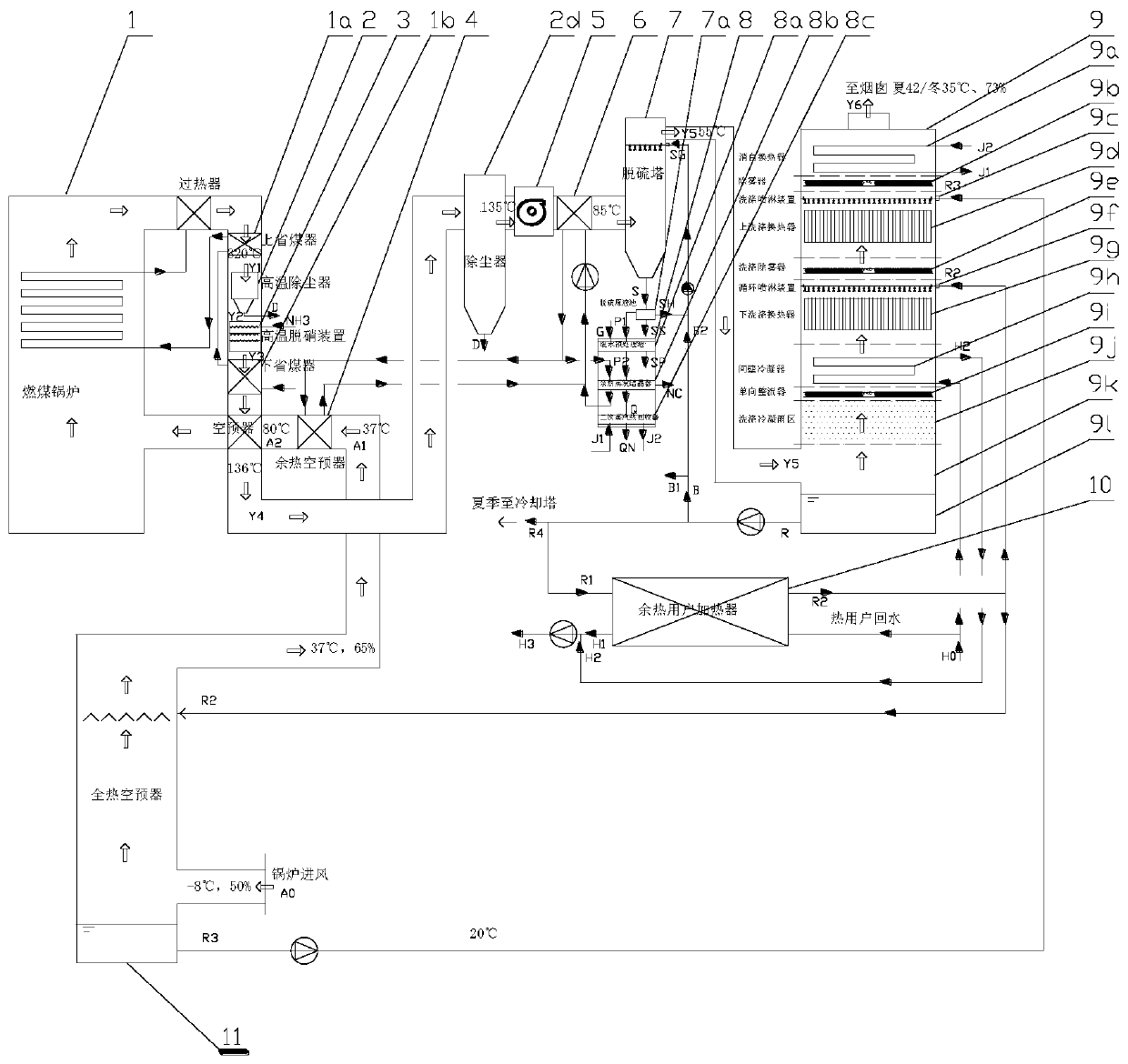

Waste heat driving based boiler smoke exhaust total component treatment and resource recycling mode

A resource-based, full-component technology, applied in the field of flue gas treatment and circular economy, which can solve problems such as reducing escapable pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0093] If it is not suitable to install the high-temperature dust collector 2 due to reasons such as on-site installation space, a conventional medium-low temperature dust collector 2d can be installed instead, wherein the flue gas inlet of the conventional medium-low temperature dust collector 2d communicates with the flue gas outlet of the boiler 2, The flue gas outlet of the conventional medium and low temperature dust collector 2d communicates with the flue gas inlet of the desulfurization tower 7 or the flue gas heat recovery device 6 in the middle temperature section. Other system processes and features of this specific embodiment are the same as those of specific embodiment 1.

specific Embodiment 3

[0095] If the existing boiler adopts the dry or semi-dry desulfurization method, that is, the desulfurization tower 7 of the wet method is not installed, the flue gas outlet of the flue gas heat recovery device 6 in the middle temperature section is changed to be connected with the cascade condensate film decontamination module 9 The flue gas inlet is connected. Other system processes and features of this specific embodiment are the same as those of the above-mentioned specific embodiment 1. At this time, the cleanliness of the flue gas after dry desulfurization, high-temperature dust removal, and high-temperature denitrification is very high. After that, various heat exchangers on the flue gas passage, including the medium and low temperature flue gas heating surface 1b, the existing air preheater of the boiler, The flue gas side of the heat exchange elements such as the flue gas heat recovery device 6 in the middle temperature section has solved the inherent problems such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com