Indexing jig device for radial hole in cylindrical face

A technology of radial holes and cylindrical surfaces, which is applied in the field of radial hole indexing drilling devices on cylindrical surfaces, can solve problems such as not being suitable for mass production and fracture, and achieve improved labor productivity, reduced loss, and small clamping deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

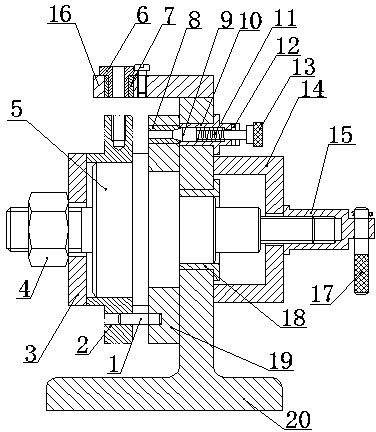

[0009] like figure 1 It is a structural schematic diagram of the present invention, a radial hole indexing drilling device on a cylindrical surface, including a clamp body 20 and a workpiece 2, and the clamp body 20 is provided with a locking bracket 14 and a mandrel bushing 18. The mandrel bushing 18 is provided with a positioning mandrel 5, the positioning mandrel 5 is provided with an opening pressure plate 3 and a rotary index plate 19, the clamp body 20 is provided with a drill sleeve frame 16, and the workpiece 2 and A workpiece positioning pin 1 is arranged between the rotary indexing discs 19, a bushing 7 is arranged on the drill bushing frame 16, a drill bushing 6 is arranged inside the bushing 7, and a spring seat is arranged on the clamp body 20 10. The spring seat 10 is provided with a compression spring 11, an indexing plate positioning pin 9 and a handle 13, and the spring seat 10 is provided with a horizontal pin 12, and the upper part of the rotary indexing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com