Thermal mass decoupling heat exchanger and thermal mass decoupling method thereof

A heat exchange technology for heat exchangers and heat pipes, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as reduced efficiency, reduced system economy, and difficulty in practical promotion and application, to achieve efficient heat exchange and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

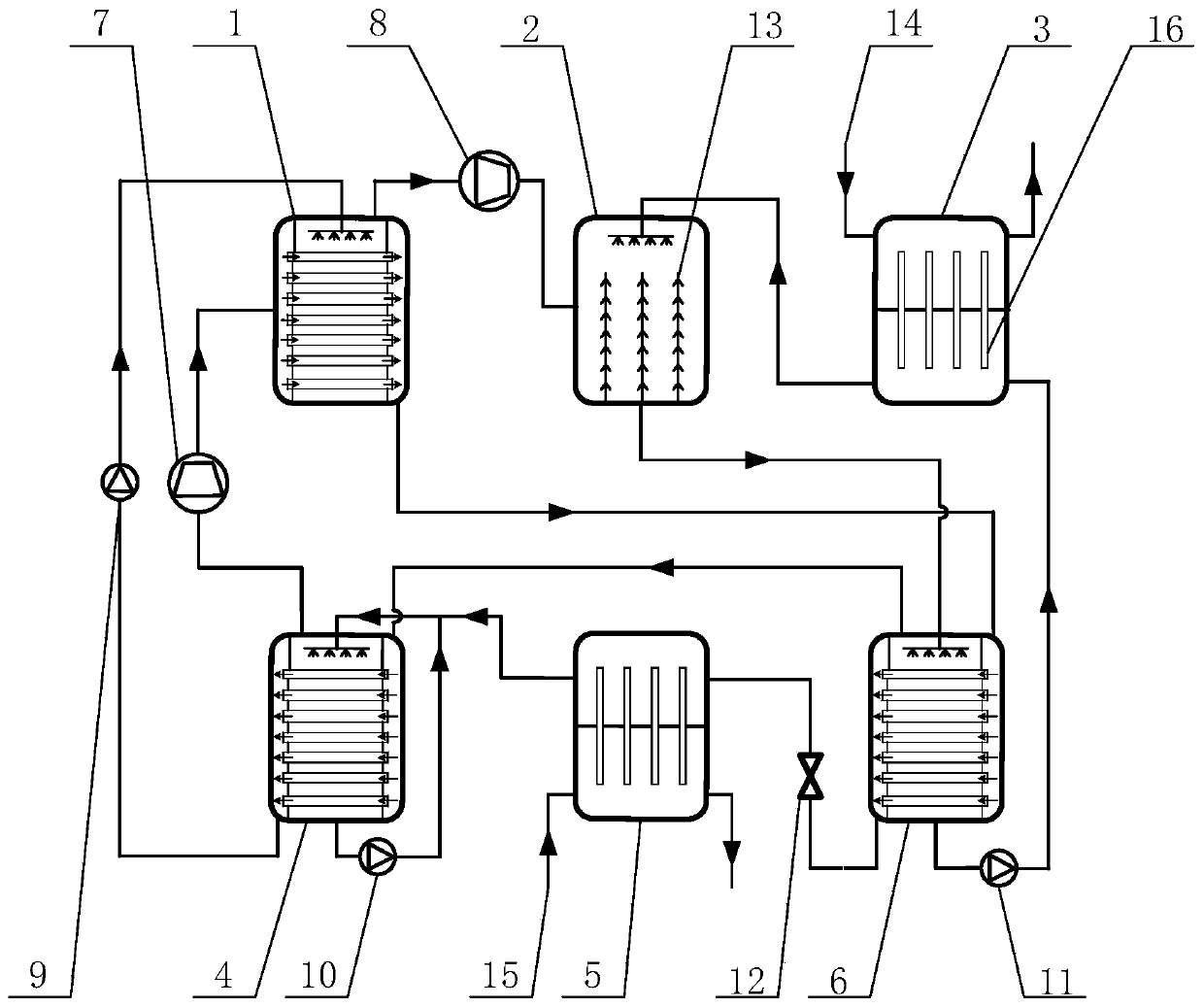

[0023] The internal circulating medium of the thermal mass decoupling heat exchanger is composed of working medium A, working medium B and working medium C, wherein the internal circulating medium, working medium A selects R32, working medium B selects R134a and working medium C selects R125, Among them, R32 and R134a constitute a working pair. The heat transfer process and mass transfer process of R32 and R134a are decoupled inside the heat exchanger, and the heat transfer process is carried out in the phase change heat exchanger 1 and the mass transfer process is carried out in the absorption tower 2 by operating independently. The first phase change heat exchanger 1 realizes the evaporation process of R134a and the condensation process of R125 in the space outside the heat transfer tube; the second phase change heat exchanger 4 realizes the evaporation process of R125 in the space outside the heat transfer tube and The condensation process of the space R134a in the heat tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com