Method for improving wettability of Al2O3 porous perform and NbAl molten alloy

A prefabricated and wettable technology, applied in the field of improving wettability in the process of pressureless infiltration of NbAl/Al2O3 composite materials, can solve the problems of inability to achieve effective pressureless infiltration, poor wettability, etc., to extend the range of use, improve Wetting properties, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] (a) After the NbAl intermetallic compound is crushed into fine particles, the model is ball milled for 24 hours by QM-3SP2 ball mill to obtain a fine powder with a particle size of about 100 microns;

[0012] (b) NbAl powder and Ti powder are batched and mixed uniformly according to the atomic percentages of Nb, Al and Ti being 45%, 20%, and 35% respectively by a mixer;

[0013] (c) Using a tablet press of model 769YP-24B to compress the above-mentioned mixed powder into a disc shape;

[0014] (d) Place the disc-shaped pressed part on the bottom or top of the alumina preform, and put it into an electromagnetic induction furnace for pressureless infiltration. The infiltration temperature is 1830°C and the vacuum degree is 2×10 -3 Pa;

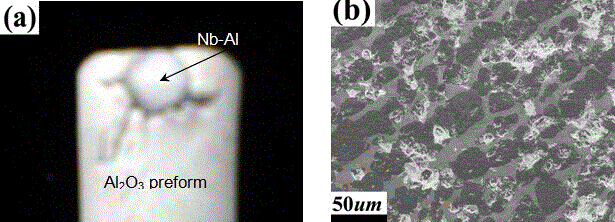

[0015] Scanning electron microscope morphology observation and energy spectrum analysis show that the alloy melt completely fills the whole skeleton of the alumina preform, realizing pressureless infiltration.

Embodiment 2

[0017] (a) After the NbAl intermetallic compound is broken into fine particles, the model is QM-3SP2 ball mill ball milled for 24 hours to obtain a fine powder with a particle size of about 100 microns;

[0018] (b) NbAl powder and Ti powder are batched and mixed uniformly according to the atomic percentages of Nb, Al and Ti being 55%, 35%, and 10%, respectively, using a mixer;

[0019] (c) Using a tablet press of model 769YP-24B to compress the above-mentioned mixed powder into a disc shape;

[0020] (d) Place the disc-shaped pressed part on the bottom or top of the alumina preform, and put it into an electromagnetic induction furnace for pressureless infiltration. The infiltration temperature is 1860 °C and the vacuum degree is 2×10 -3 Pa;

[0021] Scanning electron microscope morphology observation and energy spectrum analysis show that the alloy melt completely fills the whole skeleton of the alumina preform, realizing pressureless infiltration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com