Treatment process device and method for resin-adsorbed regenerated high-concentration organic waste liquid

A technology of organic waste liquid and resin adsorption, applied in adsorption water/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc. The lack of treatment process equipment for waste liquid achieves the effect of simple operation and management, low operation cost and huge technical and economic advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

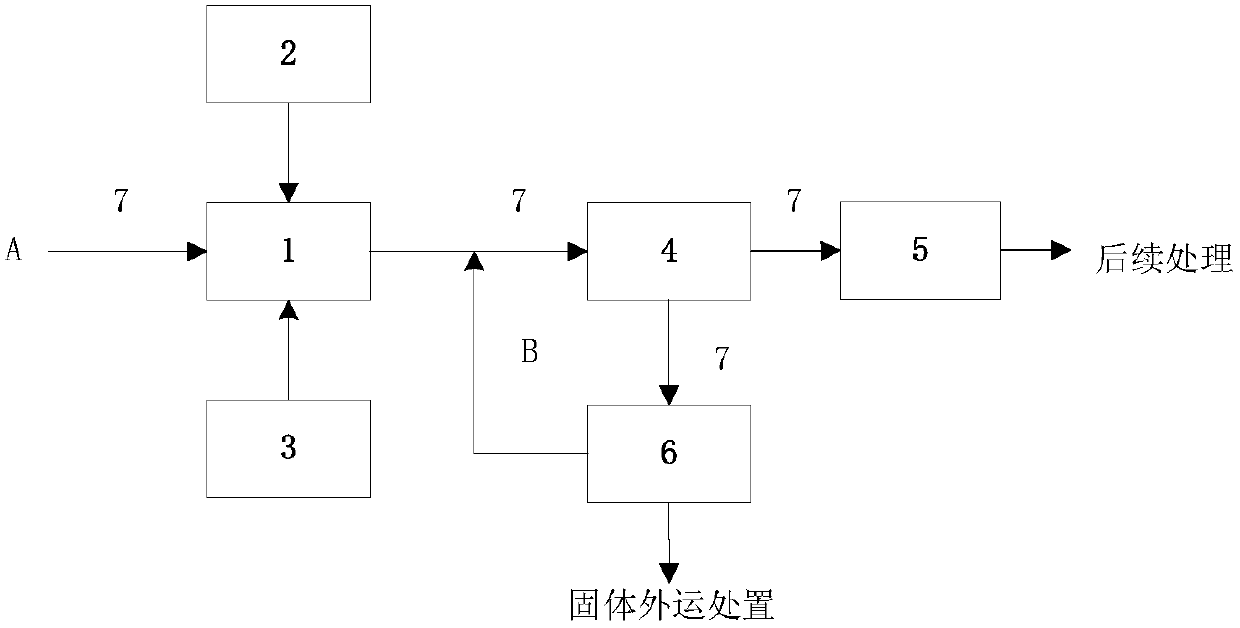

[0042] A treatment process device for resin adsorption and regeneration of high-concentration organic waste liquid, the flow chart of the device is shown in figure 1 , the process device includes catalytic coagulation reaction equipment, mud-water separation and concentration equipment 4, adsorption equipment 5 and solid dehydration equipment 6;

[0043] The catalytic coagulation reaction equipment, the mud-water separation and concentration equipment 4 and the adsorption equipment 5 are connected with pipelines in turn, the mud-water separation and concentration equipment 4 is bypassed with a solid dehydration equipment 6, the outlet of the mud-water separation and concentration equipment 4 and the solid dehydration equipment 6 inlet Connection, the solid dehydration equipment 6 is provided with a solid outlet and a liquid outlet, and the liquid outlet is connected to the inlet of the mud-water separation and concentration equipment 4 .

[0044] The catalytic coagulation reac...

Embodiment 2

[0064] A treatment process device for resin adsorption and regeneration of high-concentration organic waste liquid, the same as in Example 1.

[0065] A processing method for resin adsorption and regeneration of high-concentration organic waste liquid, comprising the following steps:

[0066] Step 1, Catalysis - Condensation

[0067] The high-concentration organic waste liquid A is pumped into the catalytic coagulation reactor 1 by the pump 7 for adsorption and regeneration of the resin, and the catalyst is added to the catalyst preparation and dosing equipment 2, and the jet stirring equipment 3 is used for mechanical stirring. The mixing time is 5 minutes, and the resin is adsorbed and regenerated The organic matter in the high-concentration organic waste liquid undergoes a coagulation reaction under the action of a catalyst. The reaction time is 15 minutes. Catalyst that causes organic matter to undergo condensation reaction to form a precipitate. The amount of catalyst ad...

Embodiment 3

[0080] A treatment process device for resin adsorption and regeneration of high-concentration organic waste liquid, the same as in Example 1.

[0081] A processing method for resin adsorption and regeneration of high-concentration organic waste liquid, comprising the following steps:

[0082] Step 1, Catalysis - Condensation

[0083] The high-concentration organic waste liquid A is pumped into the catalytic coagulation reactor 1 by the pump 7 for resin adsorption and regeneration, and the catalyst is added by the catalyst preparation and dosing device 2, and the jet stirring device 3 is used for mechanical stirring. The stirring and mixing time is 3 minutes, and the resin is adsorbed and regenerated The organic matter in the high-concentration organic waste liquid undergoes a coagulation reaction under the action of a catalyst, and the reaction time is 10 minutes. Catalyst that causes organic matter to undergo condensation reaction to form a precipitate. The amount of catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com