External grinding machining device for thin-wall non-metal part with inner ring groove and clamping method

A cylindrical grinding and processing device technology, applied in metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc. Unreasonable, difficult to guarantee the design size of parts, etc., to improve the clamping deformation method, prevent uneven grinding force, and improve the processing qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

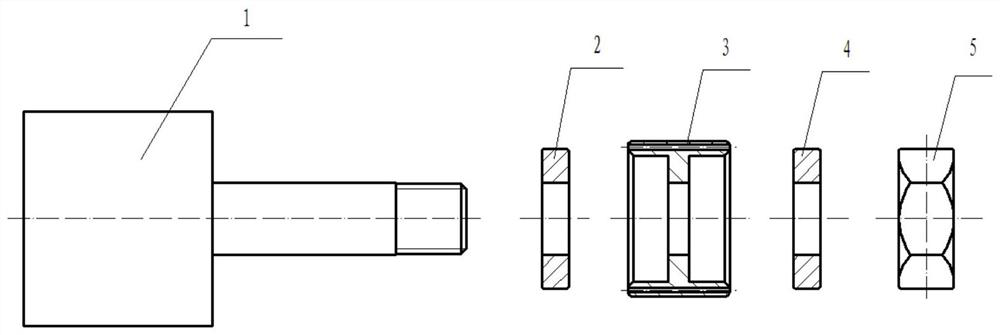

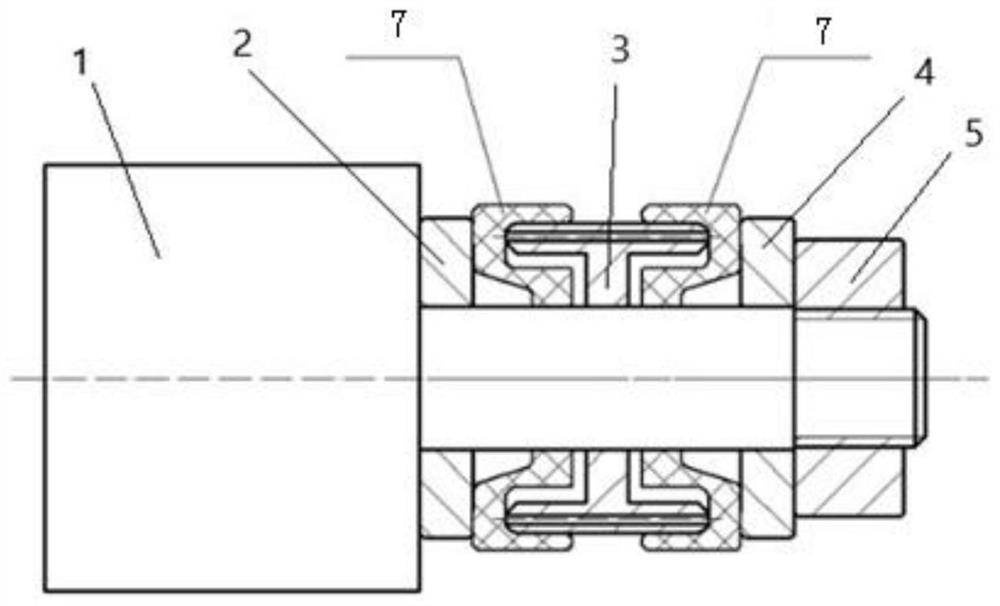

[0042] see figure 1 and figure 2 , in this embodiment, the mandrel 1 is a steel mandrel with threads and top holes, the mandrel 1 includes the middle polished rod part and the shoulders and threaded parts respectively located at both ends of the polished rod part, and the mandrel 1 shoulder carries out the shaft To the limit, the first gasket, the thin-walled non-metallic part 7 to be processed, the bushing 3 and the second gasket 4 are installed on the polished rod of the mandrel, and the threaded part is clamped with the nut 5. Tightness control.

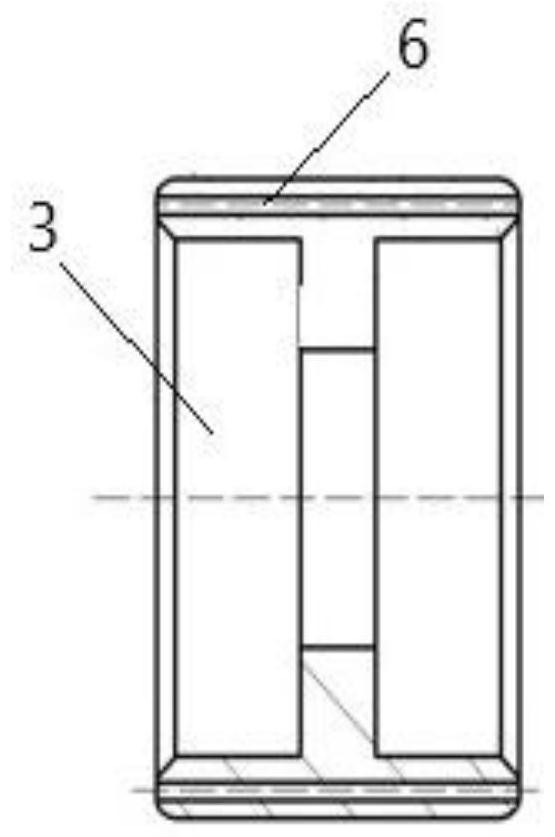

[0043] see image 3 , in this embodiment, the bushing 3 is a two-way concave bushing with vent holes. Extending inwardly, the longitudinal section of the bushing 3 is I-shaped.

[0044] In this embodiment, the outer circle of the bushing 3 matches the major diameter of the annular groove of the part, the diameter of the inner wall of the bushing 3 is at least 1mm smaller than the minor diameter of the inner ring groove of the...

Embodiment 2

[0063] like figure 2 As shown, the thin-walled non-metallic part 1 with an inner ring groove to be processed (the outer diameter of the part is Φ35.5mm, the major diameter of the inner ring groove is Φ30mm, the minor diameter of the inner ring groove is Φ21mm, the hole diameter is Φ13.5mm, and the material is rubber ) into one end of the two-way concave bushing, put part 2 into the other end of the bushing, the outer circle of the bushing matches the major diameter of the ring groove of the part, and the diameter of the inner wall of the bushing is smaller than the minor diameter of the inner ring groove of the thin-walled non-metallic part 7 to be processed At least 1mm, the bushing hole is matched with the mandrel, the depth from the end surface of the bushing to the bottom of the groove is at least 2mm greater than the depth of the annular groove of the part, to ensure that the bottom of the annular groove of the part and the end surface of the bushing 3 are tightly positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com