Electric four-wheel mower blade brake mechanism

A brake mechanism and lawn mower technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as low assembly efficiency, complex structure, and poor reliability, and achieve high work efficiency, reasonable layout, and low production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

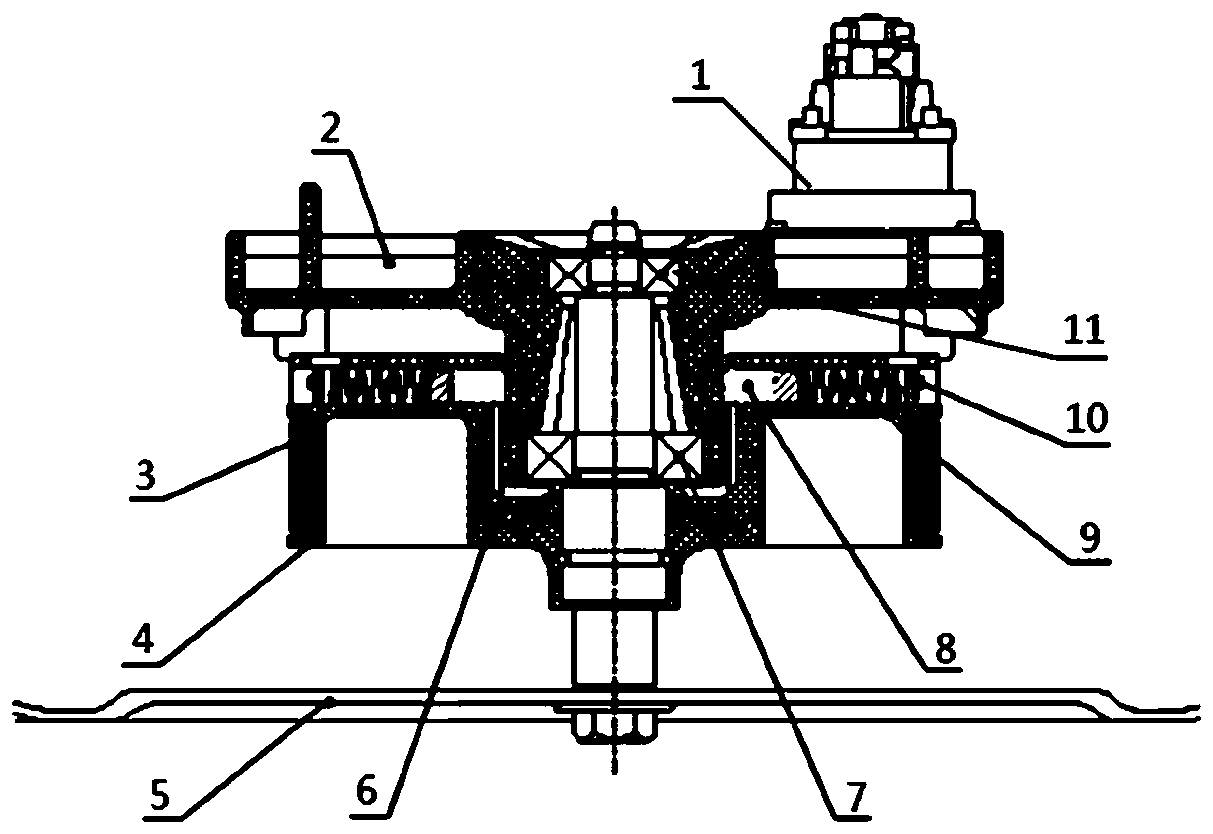

[0014] figure 1 The blade brake mechanism of the medium electric four-wheel lawn mower is mainly composed of a series motor, a support, a V-ribbed belt, a cutting blade, a large pulley, a brake ring, a bearing I, a brake pad, a brake spring, a retainer, The brake mechanism mainly realizes the brake function through the friction between the brake pad and the brake ring, and the braking time is controlled within 3s; the series excitation motor is fixed at one end of the support; the The large pulley is fixed on the other end of the support through bearing I and bearing II; the brake ring is also fixed on one end of the support (that is, the same end as the large pulley); the series excitation motor is driven by a V-ribbed belt The large pulley rotates, thereby driving the blades to rotate to realize the mowing function; the brake pad contacts the brake ring under the pressure of the brake spring; the brake pad is made of a composite of friction material and metal iron block bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com