Technique for producing chromonema, yarn

A production process and dyed silk technology, applied in the direction of liquid/gas/steam yarn/filament processing, etc., can solve the problems that cannot fundamentally solve the problem of winding density and quality, affect the quality of high-grade yarn-dyed fabrics, and the imported machine is expensive , to achieve the effects of shortening the production cycle, saving dyes and chemicals, and improving the product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The manufacturing process of dyed silk of the present invention, yarn, step is as follows:

[0016] 1. Spinning: melt and spin the polyester slices polymerized by petrochemical products into continuous long yarns and silk threads;

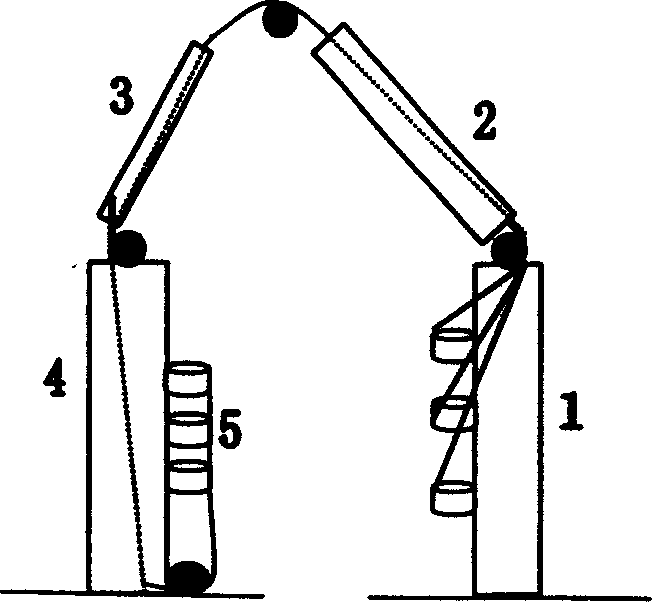

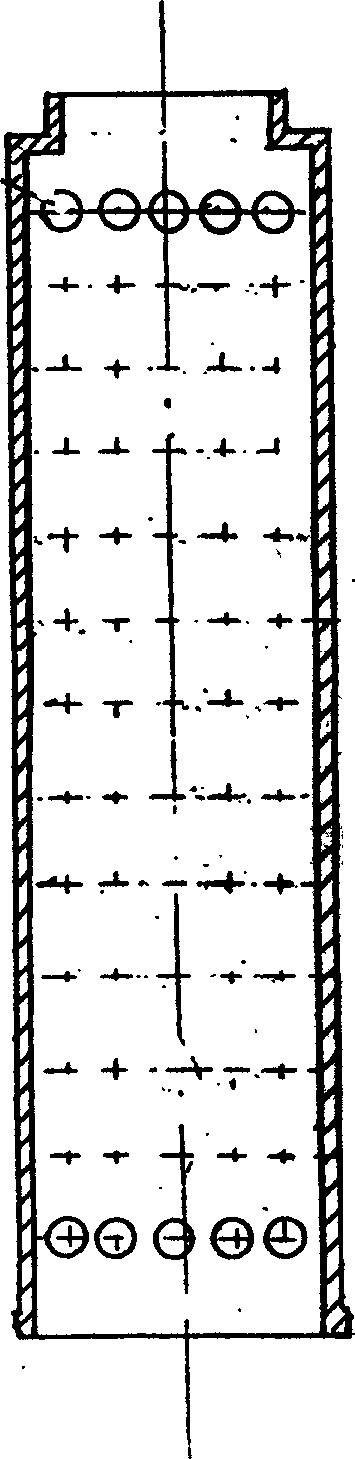

[0017] 2. Texturing: use the spun long yarn and silk thread figure 1 The texturing device shown is preheated, shaped and texturized according to the conventional texturing process, and the weight and density of the wound yarn and silk are controlled by the silk sensor on the creel 5 and the rotational speed of the drum shaft, according to the winding density 0.3-0.5g / cm 3 The filaments and yarns are directly wound on the plastic or steel cylindrical bobbin whose wall is densely covered with leaks (see figure 2 )superior. Usually, the diameter of the plastic or steel cylindrical bobbin is 4-10cm, and the height is 24-32cm. The thickness of the silk and yarn wound on the bobbin is 3-9cm, so that the weight of the coiled pellets is 3000± 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com