Inner section removal machine for bamboo

A technology for removing inner knots and bamboos, which is applied in mechanical equipment, sugarcane machining, irregular removal devices, etc., can solve the problems of difficulty in ensuring the processing quality of inner knots and low labor efficiency in removing inner knots, so as to improve efficiency and expand Quality assurance, the effect of improving the level of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

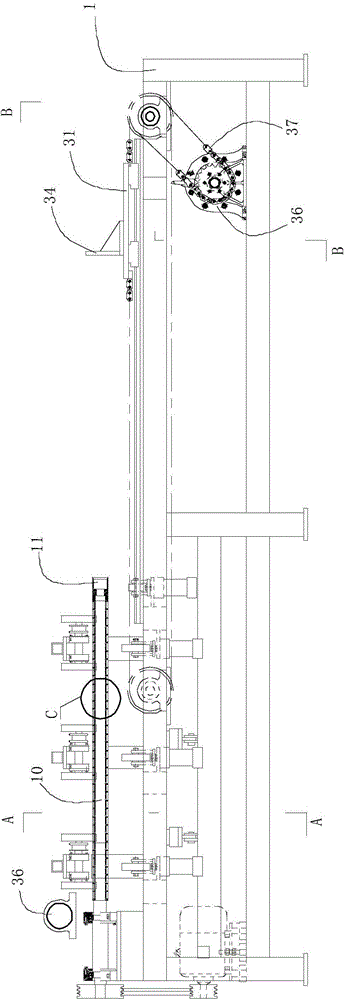

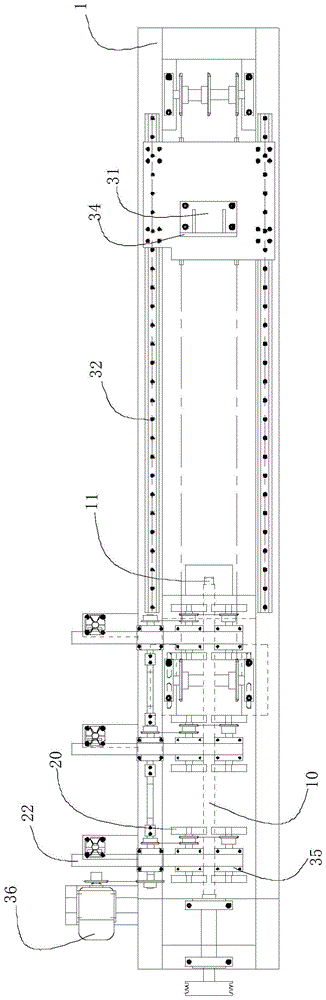

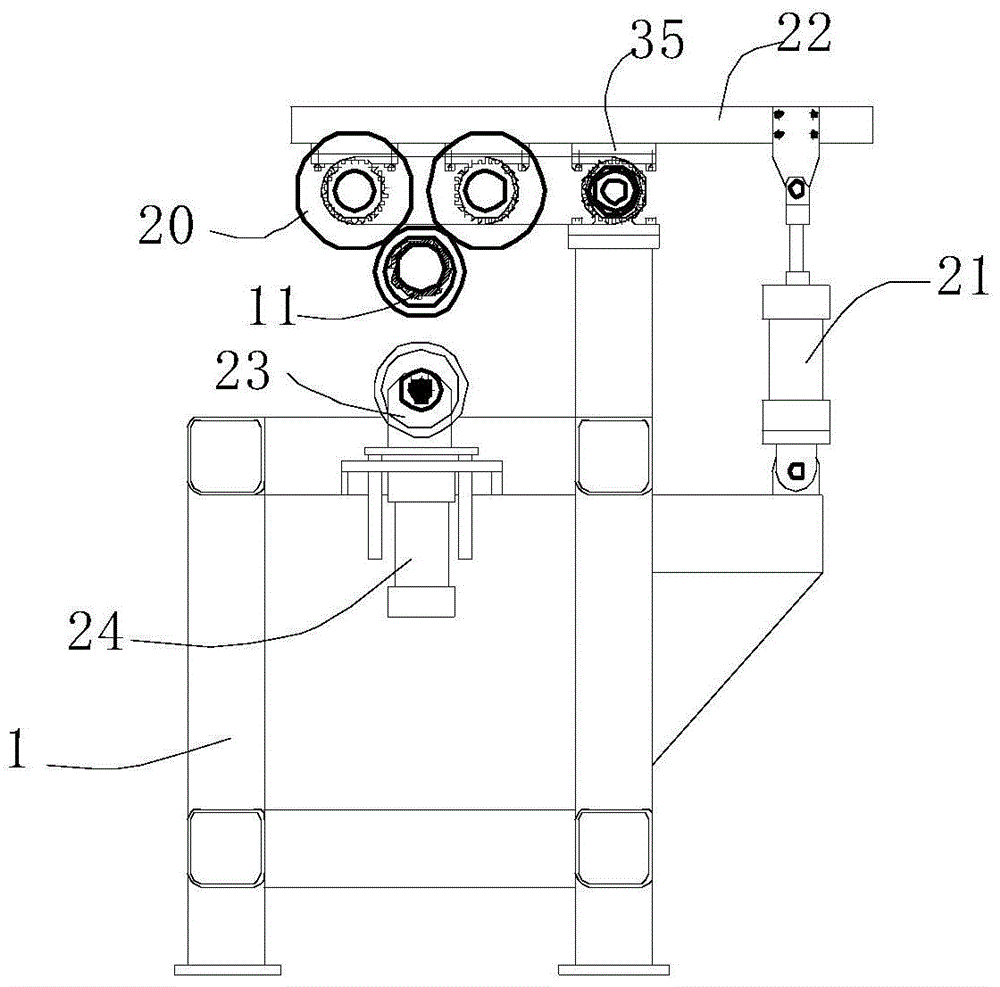

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown bamboo inner section machine includes a frame 1, an inner section cutter assembly, a bamboo axial propulsion mechanism for pushing bamboo into the inner section cutter assembly along its length direction and a bamboo radial positioning bamboo Radial positioning mechanism. The internal segment removal tool assembly is fixedly installed on the frame 1, the bamboo axial propulsion mechanism corresponds to the internal segment removal tool assembly, and the bamboo radial positioning mechanism is located on the outer periphery of the internal segment removal tool assembly.

[0022] The inner segment cutter assembly includes a cutter shaft 10 driven by the main motor, a punching knife 11 arranged at the front end of the cutter shaft 10, a plurality of scrapers 12 for grinding the inner segments of bamboo, and a plurality of positioning rings 13 to prevent excessive grinding, A plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com