Painting color palette machining device

An art palette and processing device technology, applied in painting tools, decorative arts, manufacturing tools, etc., can solve the problems of low level of mechanization, low production efficiency, and high labor costs, and achieve high level of mechanization, cost savings, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

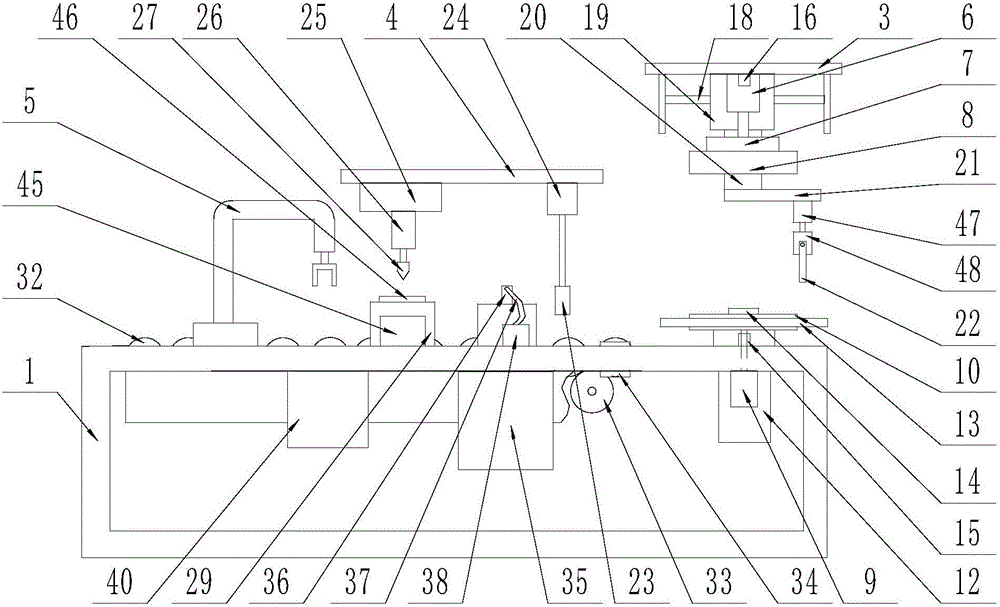

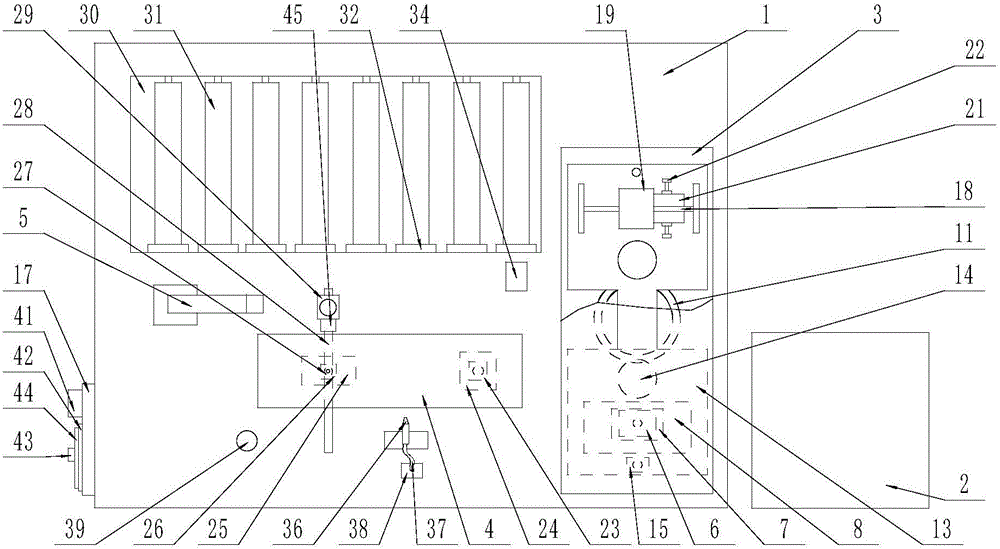

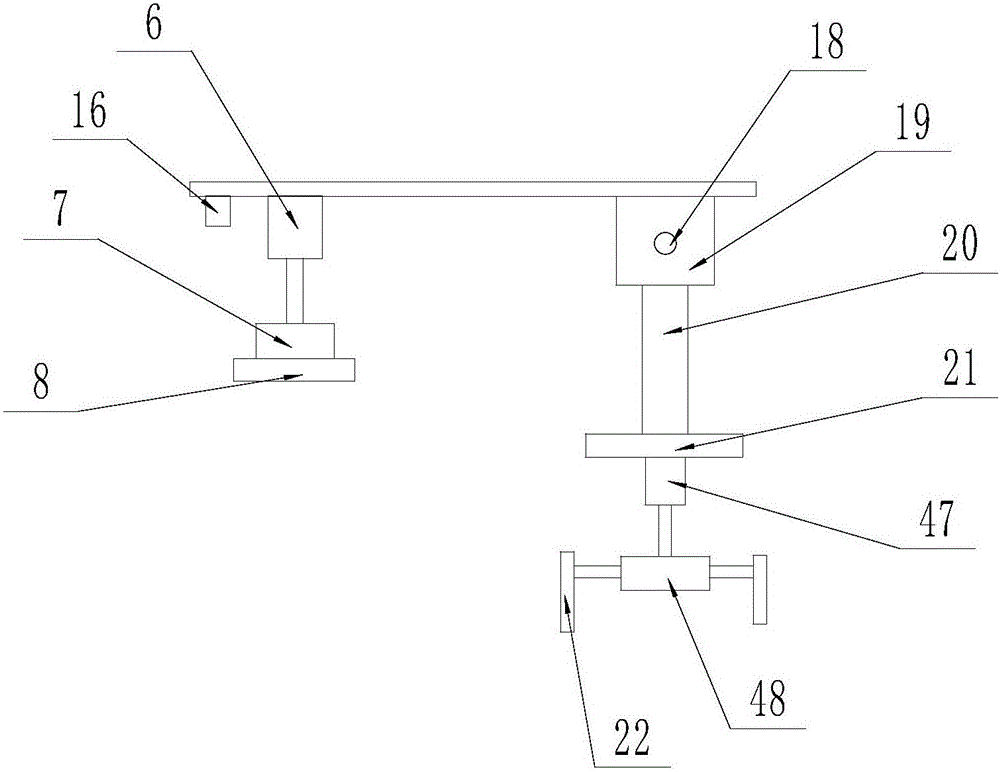

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a kind of art palette processing device comprises a workbench (1) and a conveying platform (2) arranged on one side of the workbench (1) for conveying plates, and the inside of the workbench (1) is empty cavity structure, the workbench (1) is provided with a mounting plate (3) above one end close to the conveying platform (2), and a cutting unit and a carving unit are provided on the mounting plate (3), and the workbench (1) A support (4) is provided above, and a stamping unit and a milling unit are sequentially provided on the support (4), and a manipulator (5) for transferring plates is provided on the workbench (1), and the workbench (1) ) is provided with a delivery unit at the rear end of the upper surface, and the worktable (1) is provided with a double-station carrying mechanism, and the double-station carrying mechanism is formed by a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com