Vacuum adsorption clamp and adsorption method for clamping thin-wall spherical shell type micro component

A technology of vacuum adsorption and vacuum suction head, which is applied in the direction of clamping, positioning devices, clamping devices, etc., can solve the problems of low repeat positioning accuracy, complex control parts, and large deformation of the spherical shell, so as to facilitate the secondary accurate tool setting , Guaranteed processing accuracy and small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] combined with Figure 1-9 , the realization of the present invention is described as follows:

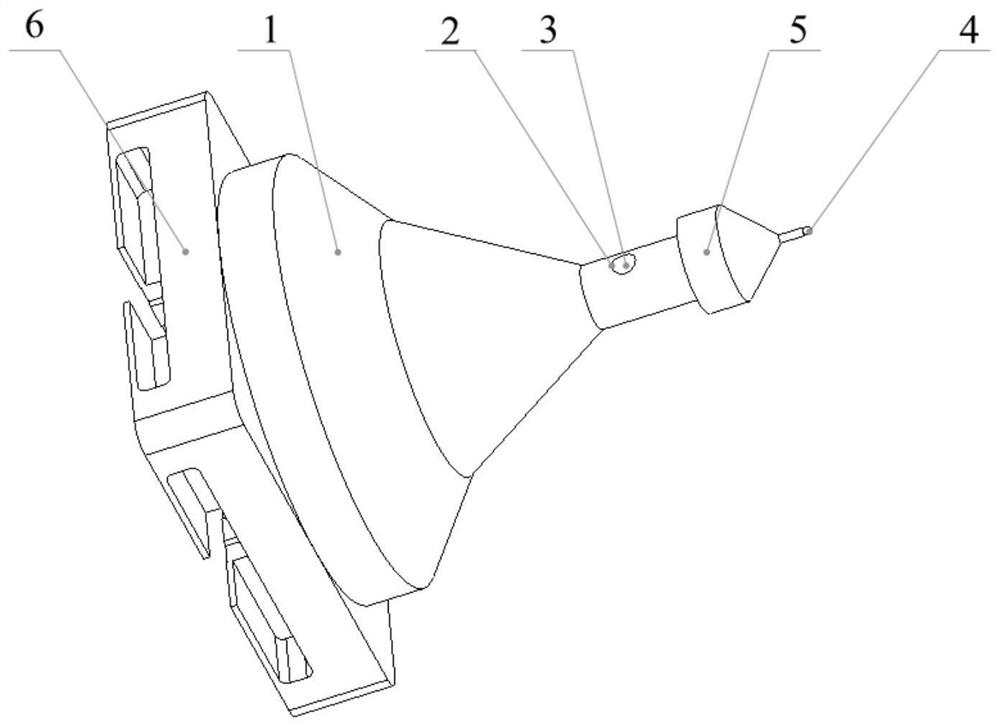

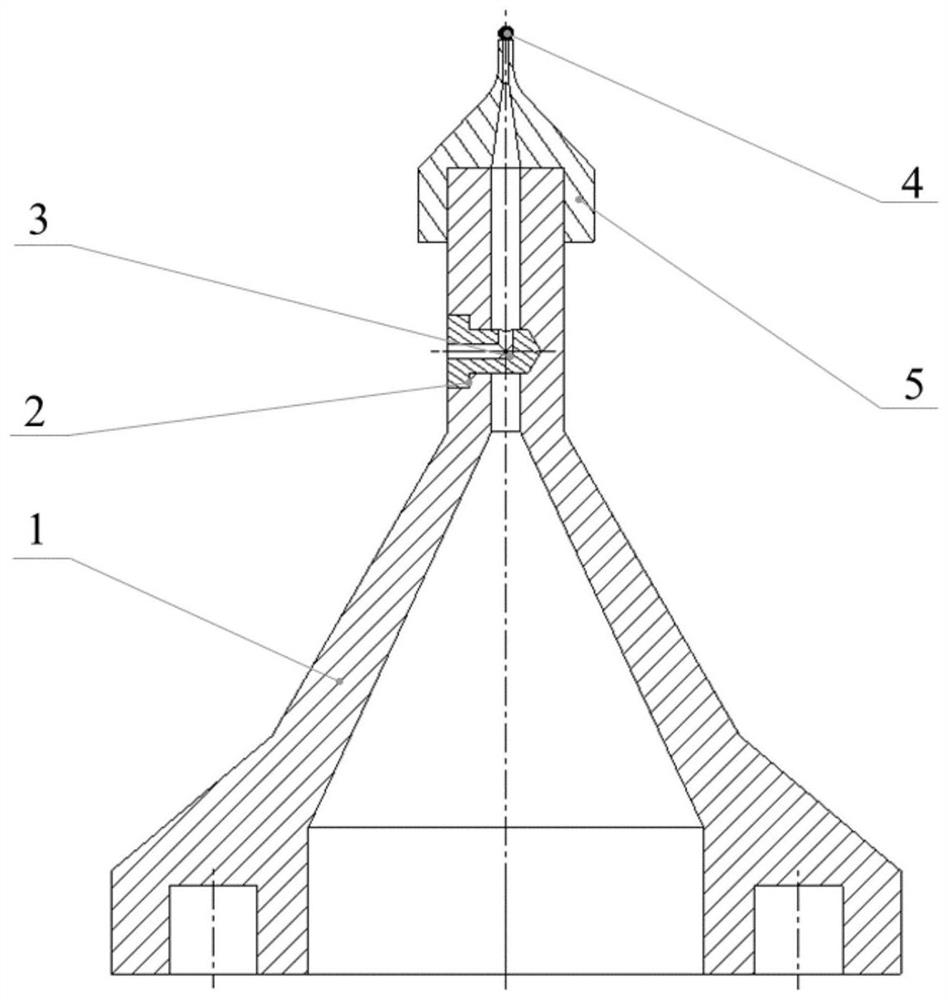

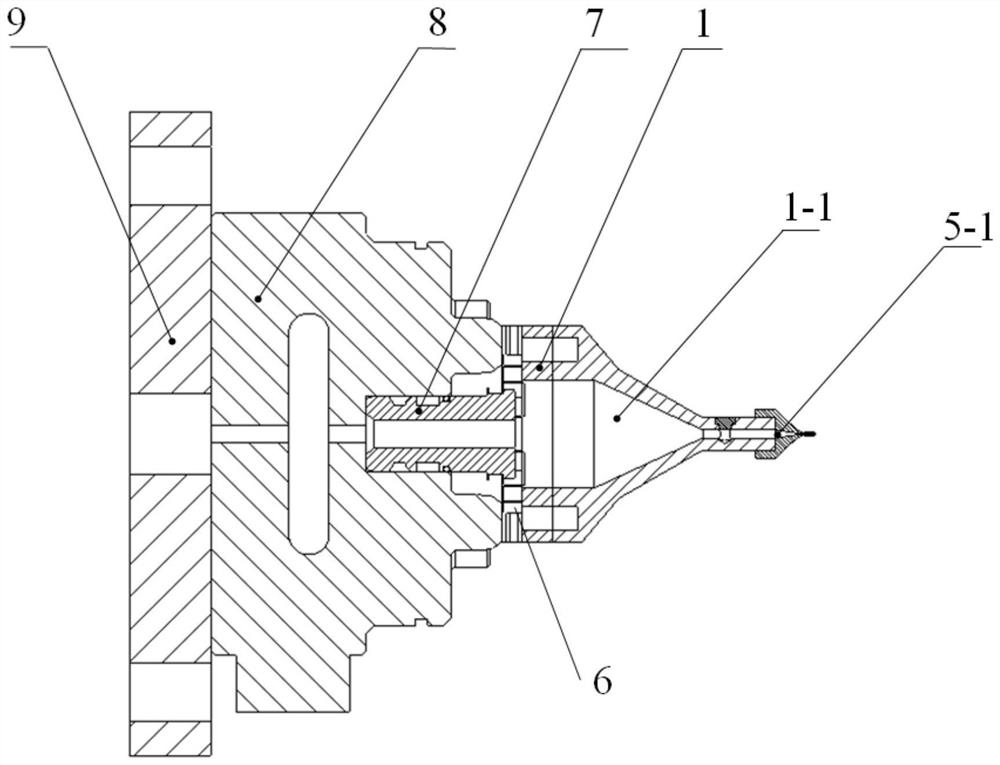

[0058] Such as Figure 1-6 As shown, the vacuum adsorption fixture used for clamping thin-walled spherical shell micro components according to the present invention includes a vacuum adsorption fixture main body 1 and a vacuum suction head 5. 5 is sealed and detachably connected to the adsorption end of the vacuum adsorption fixture main body 1, the connection end of the vacuum adsorption fixture main body 1 is used to connect with the reference piece of the zero point positioning quick change device, and the end of the vacuum suction head 5 is used to absorb the tiny thin-walled spherical shell 4; The vacuum cavity 1-1 on the main body of the vacuum adsorption fixture along its axial direction becomes smaller along the connecting end to the adsorption end; the vacuum cavity 1-1 is used as the main air source channel, and the main body of the vacuum adsorption fixture 1 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com