Method for machining thin-wall sleeve type part through wedge type inner supporting mechanism

A technology of inner support mechanism and sleeve, which is applied in the field of machining, can solve the problems of large machining deformation, clamping deformation, and tool clearance, etc., and achieve the effect of solving large processing deformation, reducing clamping deformation, and avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiment of the present application provides a method for processing thin-walled sleeve parts by using a wedge-type internal support mechanism, which solves or partially solves the problem of large deformation of the parts in the prior art, chatter marks on the surface of the parts after processing, and problems in clamping. The deformation leads to the technical problem that the follow-up finishing size is difficult to control, and the vibration, tool gap, uneven wall thickness, deformation and other phenomena existing in turning the outer circle have been avoided, and the qualified rate of parts has increased from 70% to more than 97%.

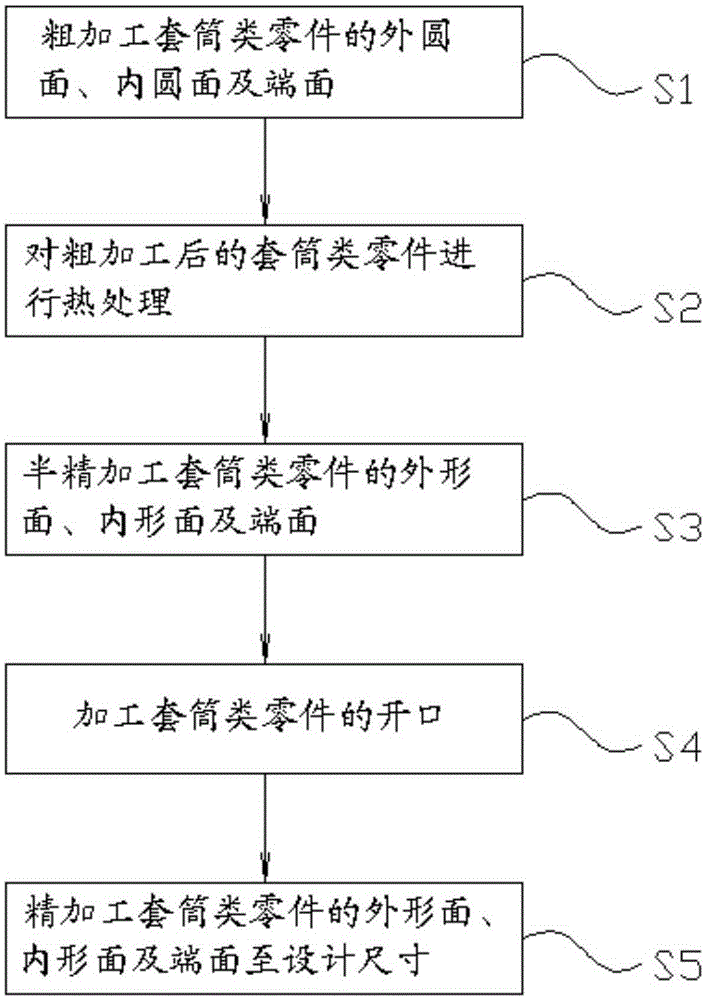

[0036] See attached figure 1 , a method for processing thin-walled sleeve parts using a wedge-type internal support mechanism provided in an embodiment of the present application includes the following steps:

[0037] S1: Rough machining the outer circular surface, inner circular surface and end surface of the sleeve part 1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com