Polyester filament yarn POY finish and preparation method thereof

A technology of polyester filament and oil agent, which is applied in fiber types, textiles and papermaking, fiber treatment, etc. It can solve problems such as unstable viscosity, temperature and viscosity characteristics, easy to cause wool, broken ends, and affect production efficiency, etc., to achieve Excellent antistatic performance, solve the serious problem of coking, and improve the effect of high-quality products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

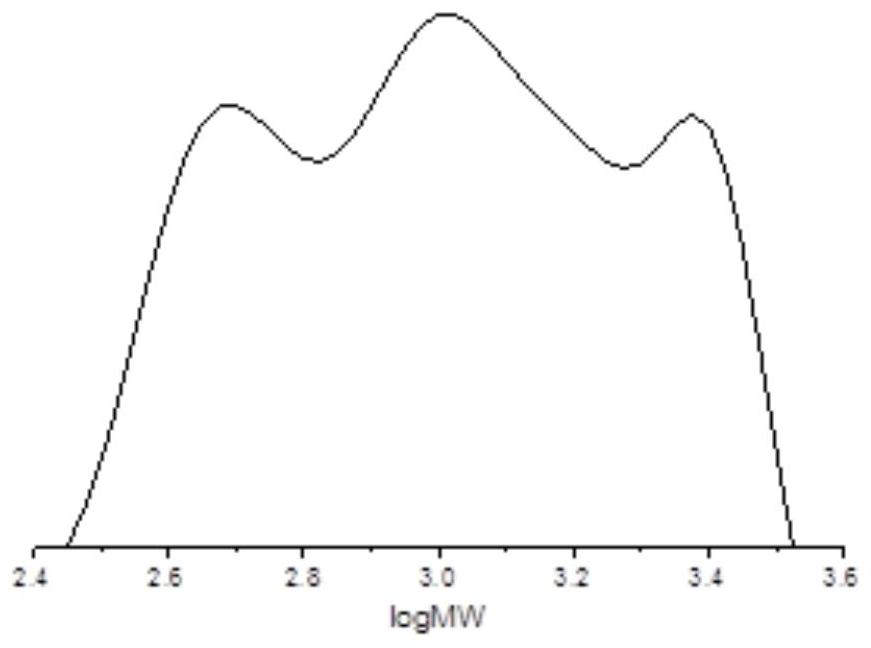

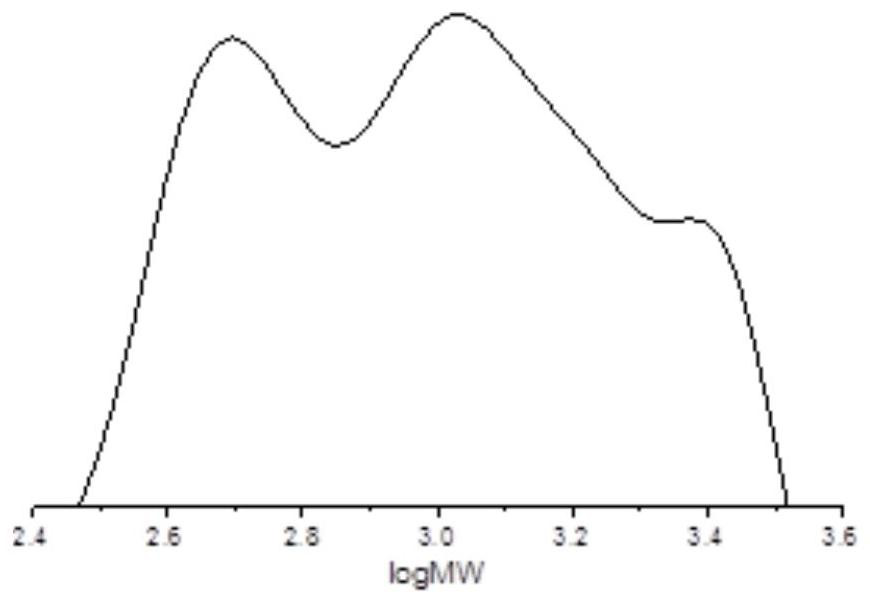

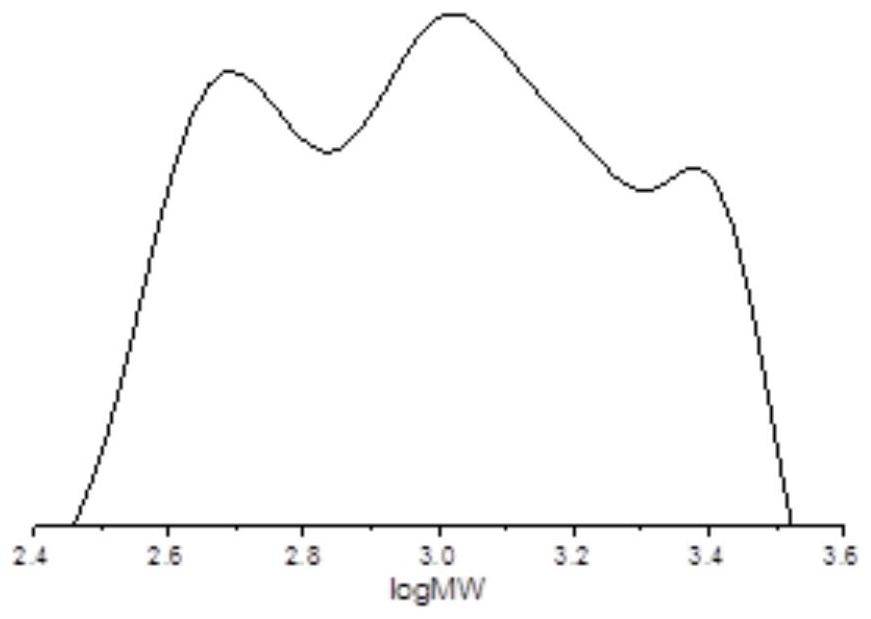

Image

Examples

preparation example Construction

[0046] The preparation method of polyester filament POY oil agent comprises the following preparation steps:

[0047] (1) Put the emulsifier and antistatic agent into the reaction kettle in proportion, and stir for 0.5-1h at a stirring rate of 550-600r / min at 40-60°C;

[0048] (2) Put base oil and smoothing agent into the reaction kettle, continue to stir for 30-60min, then drop in additives, stir naturally and filter to obtain polyester POY oil;

[0049] Also include anti-yellowing agent in the additive, the consumption of anti-yellowing agent is 0.1-2wt% of the total oil agent, the molecular weight of described anti-yellowing agent is 1000-1500, the preparation method of anti-yellowing agent is: Phosphorus trichloride, phenol and triethylamine react at 20-30°C under normal pressure to prepare the intermediate product triphenyl phosphite; then the intermediate product triphenyl phosphite and polyethylene glycol monostearate The ester is transesterified at 105-120°C under nor...

Embodiment 1

[0050] Embodiment 1: a kind of polyester filament POY oil agent, by weight percentage, is made up of following components:

[0051] Base oil 11%, of which glycerol monopalmitate 2.5%, glycerol monostearate 2.5%, lauryl oleate 2.5%, diisooctyl sebacate 2.5%, industrial white oil 1% ;

[0052]Smoothing agent 74%, of which lauric acid atactic polyoxyethylene polyoxypropylene ether 1200 8%, propylene glycol atactic polyoxyethylene polyoxypropylene ether 1500 6%, glycerin atactic polyoxyethylene polyoxypropylene ether 3000 6% , Butanol Atactic Polyoxyethylene Polyoxypropylene Ether 1000 6%, Butanol Atactic Polyoxyethylene Polyoxypropylene Ether 2500 6%, Lauryl Alcohol Atactic Polyoxyethylene Polyoxypropylene Ether 1500 6%, Isomer Thirteen Alcohol Atactic Polyoxyethylene Polyoxypropylene Ether 1000 6%, Methyl-terminated Butyl Polyether 2000 6%, Lauric Acid Polyoxyethylene (9) Ether 6%, C12-C14 Fatty Alcohol Block Polyoxyethylene Polyoxygen Propylene ether 1100-1500 6%, lauric acid...

Embodiment 2

[0058] Embodiment 2: a kind of polyester filament POY oil agent, by weight percentage, is made up of following components:

[0059] 7% base oil, including 3% glycerol monopalmitate, 3% glycerol monooleate, and 1% industrial white oil;

[0060] Smoothing agent 75%, of which stearic acid atactic polyoxyethylene polyoxypropylene ether 1500 8%, glycerol atactic polyoxyethylene polyoxypropylene ether 3000 7%, butanol atactic polyoxyethylene polyoxypropylene ether 1000 6%, Butanol Atactic Polyoxyethylene Polyoxypropylene Ether 2500 6%, Isogenic Tridecyl Atactic Polyoxyethylene Polyoxypropylene Ether 1000 6%, Methyl-terminated Butyl Polyether 20006%, Lauric Acid Poly Oxyethylene (9) ether 6%, hydrogenated ricinoleic acid polyoxyethylene (20) ether 6%, C12-C14 fatty alcohol block polyoxyethylene polyoxypropylene ether 1100-1500 6%, lauric acid polypropylene glycol 400 monoester 6%, Polyethylene Glycol 300 6%, Polypropylene Glycol 1000-2000 6%; Emulsifier 10%, of which 5% isooctyl alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com