Pneumatic tension control device

A technology of tension control and tension roller, which is applied in the direction of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of discontinuity, cumbersome and troublesome adjustment methods, and achieve efficiency, improve variety adaptability and fabric quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

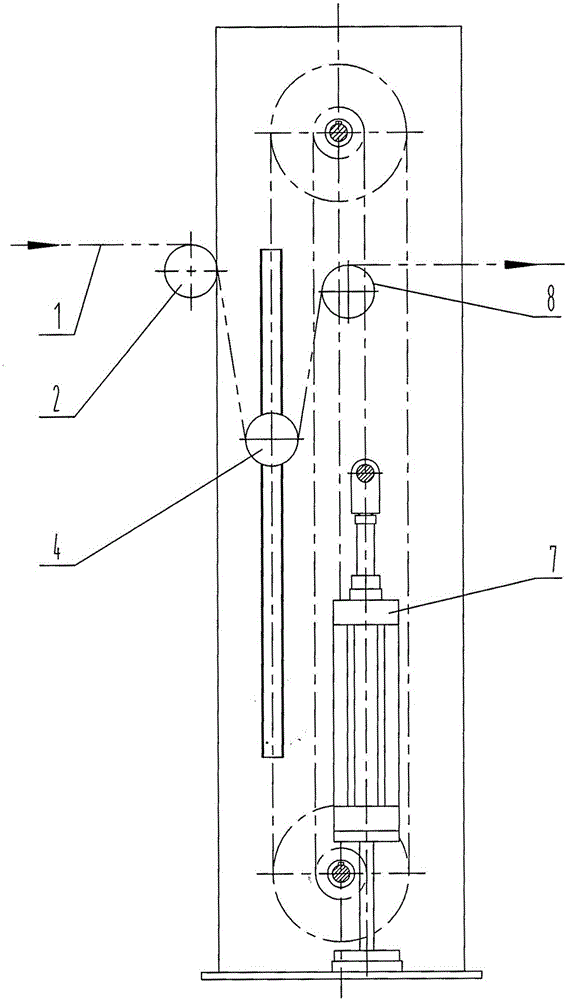

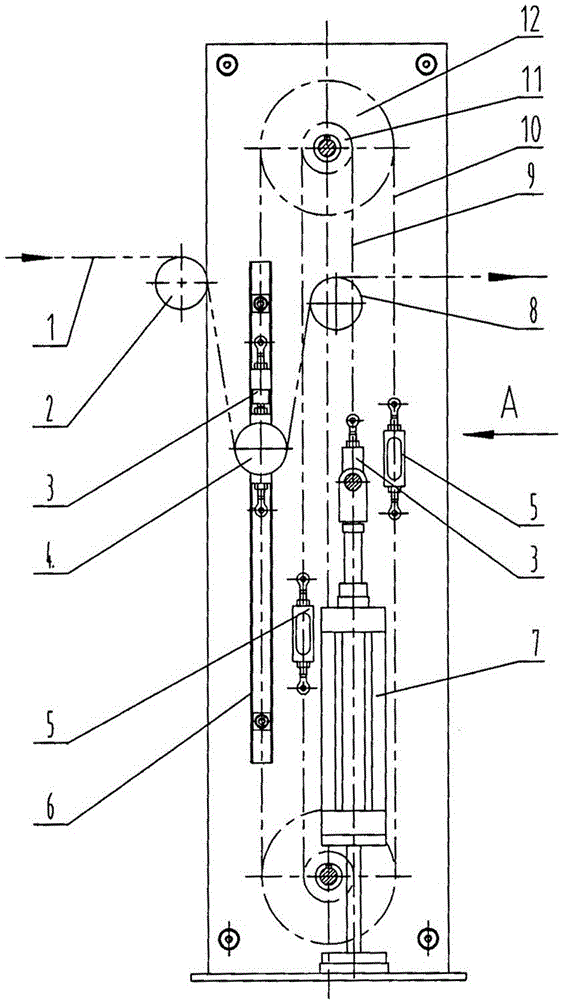

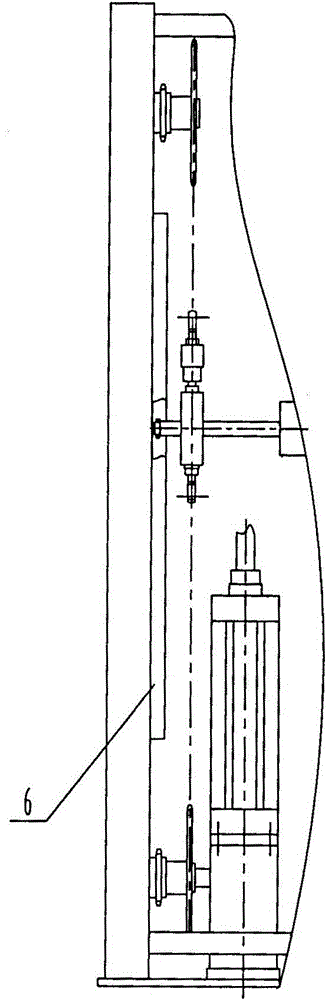

[0016] like figure 2 , 4 As shown, the pneumatic tension control device of the present invention comprises a frame composed of left and right wall panels 13, 19 and upper and lower cross braces 17, and the first guide roller 2 arranged in front of the frame is arranged in a vertical manner. The left and right cylinders 7 installed in the frame, the left and right cylinders 7 are connected with the bottom surface of the left wallboard 13 and the right wallboard 19 through the cylinder base 16 respectively, and the piston rods of the left and right cylinders 7 pass through the cylinder joint 15 is connected with the cylinder synchronous shaft 14, and the two ends of the cylinder synchronous shaft 14 are respectively suspended on the left and right cylinder chains 9 located on both sides of the cylinder synchronous shaft 14 through the chain joints 3 for adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com