Method and device for recovering dust of urea granulation

A technology of dust recovery and urea granulation, which is applied in the chemical industry to achieve the effects of small impact, low resistance and obvious recovery benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

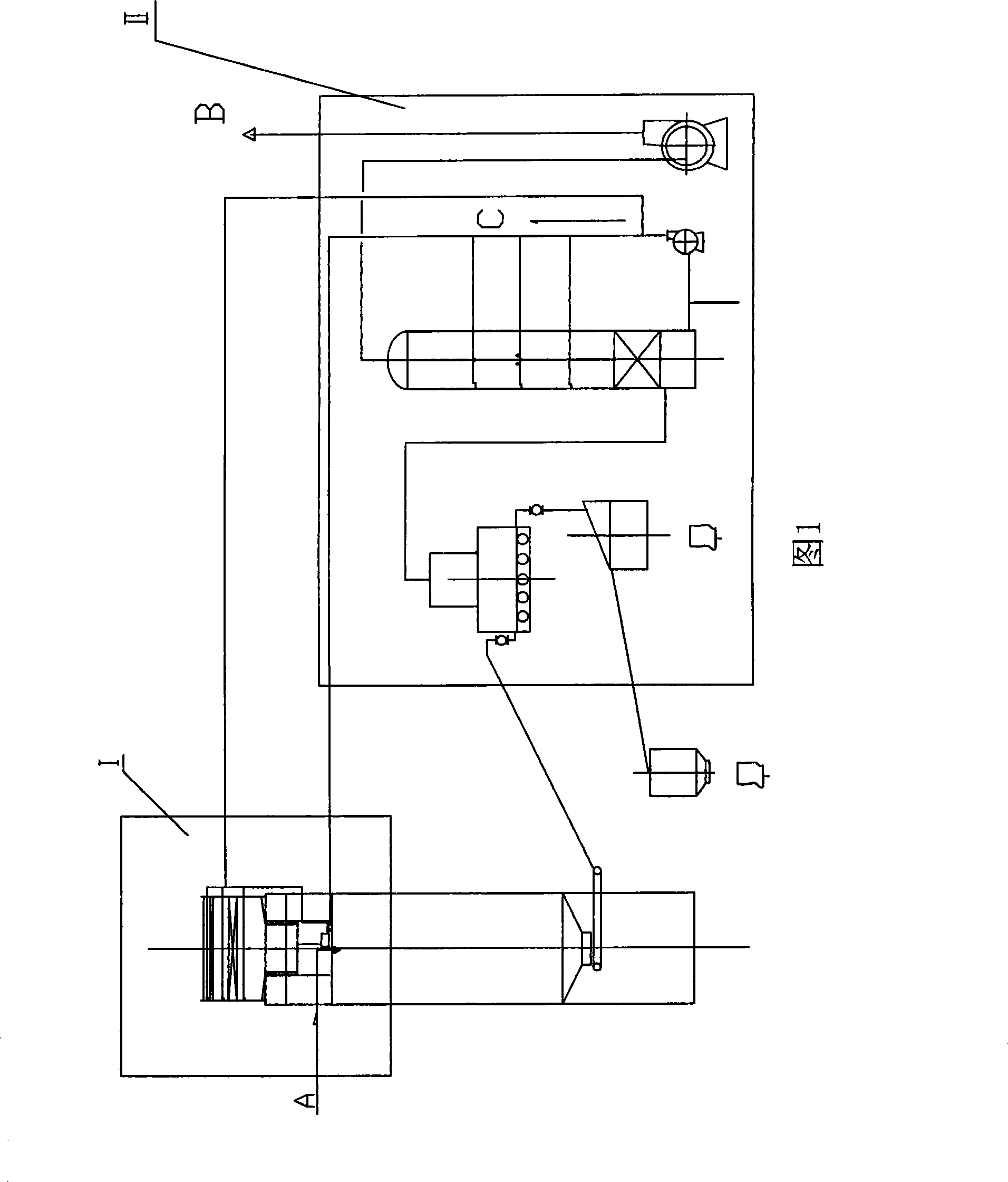

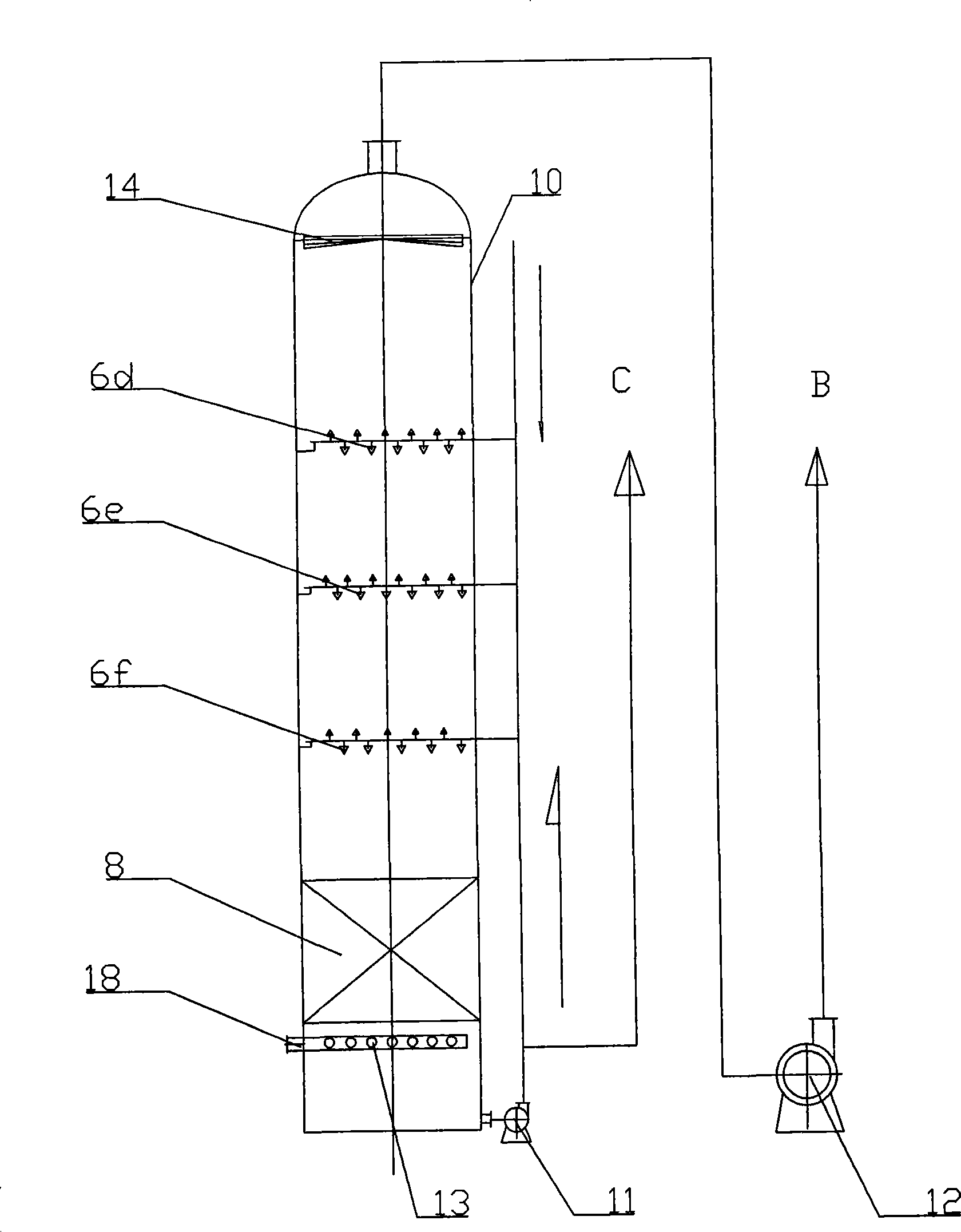

[0028] Taking the hydrolysis wastewater as the absorption liquid in parallel closed-circuit circulation in the devices (I) and (II) as an example, in conjunction with the drawings, non-limiting embodiments are described as follows:

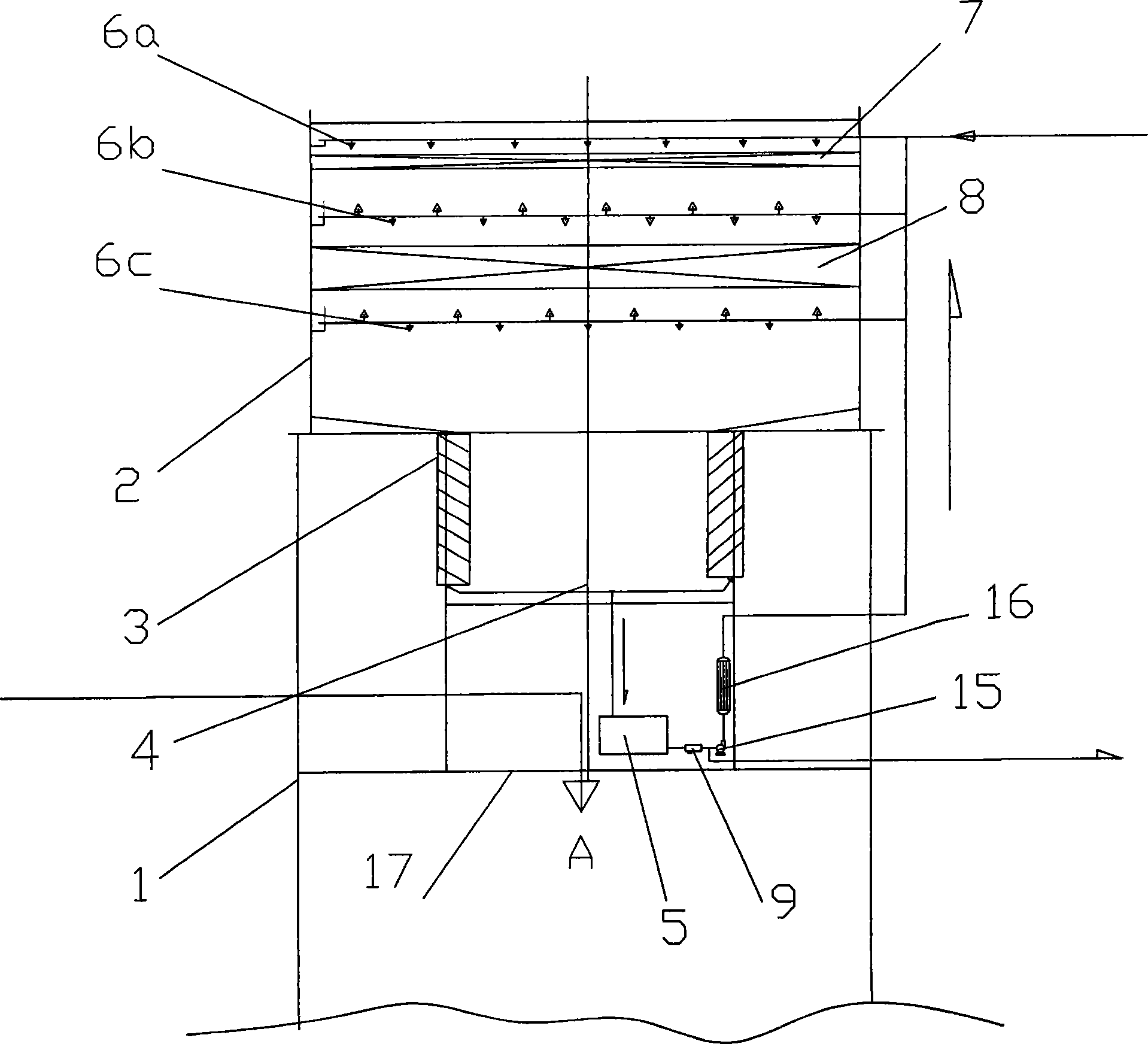

[0029] 1. Device (I): As shown in Figure 1, figure 2 As shown, the absorption cylinder 2 is fixed at the top of the prilling tower 1, and the gas distribution device 3 and the sump 4 are fixedly connected below it. The sump 4 is connected to the liquid storage tank 5 through a pipe, and the liquid storage tank 5 is fixed at On the urea granulation rack 17.

[0030] In the absorption cylinder 2, there are three-stage atomization and dust absorption spiral type non-blocking atomization nozzles 6a, 6b and 6c, of which 6b and 6c spray up and down; below the nozzle 6a is set a blade type defogging nozzle as shown in Figure 5 The plate 7 is provided with a vertical honeycomb grid filler 8 as shown in FIG. 6 between the nozzles 6b and 6c.

[0031] The outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com