Stroke-adjustable movable temple device

An adjustable temple technology, applied in the direction of textile, textile, papermaking, weaving auxiliary equipment, etc., can solve the problems of affecting weaving efficiency, increasing the difficulty of parts manufacturing, harsh noise, etc., to improve precision and precision retention, Effects of reducing use and maintenance costs and improving accuracy retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

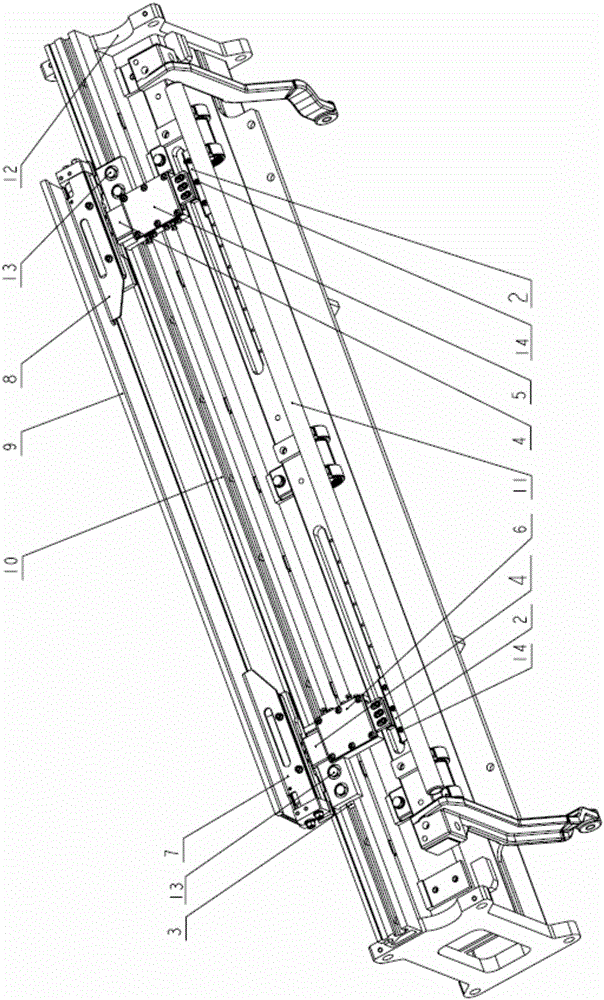

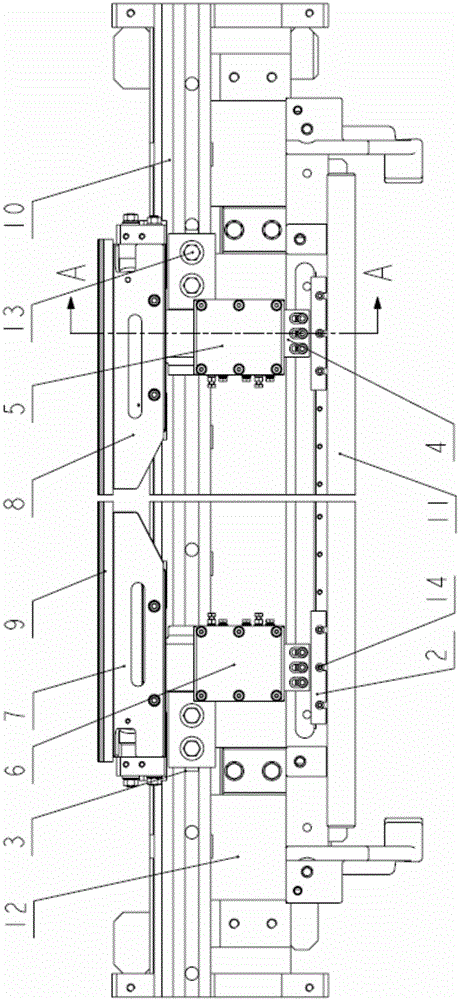

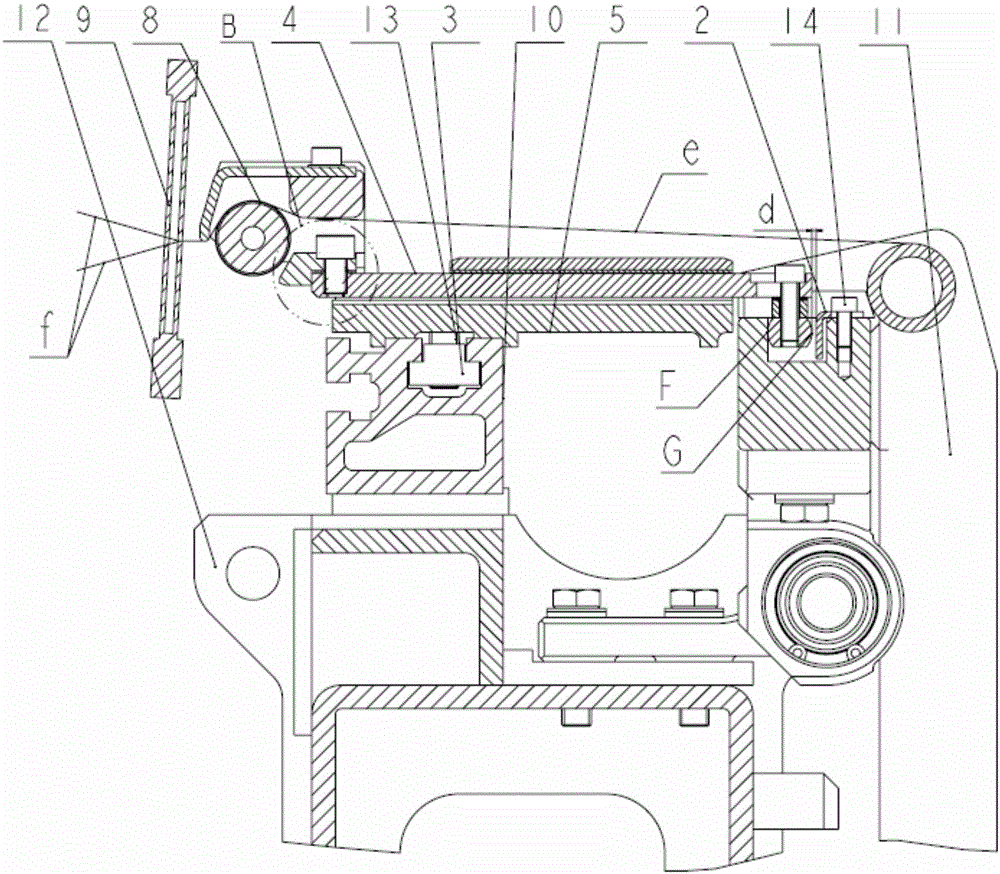

[0026] see Figure 1 to Figure 4 As shown, a movable temple device with adjustable stroke includes two moving bodies 4, a right moving body supporting seat 5, a left moving body supporting seat 6, a left stabbing shaft 7, a right stabbing shaft 8, a front swing beam 11. Chest beam frame 12, the left mobile body support seat 6 and the right mobile body support seat 5 are symmetrically arranged on the left and right sides of the fabric e, the left mobile body support seat 6 and the right mobile body support seat 5 pass T-shaped screws 3 , Bolts 13 are fixed on the supporting profile 10 of the chest beam frame 12 of the loom, the position is adjustable left and right, the middle parts of the two moving bodies 4 are respectively matched with the moving body channels of the left moving body supporting seat 6 and the right moving body supporting seat 5, The left stabbing shaft 7 and the right stabbing shaft 8 are respectively installed on the rear end of the corresponding moving bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com