Control method of grinding distortion of outer diameter of guide barrel of auto bank unit of helicopter

An automatic tilter and control method technology, applied in the mechanical field, can solve the problems of low product qualification rate and easy deformation, and achieve the effects of increasing the contact area, reducing the clamping deformation, improving the processing accuracy and the product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] Describe in detail below in conjunction with specific embodiment the control method of the grinding deformation of the guide cylinder outer diameter of the helicopter automatic tilter of the present invention as follows:

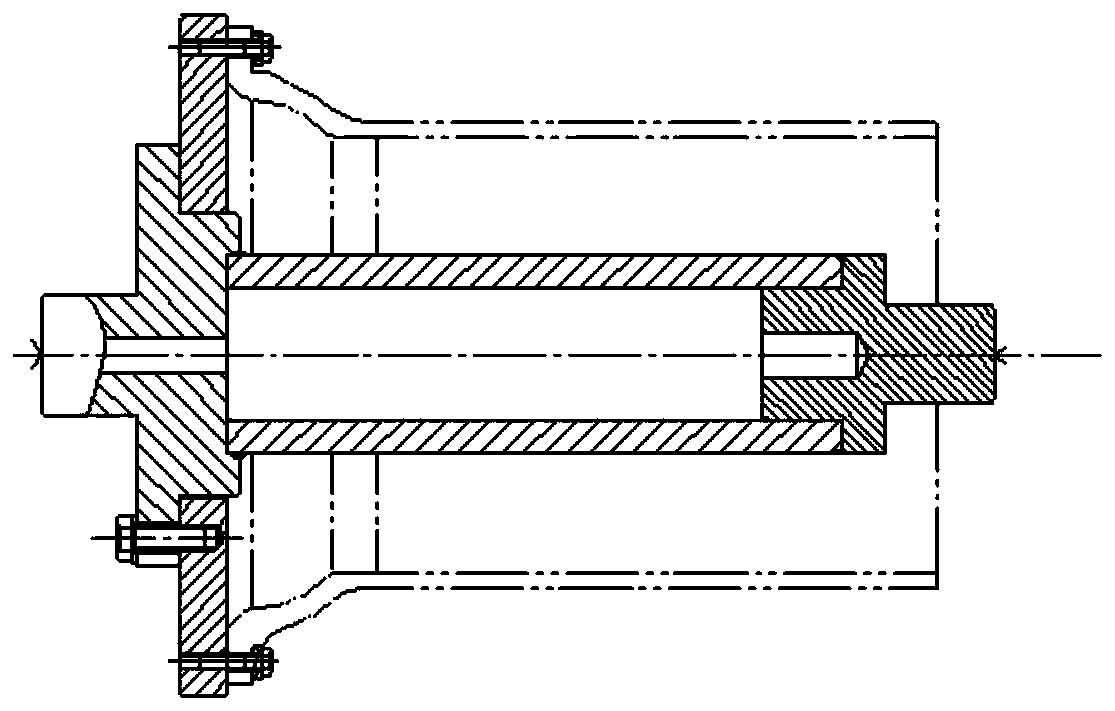

[0023] The control technique for the grinding deformation of the outer diameter of the guide cylinder of the helicopter automatic tilter is to measure the deformation high and low point areas of the rough machined surface of the part, and manually repair the high point area and the transition area corresponding to the positioning surface of the part; The clamping force of the tightening bolt on the positioning hole of the machine is used to improve the clamping deformation of the part; and a method of improving the grinding deformation by using a special grinding method.

[0024] Such as figure 1 The schematic diagram of the combined assembly of the helicopter automatic tilter guide cylinder and the fixture is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com