Power output device of non-road diesel engine

A power output, diesel engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problem that the power transmission mechanism cannot serve the agricultural engineering machinery market well, is easily involved in harvests, debris, industrial dust, and poor transmission stability and other problems, to achieve the effect of simple structure, ensuring stability and enhancing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

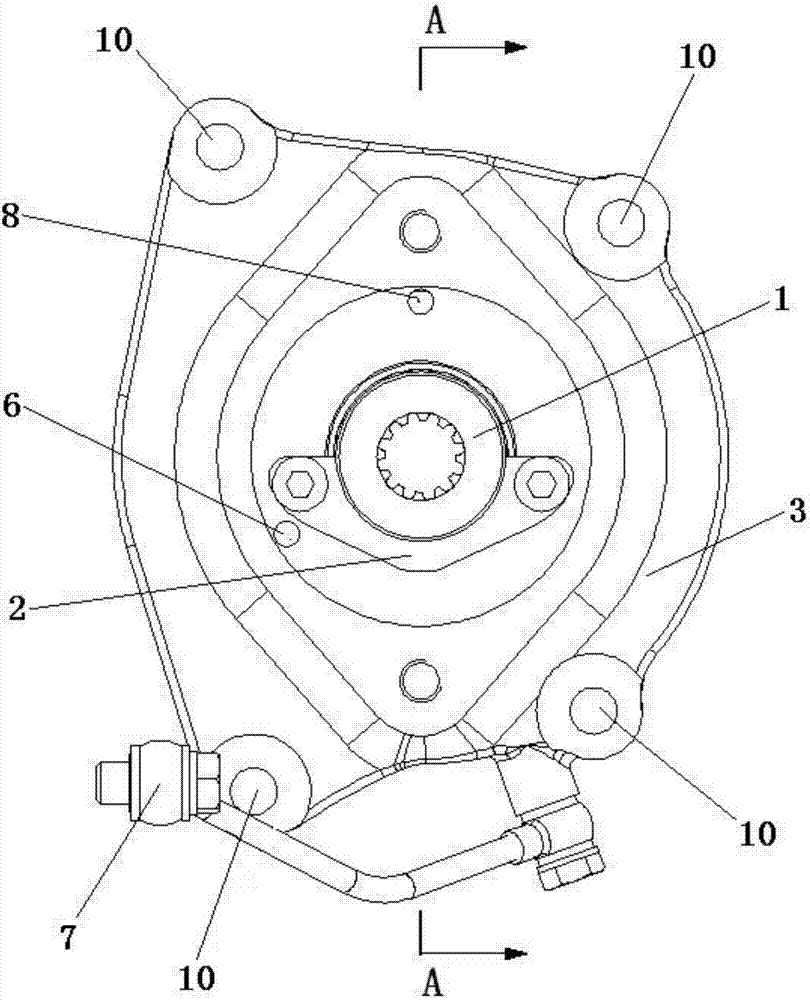

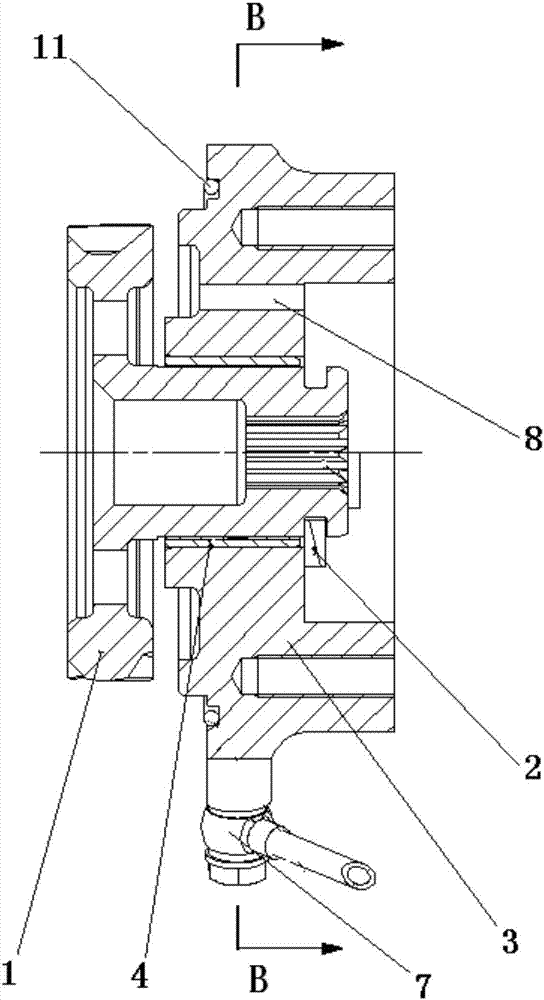

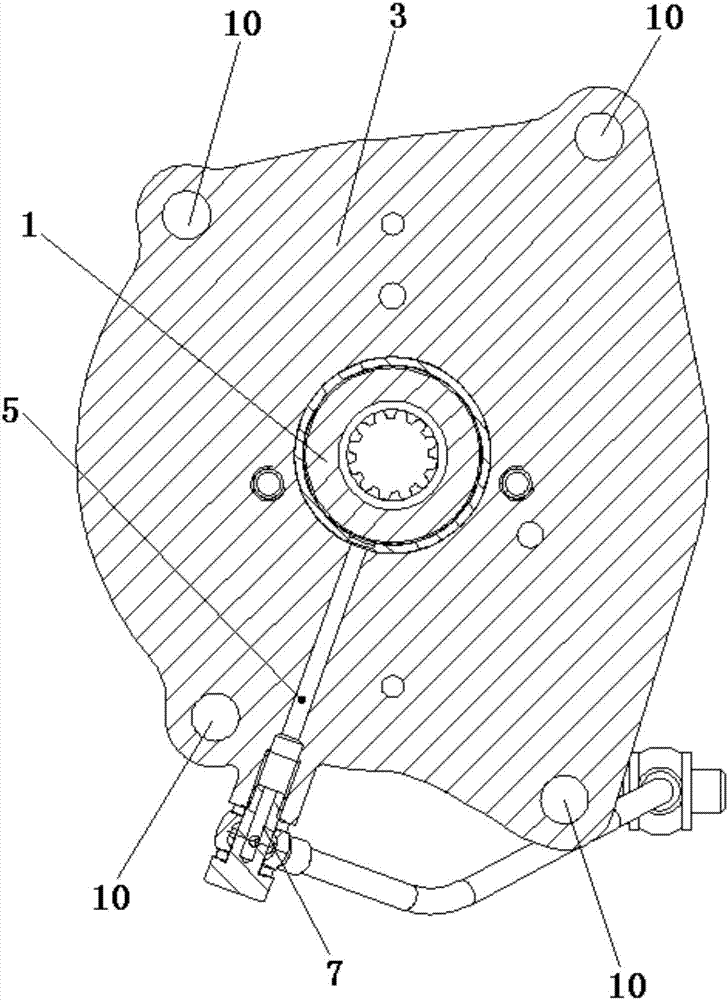

[0028] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

[0029] refer to Figure 1-5 , a power output device of a non-road diesel engine of the present invention includes a gear shaft 1 that can be connected with the rear gear train of the engine. The end of the shaft 1 far away from the gear train is provided with a thrust plate 2, which is used to prevent the gear shaft 1 from axially shifting, and the gear shaft 1 between the thrust plate 2 and the gear train is provided with a movable The shaft seat 3 connected with the engine gear chamber, the shaft seat 3 is used to support the gear shaft 1, and a bushing 4 is embedded between the gear shaft 1 and the shaft seat 3, and the bushing 4 is made of high wear-resistant material It is made to prevent the relative friction between the gear shaft 1 and the shaft seat 3 from being damaged; the shaft seat 3 is provided with an oil inlet passage 5 open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com