Vertical helix ditching machine spiral cutter combination

A ditching machine and spiral technology, applied in the field of vertical spiral ditching machine and spiral cutter combination, can solve the problems of ditching effect influence, ditching machine is easy to be damaged, and work efficiency is low, so as to improve the level of agricultural mechanization and facilitate installation , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

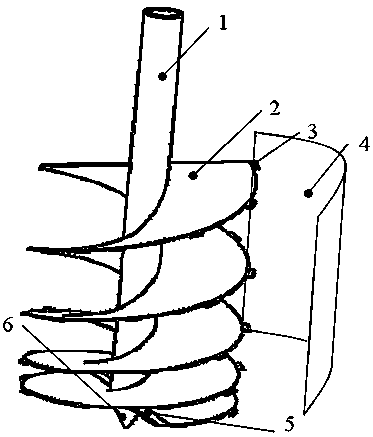

[0015] figure 1 The spiral cutter combination of the neutral spiral trencher is mainly composed of a main shaft, a helical blade, a helical soil cutting blade, a baffle plate, an end surface cutting blade, a drill tip, etc.; The blade drives the helical blade to carry out soil milling movement. The main shaft is designed as a hollow shaft, and the seamless steel pipe is used to reduce the weight of the tool. The most important part of the tool structure, its structural performance directly affects the power consumption of cutting soil and the performance of soil lifting and throwing. The helical blades are actually two variable pitch helical surfaces, which are composed of variable pitch The spiral blade is welded on the outer edge of the spiral blade, which reduces the wear of the spiral blade; the end face soil cutting blade is fixed on the knife seat welded to the end of the spiral blade through bolt connection , the thickness of both the blade and the tool seat is 3mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com