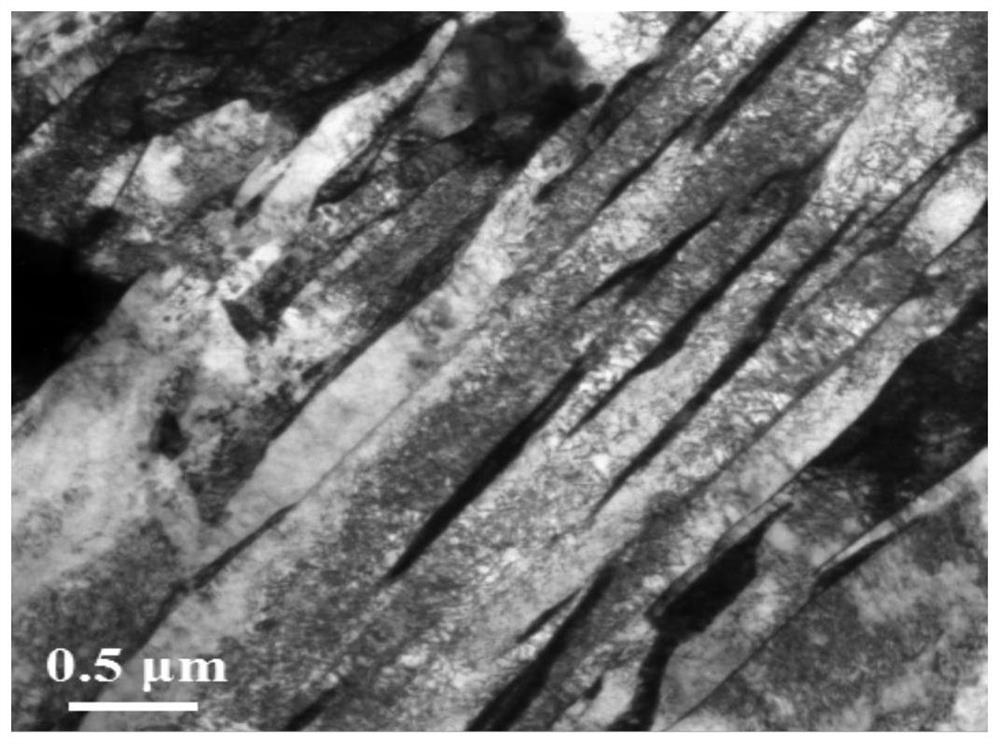

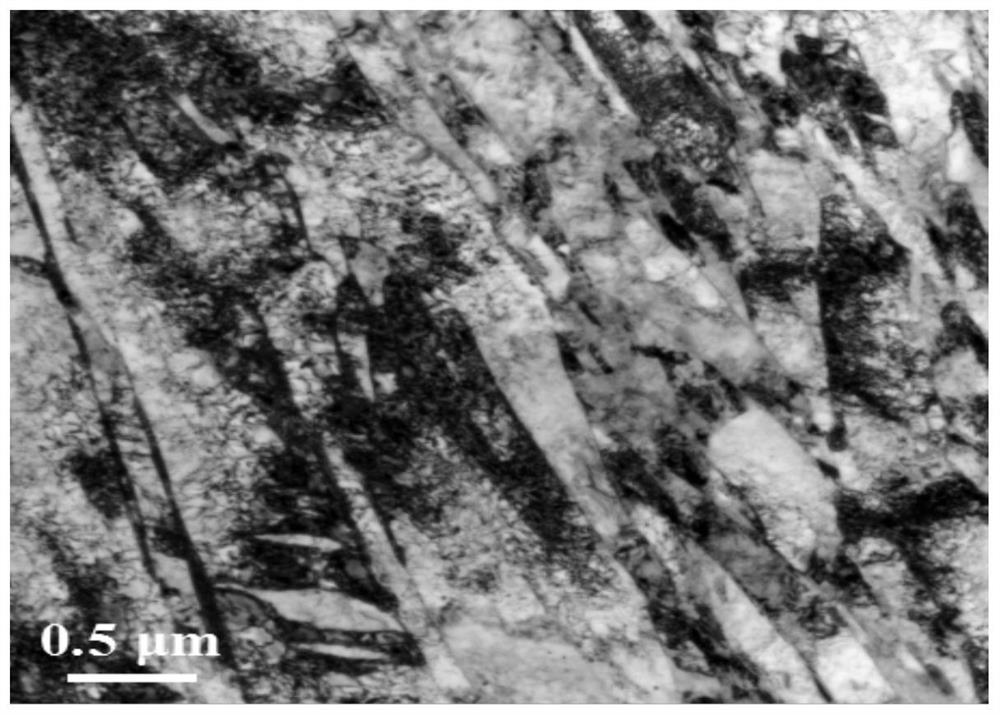

[0037] (5) Observation by transmission electron microscope of the hard surface welding layer obtained by the above steps shows that the structure of the welding layer is refined, welding defects are reduced, and the effect of "secondary hardening" is obvious. The hardness of the surfacing layer is 370.0±6.3HV 0.2 . After the friction and wear test, the mass loss of the surfacing layer was 11.8±1.3mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com