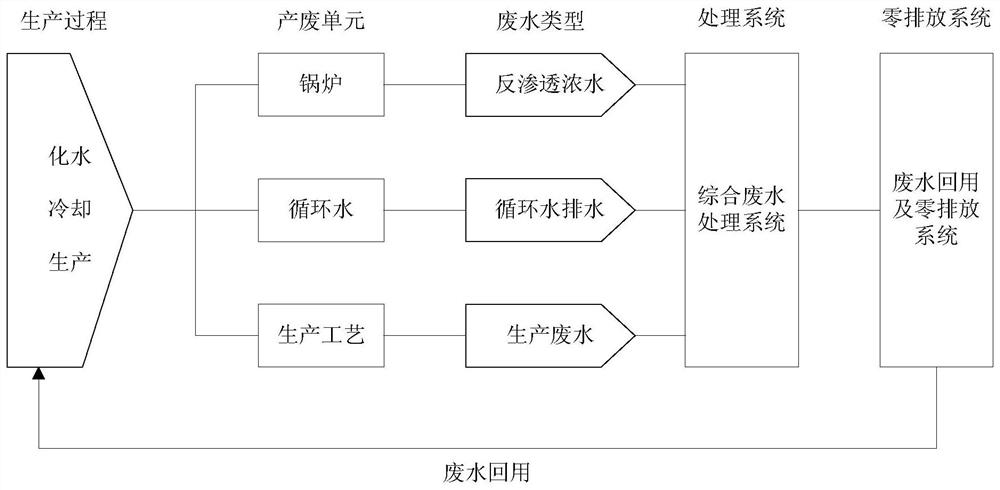

A zero-discharge process route for enterprise production wastewater based on the 3r principle

A technology for the production of wastewater and process routes, applied in the field of water treatment, can solve the problems of high investment and cost, high risk of zero-discharge process route of combined wastewater, etc., and achieve the effect of reducing wastewater discharge, significant technical and economic advantages, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

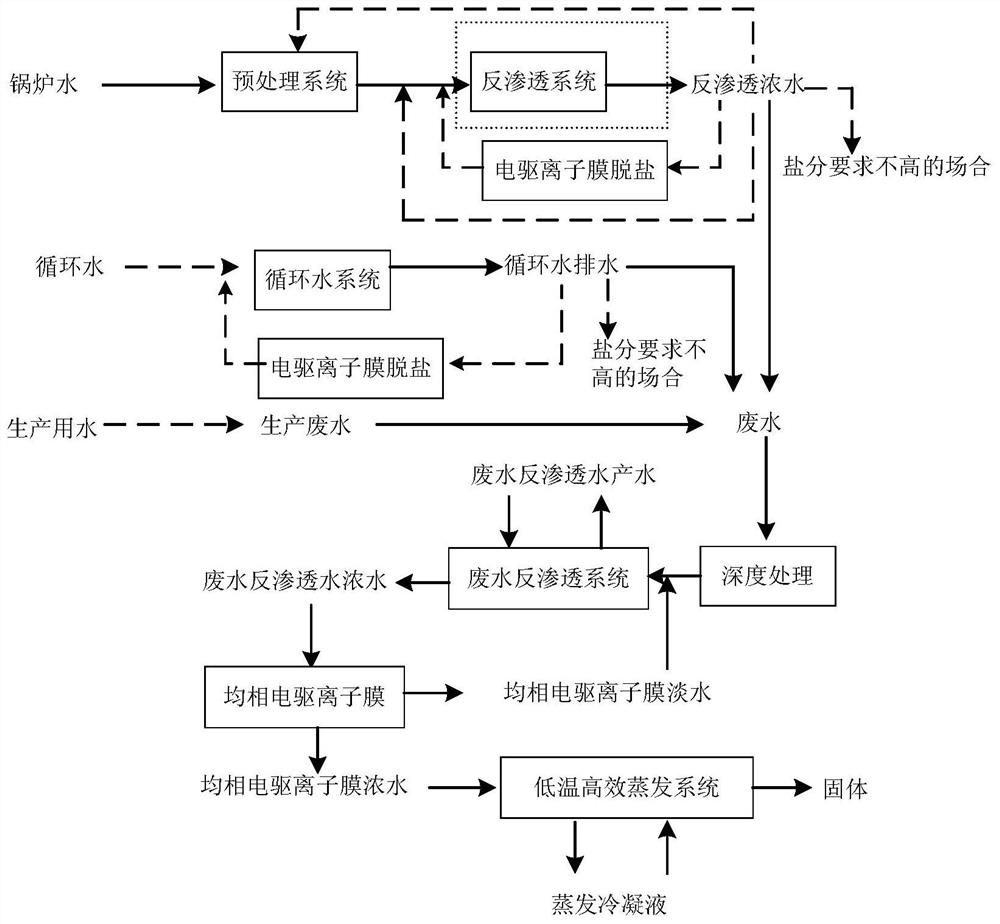

[0060] A zero-discharge process route for enterprise production wastewater based on the 3R principle. The schematic diagram of the process route is shown in figure 2 ,Specific steps are as follows:

[0061] Step 1: Wastewater source reduction

[0062] (1) Reduction measures for reverse osmosis concentrated water:

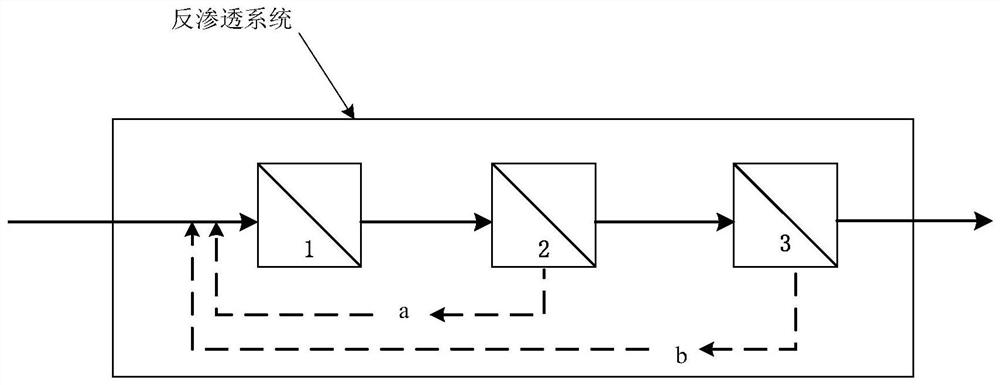

[0063] ①Using reverse osmosis concentrated water to backwash the pretreatment filter in the pretreatment, and reduce the frequency of backwashing to 24 hours / time, reduce the consumption of backwashing water, and save water by 5%;

[0064] ② Under the condition of ensuring the water quality of the produced water, return 10% of the reverse osmosis concentrated water to the water inlet of the reverse osmosis system for circulation treatment, and at the same time, the operating pressure of the reverse osmosis is increased by 10%, the water yield is increased by 10%, and the water is saved by 10%;

[0065] During this process, the reverse osmosis concentrated water d...

Embodiment 2

[0081] A zero-discharge process route for enterprise production wastewater based on the 3R principle. The schematic diagram of the process route is shown in figure 2 ,Specific steps are as follows:

[0082] Step 1: Wastewater source reduction

[0083] (1) Reduction measures for reverse osmosis concentrated water:

[0084] ①Using reverse osmosis concentrated water to backwash the pretreatment filter in the pretreatment, and reduce the frequency of backwashing to 48 hours / time, reduce the consumption of backwashing water, and save water by 10%;

[0085] ② Under the condition of ensuring the water quality of the produced water, 5% of the reverse osmosis concentrated water is returned to the water inlet of the reverse osmosis system for circulation treatment, and at the same time, the operating pressure of the reverse osmosis is increased by 5%, the water yield is increased by 5%, and the water is saved by 5%;

[0086] ③In the two-stage reverse osmosis-electric desalination ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com