Ash removal method for radiant coil of fuel oil heating furnace

A heating furnace and fuel oil technology, applied in the field of ash cleaning, can solve the problems of high labor intensity, waste of energy, poor working environment, etc., and achieve the effects of simple operation, reduced labor intensity and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through embodiments and accompanying drawings. But it is not a limitation of the present invention.

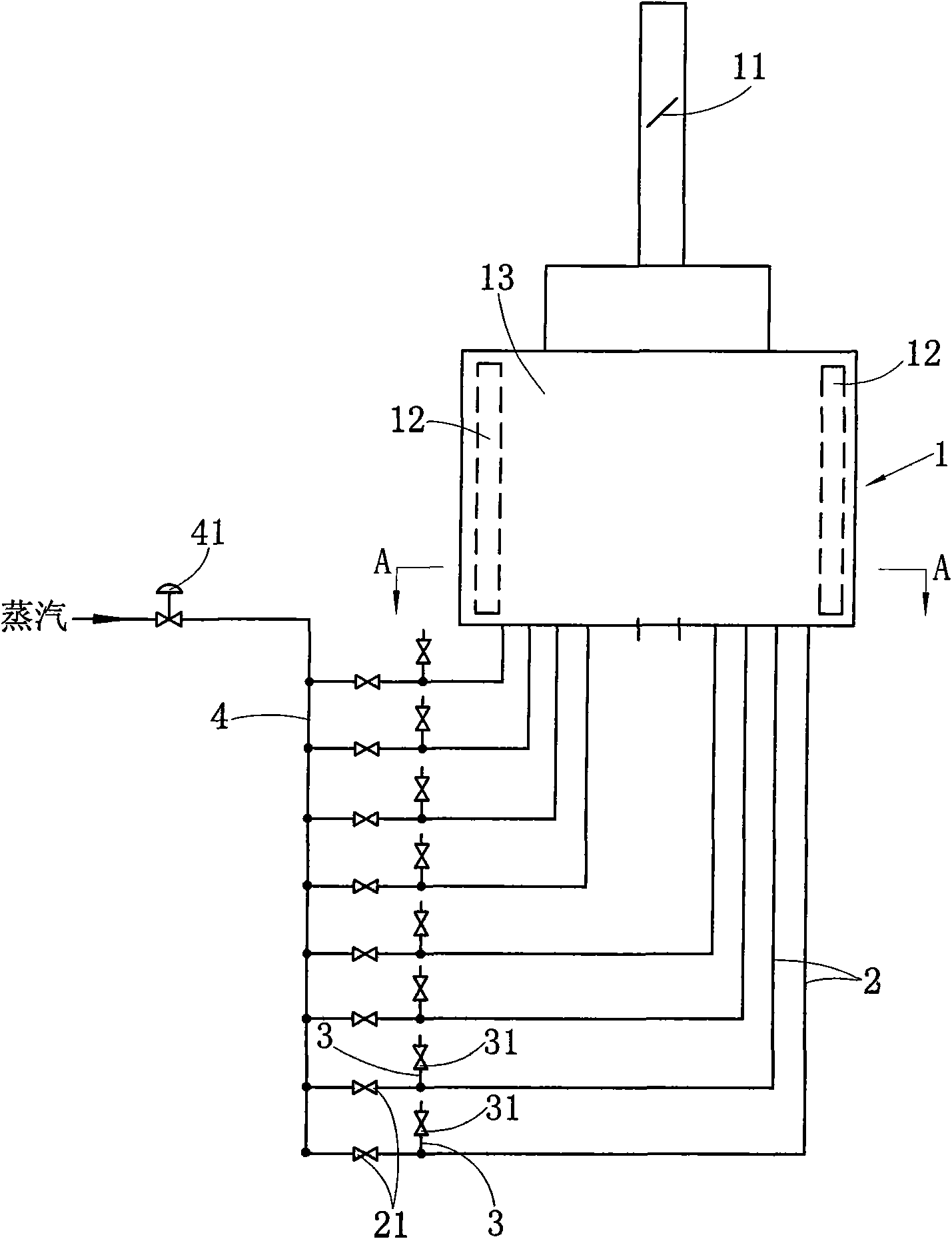

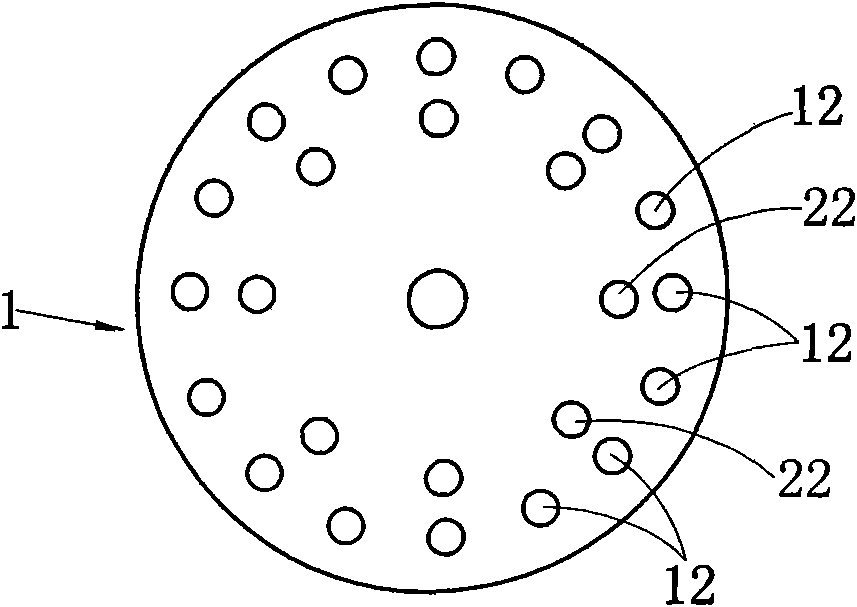

[0018] See attached figure 1 , figure 2 , the soot cleaning method of the furnace tube in the radiant section of the fuel heating furnace, the process steps are: first cut off the fuel oil supply of the fuel heating furnace 1, stop the combustion of the fuel heating furnace 1, and then fully open the upper damper 11 of the fuel heating furnace 1, Then, with steam as power, the water in the 8 water inlet pipes 2 connected to the bottom of the fuel heating furnace 1 is sent into the furnace 13, relying on the shock wave generated by the evaporation of water in the furnace 13, the furnace tube 12 in the radiant section of the furnace 13 is The dust accumulation on the outer wall is removed.

[0019] In the above cleaning method:

[0020] The fuel oil heating furnace 1 adopts a natural convection oil heating furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com