Modular partition wall and assembling method thereof

A modular and modular technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of cumbersome construction of prefabricated partition walls and unsatisfactory lateral load-bearing performance of joints, so as to improve the convenience of construction and improve the overall Accuracy, the effect of reducing the number of times to modify the panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

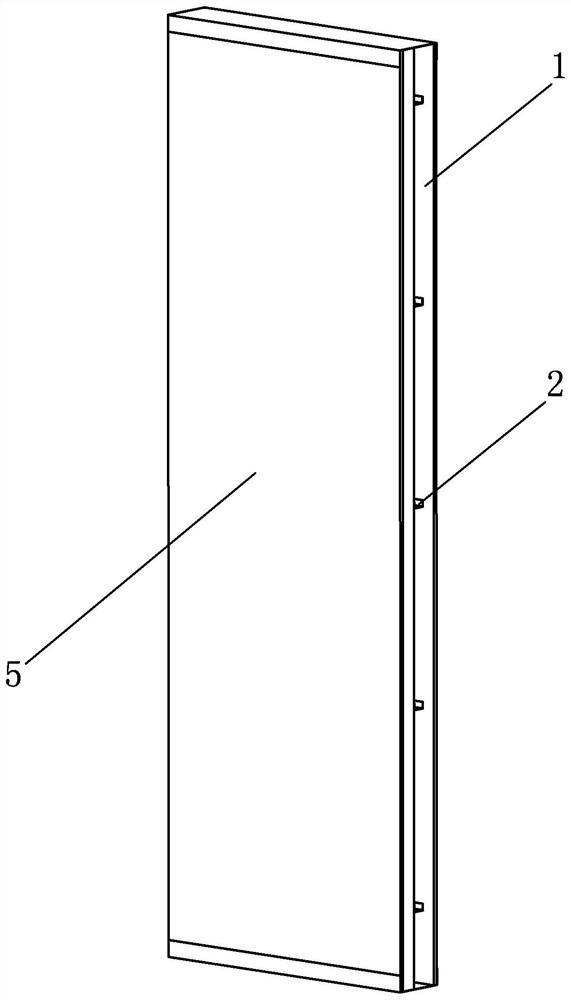

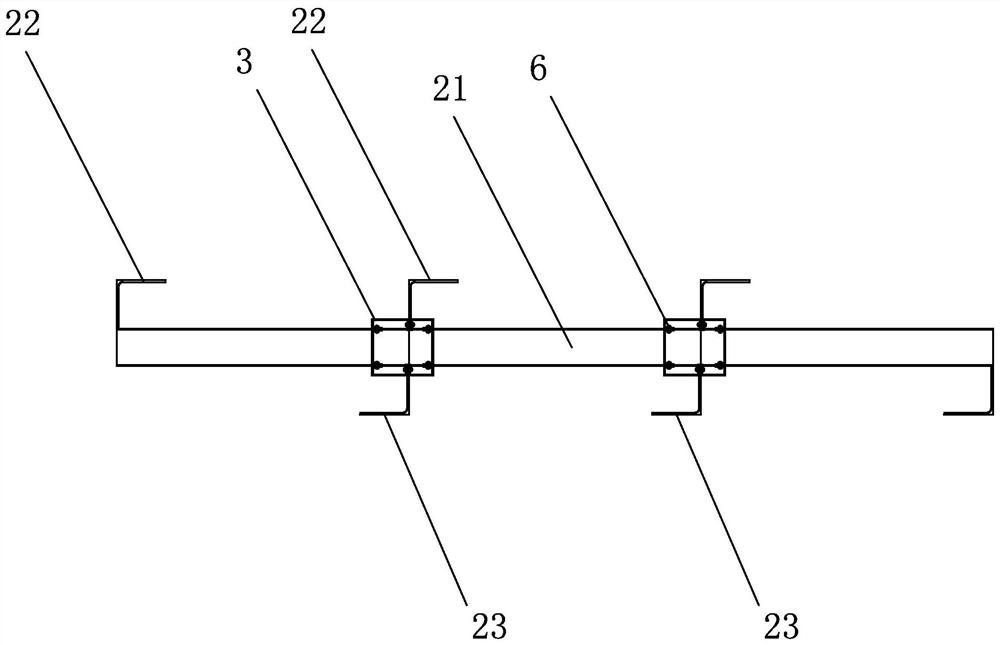

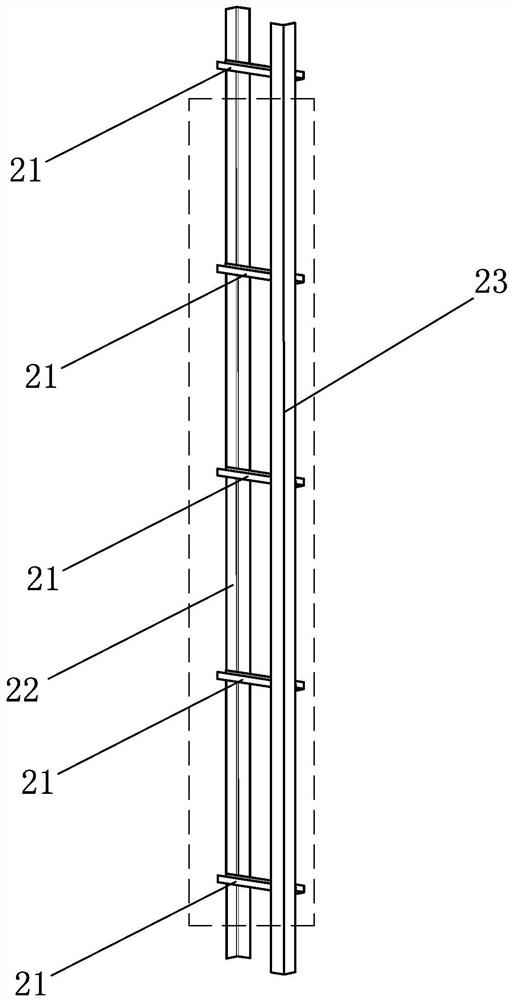

[0036] Such as figure 1 , as shown in 2 and 5, a modular partition wall includes a modular partition wall assembly 1, which is used to realize fast assembly and is a modular partition wall assembly; the modular partition wall assembly 1 includes a sandwich skeleton 2; Misalignment plug-in 3 is used to realize the synchronous splicing and insertion of modular partition wall components in the horizontal and vertical directions to form a general-purpose component of modular partition wall; The connecting groove 4; wherein, the side of the sandwich frame is installed with a veneer 5. The modular partition wall disclosed in the present invention is assembled and formed through the end-to-end connection of several modular partition wall components, and the sandwich skeleton is the keel structure in the modular partition wall component, which plays a main supporting role. Dislocation splicing plugs are used to splice and connect the sandwich skeletons of adjacent modular partition w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com