Automatic aligning and feeding system for middle-sized cartridge-case-shaped workpieces

A technology of automatic arrangement and automatic discharge, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effect of low production cost, stable operation and improved industrial automation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

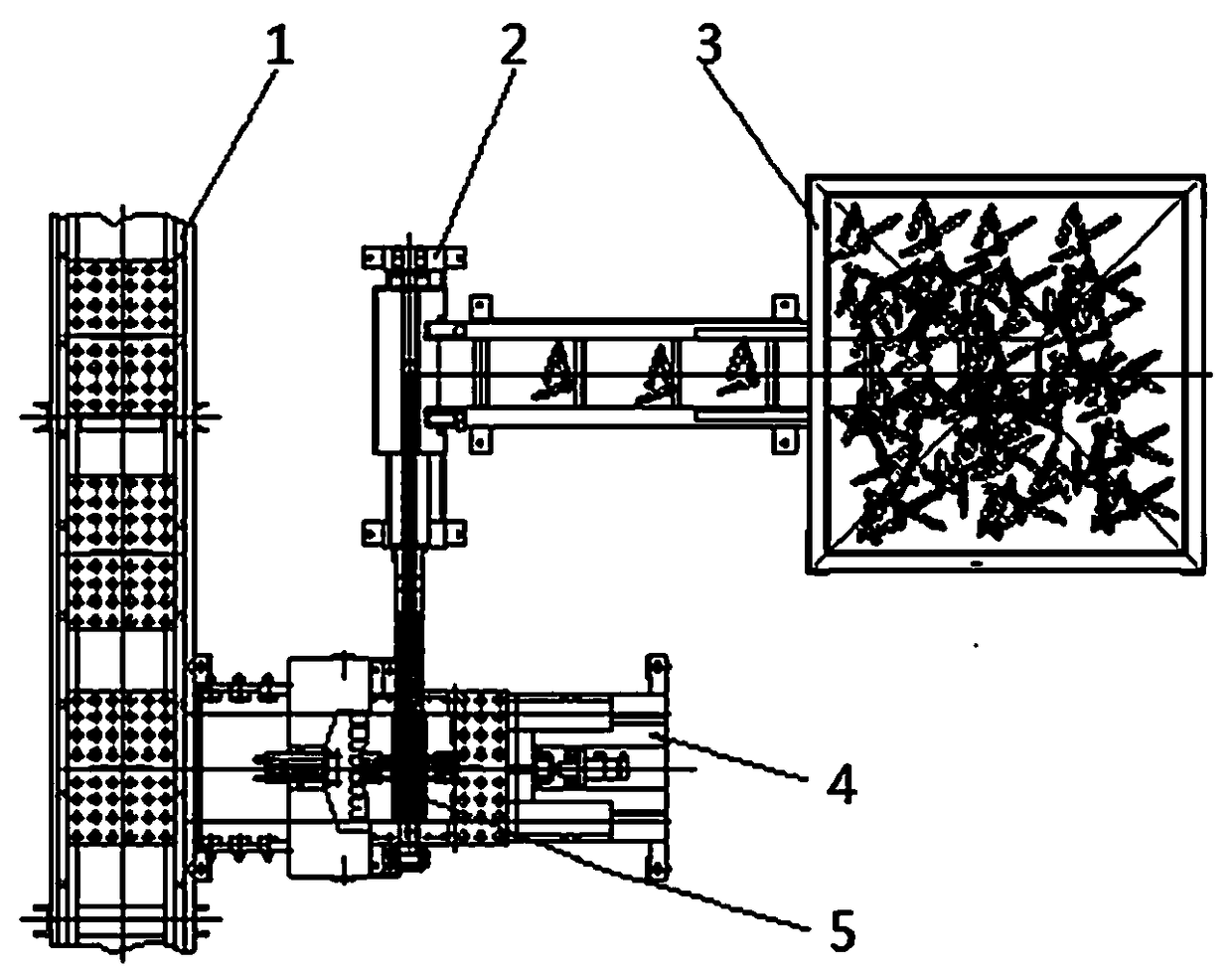

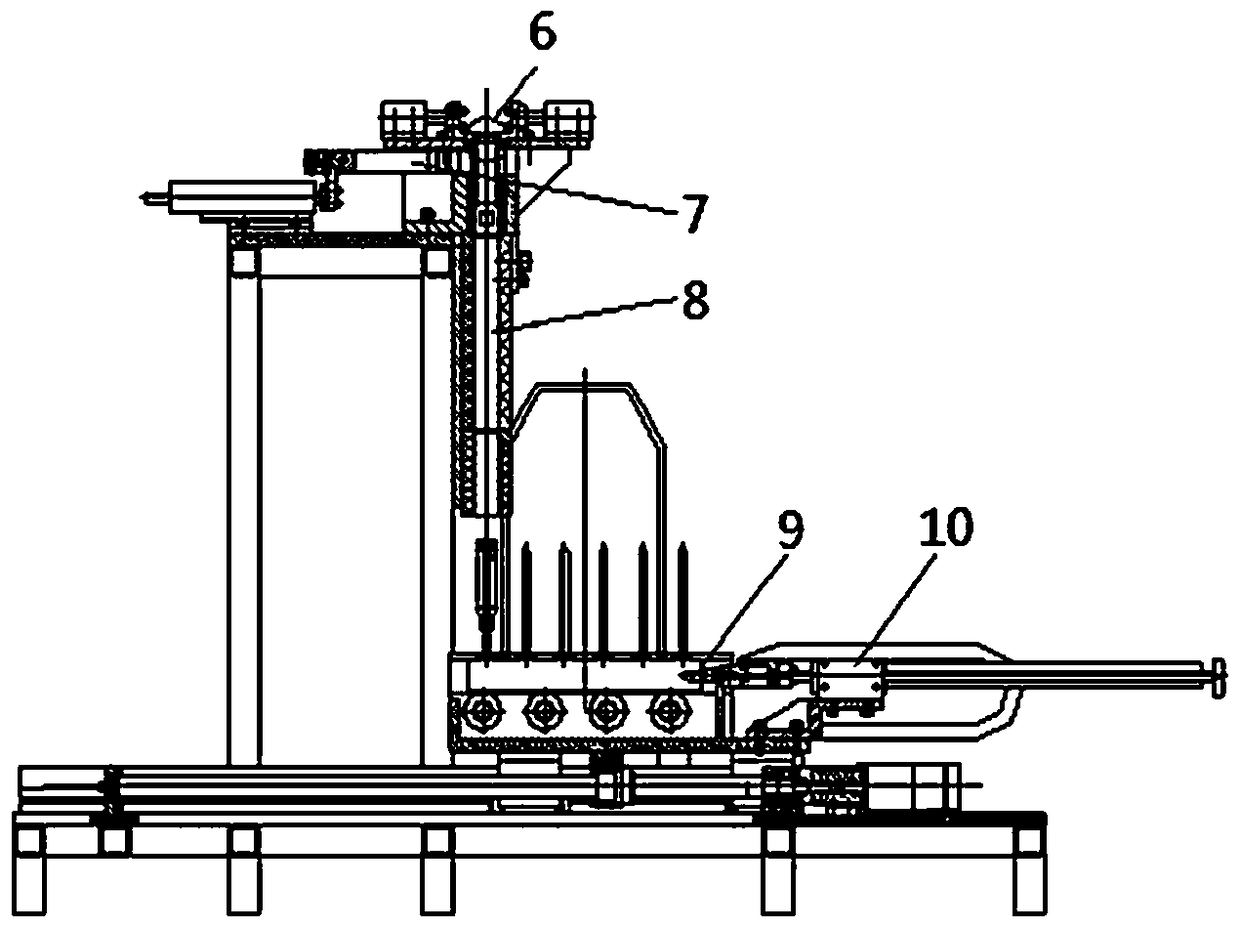

[0017] figure 1 The automatic arrangement and feeding system for medium and medium-sized bullet case-shaped workpieces is mainly composed of an automatic feeding bin, a carding and arranging mechanism, a branching and feeding (pinning) mechanism, a pallet transfer mechanism, etc.; the automatic feeding bin is composed of a bin main body and an automatic It is composed of a discharge elevator; the main body of the silo is shaped like a square funnel, which is used to store and accumulate the shell casings to be processed; the automatic discharge elevator is a rubber canvas flat belt conveyor, which is integrated with the main body of the silo , used to evenly send the bullet casings in the silo to the funnel of the carding mechanism. A baffle plate is installed at a distance of about 400 mm on the flat belt. When the elevator is working, the baffle plate will take out the bullet casings from the hopper; The carding arrangement mechanism is mainly composed of counter-rotating do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com