Small combine harvester for rice

A technology of combine harvester and rice, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of low level of rice production mechanization, long harvesting process time, labor and labor loss, etc., and achieves the improvement of agricultural mechanization level. , Simple structure, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

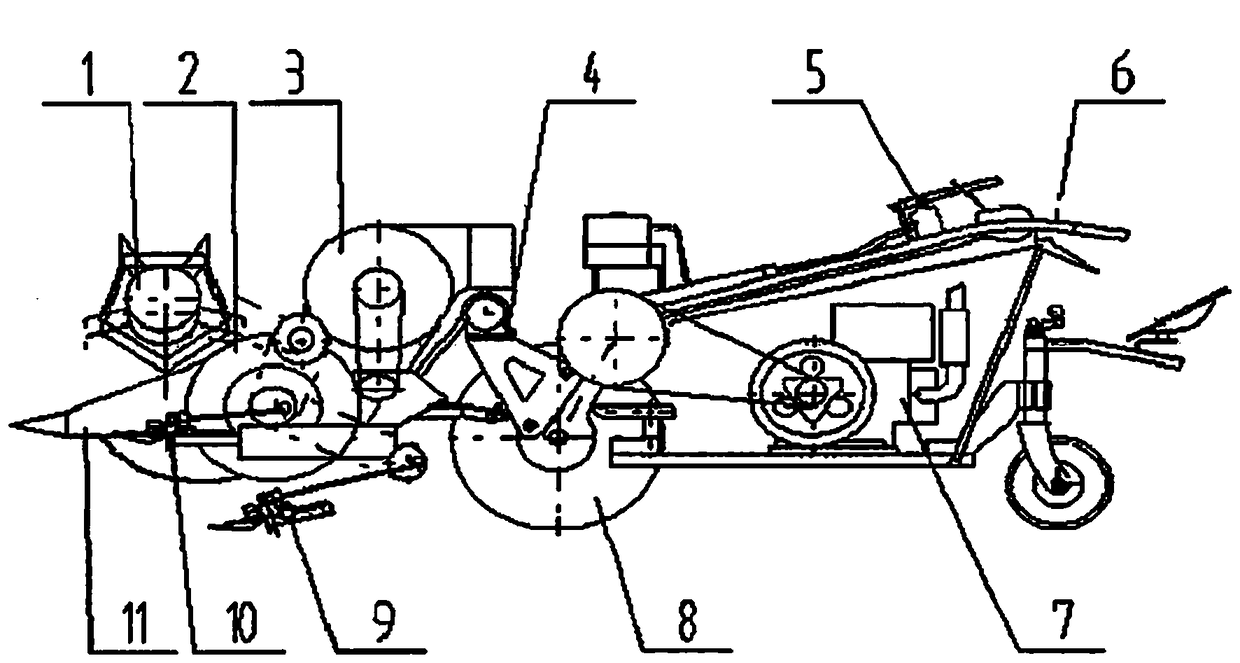

[0017] figure 1 The small and medium rice combine harvester mainly consists of a reel, a side conveying fan, a threshing device, a hitch, a hydraulic lifting mechanism, a hand-drawn chassis, an engine, an ultra-wide low-pressure tire, a secondary cutting mechanism, a primary cutting mechanism, Grain divider, transfer system, etc.; the hand-drawn chassis adopts the GN-71 walking tractor chassis; the engine is a diesel engine, which is arranged at the rear of the whole machine. After the power is output from the pulley, it should be respectively output to the walking tractor Chassis and working parts provide machine walking and working parts running power respectively through walking clutch and working clutch; The radius of described reel axle center to bullet tooth tip is 255mm, and rotating speed is 30r / min, and angular velocity is 4.58rad / s, The linear velocity of the tip of the spring tooth is 1.16m / s; the design of the side-mounted conveying fan is centrifugal, the impeller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com