Patents

Literature

32 results about "Protein fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Protein fibers are those produced by animals. This family of fibers includes wool, cashmere, angora, alpaca, mohair, yak, camel, qiviut and silk.

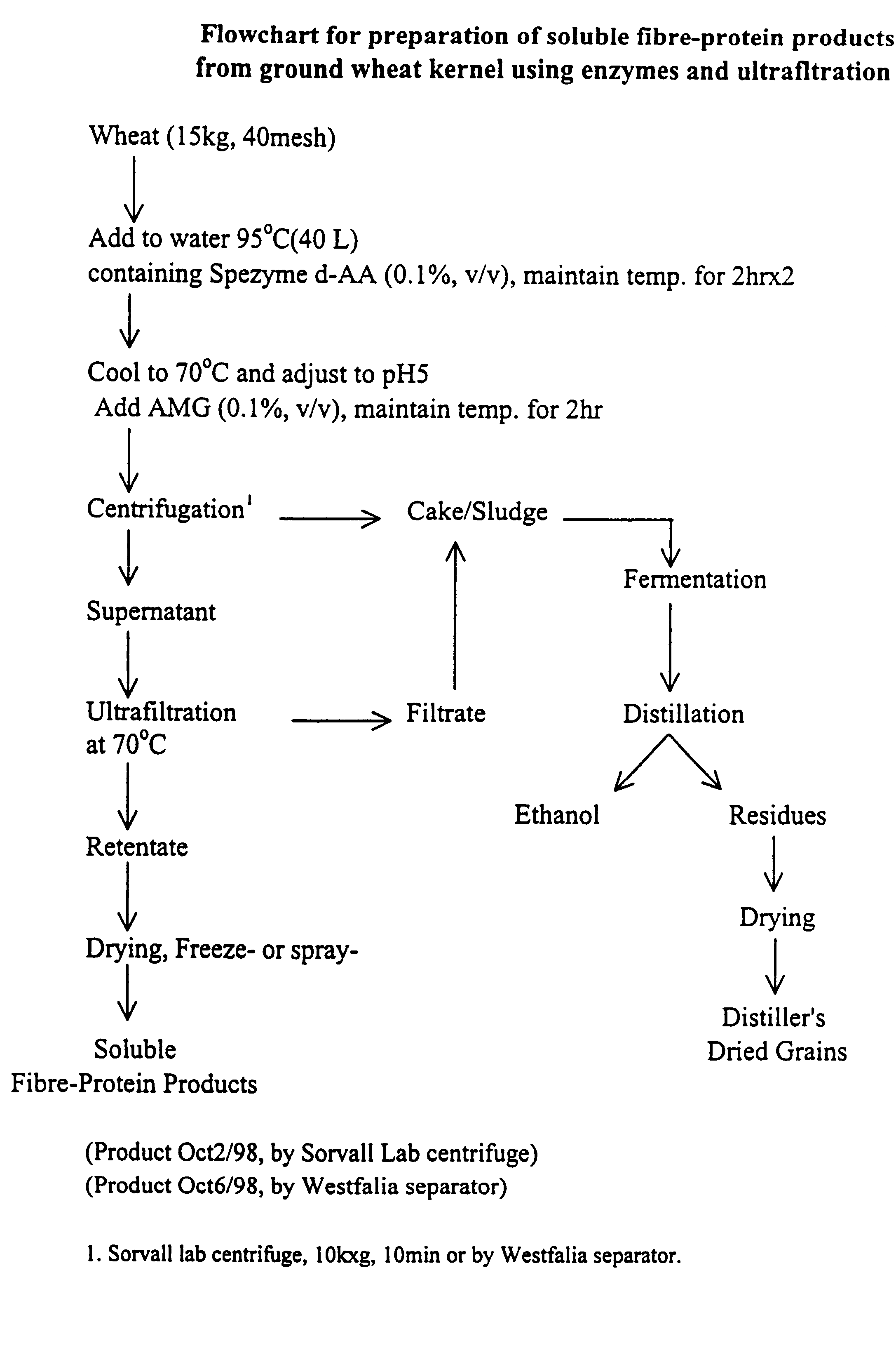

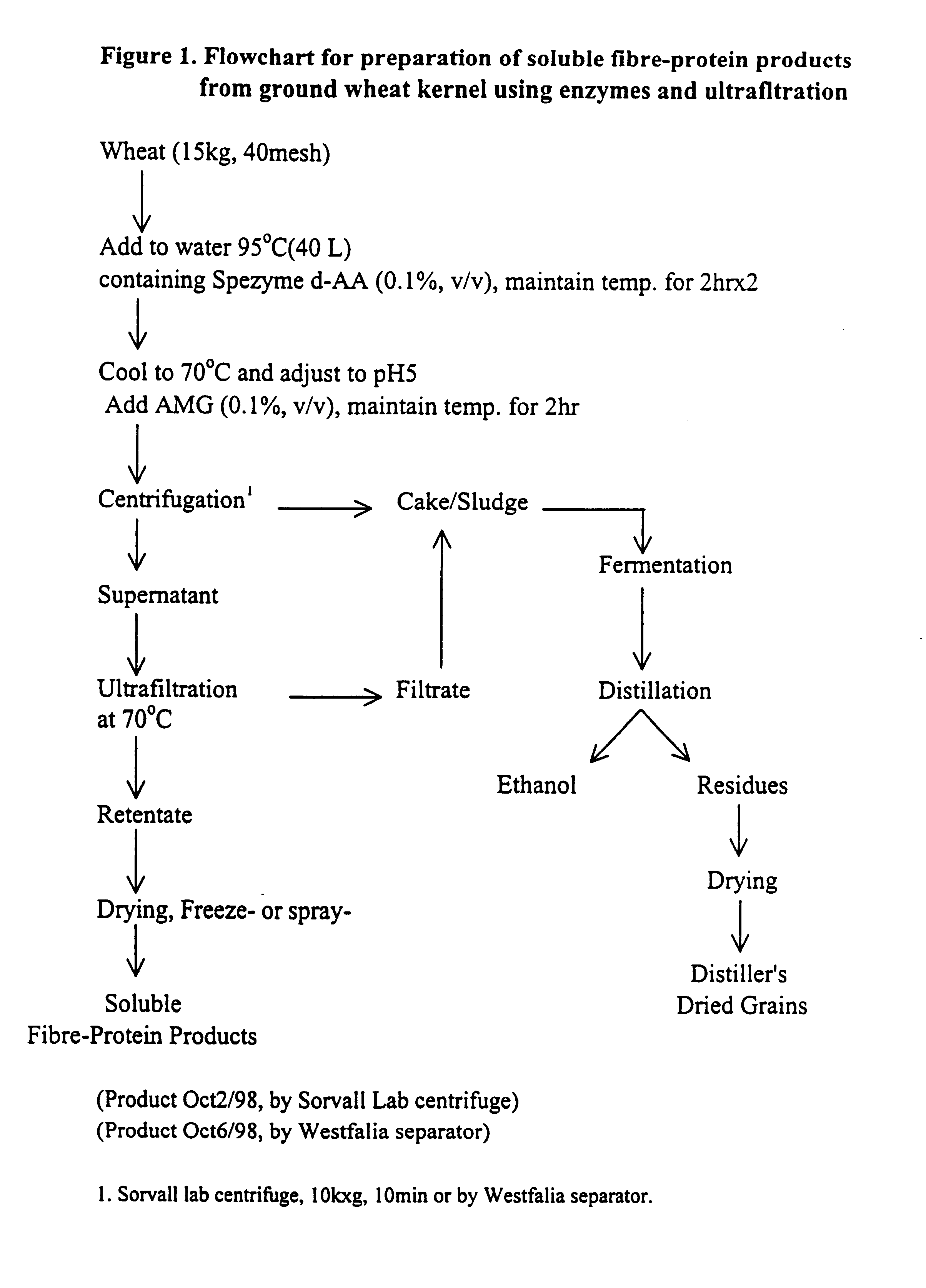

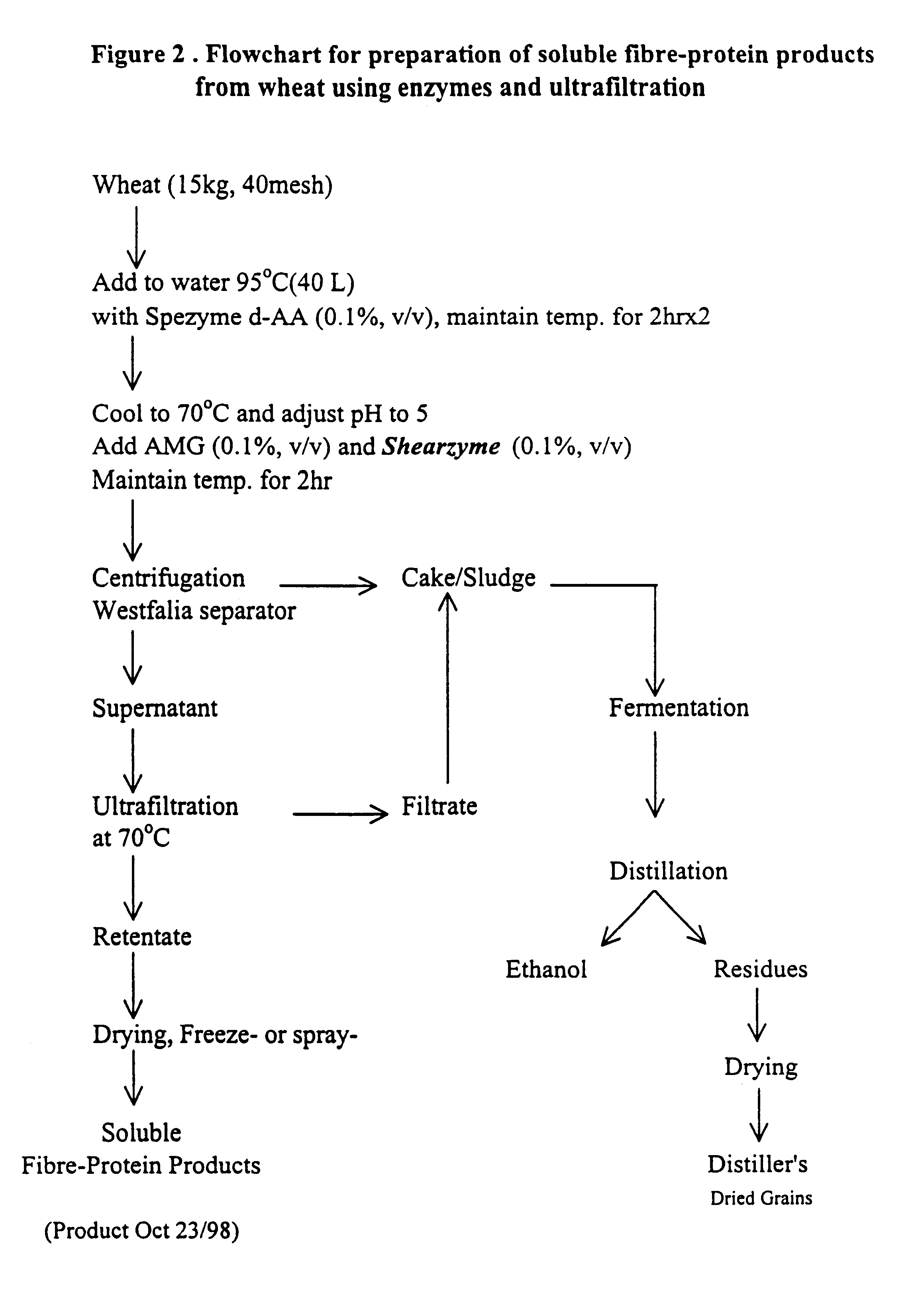

Functional, water-soluble protein-fibre products from grains

Novel water-soluble free-flowing protein-fibre products are provided from cereal grains, such as wheat, free from starch, bran and low molecular weight degradation products thereof. Starch contaminants in soluble fractions of the cereal grains are removed by enzymatic degradation and separation. The protein to fibre ratio of the product may be modified by enzymatic treatment. Such materials are useful in a wide variety of food application.

Owner:MAZZA GIUSEPPE +4

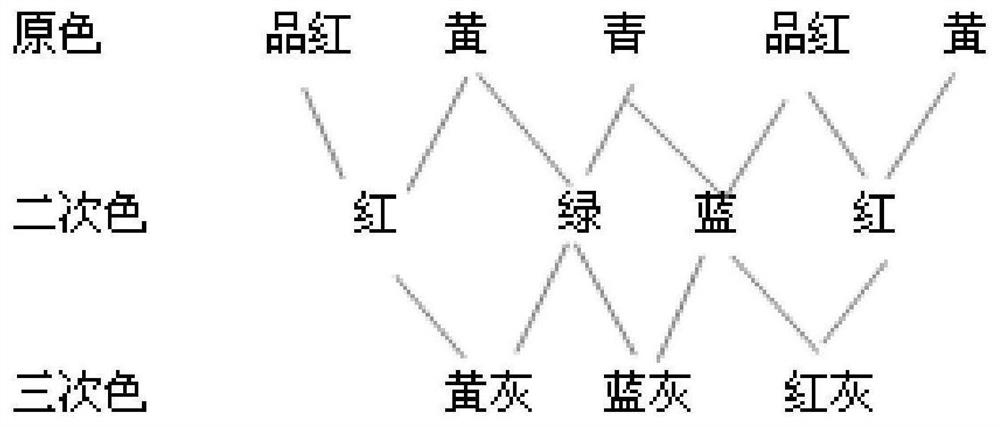

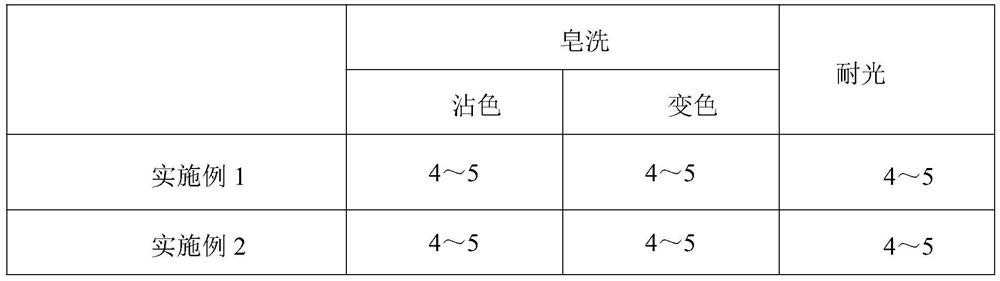

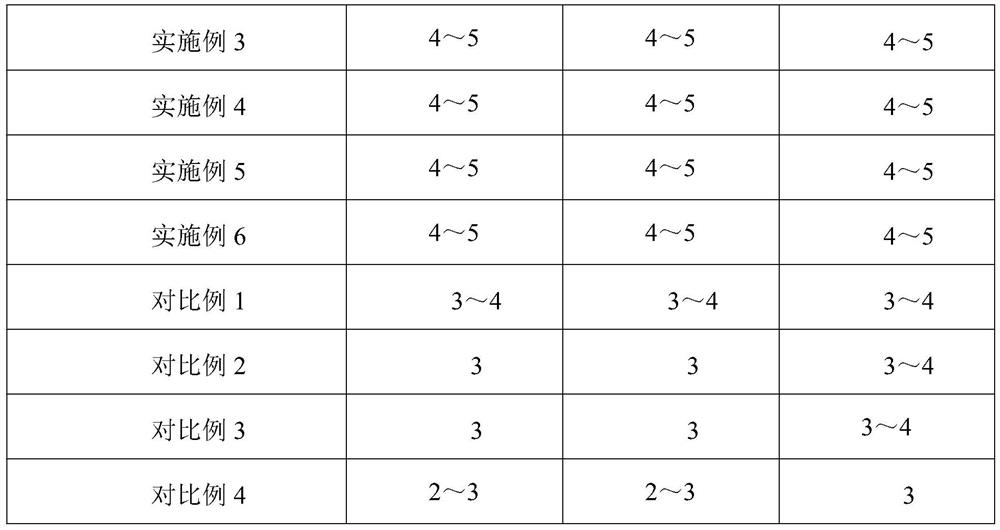

Dark black active dyestuff having high colour fixing rate

The invention provides an dark black reactive dye having high color fixation rate and compounded of three-primary color components: dark blue, fuchsine and orange components and the synthesizing method thereof, where the weight percents of the navy, fuchsine and orange components are (40-85)%, (5-30)%, and (5-25)%, respectively. And it has characters: it has very high blackening; color fixation rate up to above 80% at standard color and cplor of dyeing liquor residue is low, having good environmental benefits; dyeing curves of component to fiber are completely consistent; the dyed fabrics have good color uniformity. And it is especially applied to exhaustive dyeing of fibrin, protein fibre and polyarmide fiber.

Owner:大连华成中瑞科技有限公司

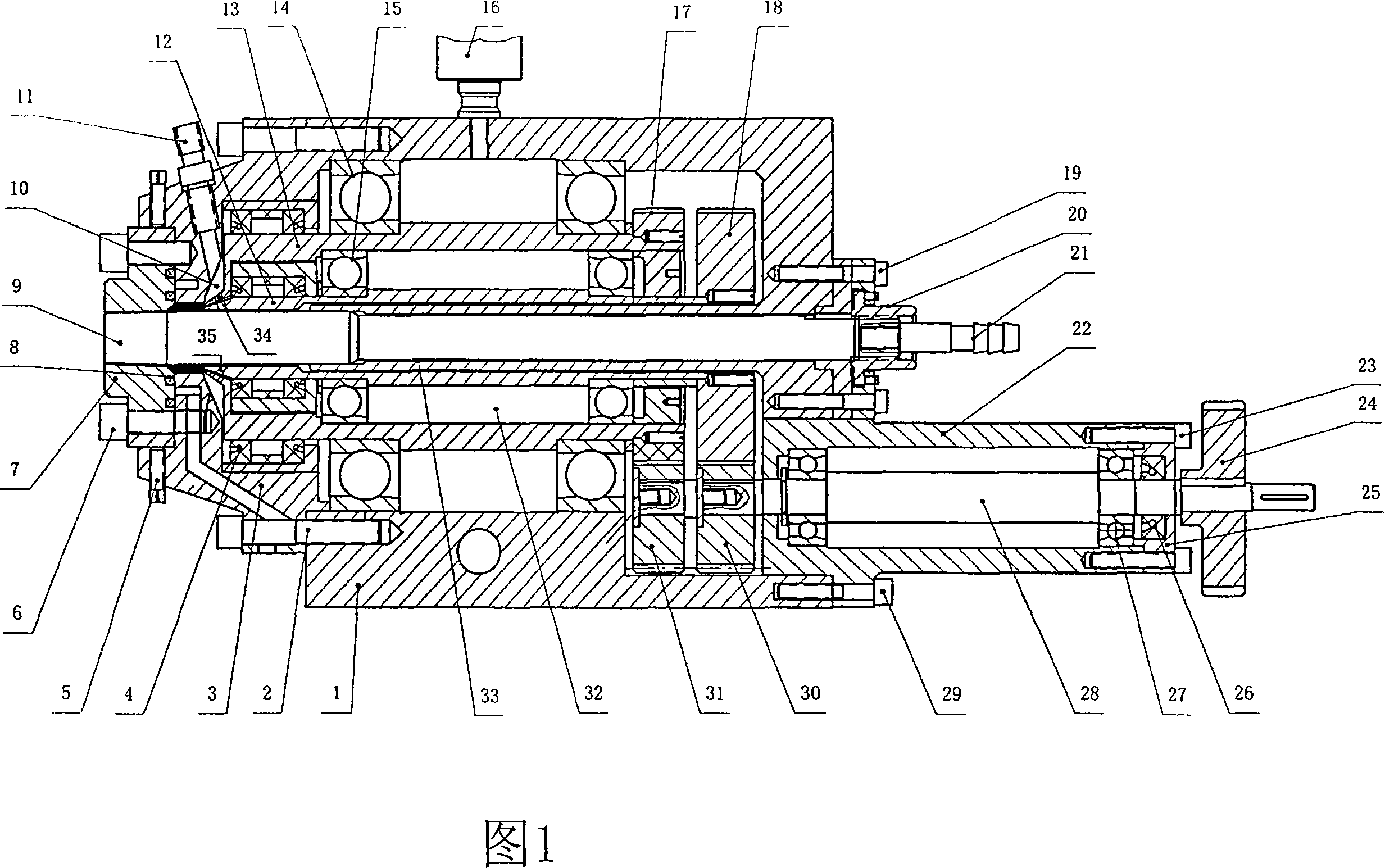

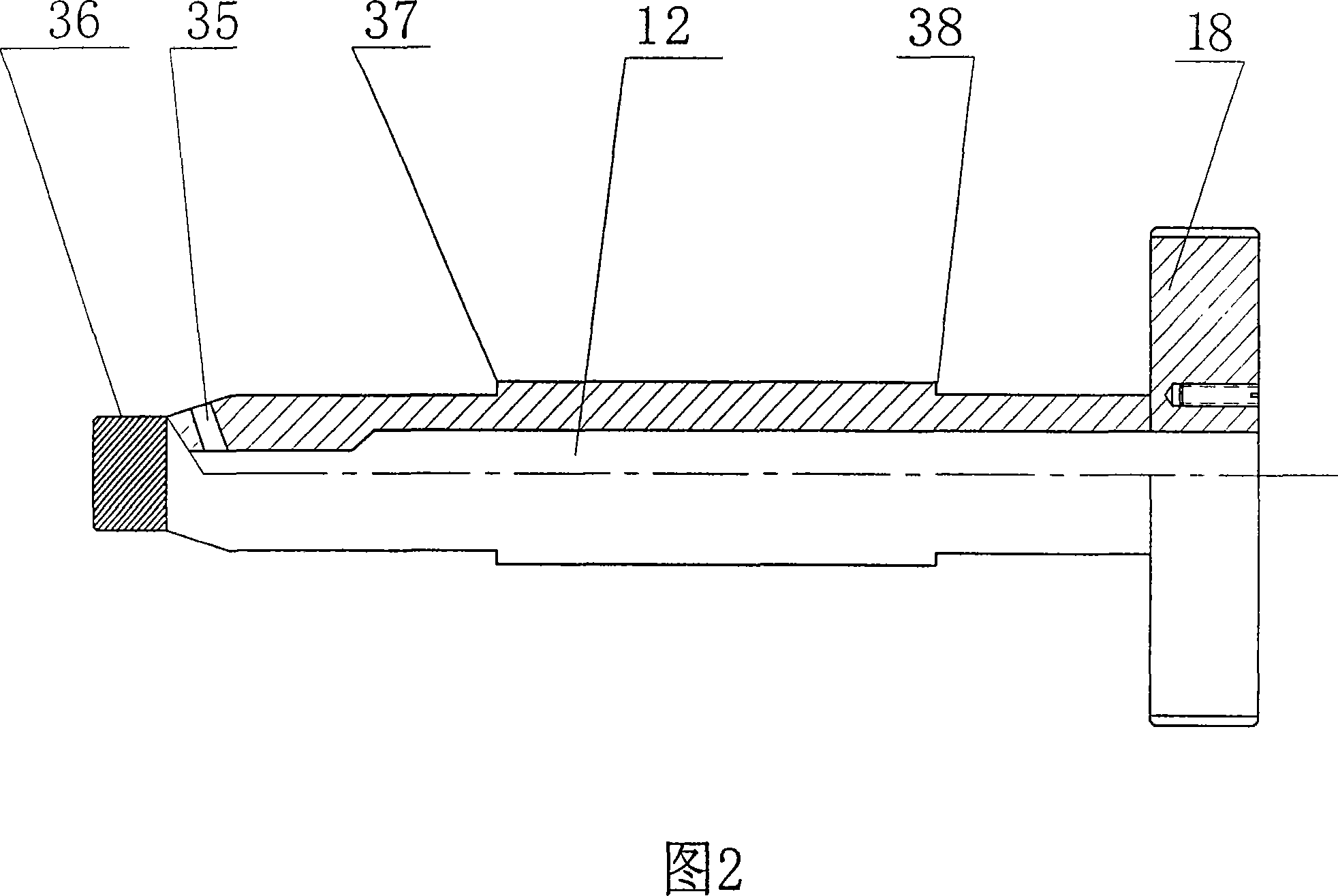

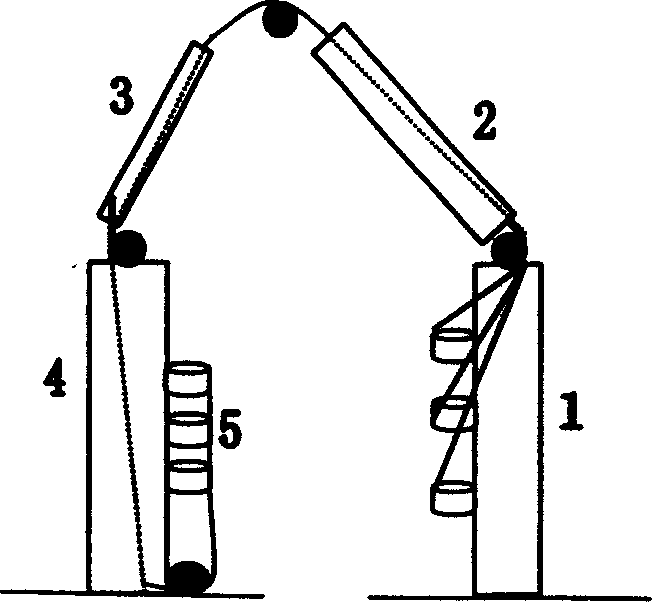

Collagen fabric casing for sausage knitting and former device

InactiveCN101099500AEvenly distributedHigh mechanical strengthSausage casingsFiberAgricultural engineering

The present invention discloses a collagen protein fibre casing weaving-forming machine. It includes the following several portions: machine frame with internal cavity, forming spindle, weaving sleeve, storage flange and ring-shaped nozzle component. Said invention also provides the concrete structure of every above-mentioned portion and connection mode of all the above-mentioned portions, and also provides the working principle of said casing weaving-forming machine and its concrete operation method.

Owner:柳州市宏升胶原蛋白肠衣有限公司

Tubular Food Casing Having a Smoke-permeable Glued Seam

A food casing is described with or without flat reinforcement insert and a smoke-permeable costing, preferably of protein, cellulose or acrylic. The insert is preferably a consolidated nonwoven or spunbonded nonwoven, a woven fabric, loop-formingly knitted fabric, laid fabric or loop-drawingly knitted fabric. The flat strip is glued to form a tube using a smoke-permeable gluing medium, preferably blood, plasma, protein, or other proteins. The food casing is preferably used as artificial sausage casing or cheese casing.

Owner:KALLE AG

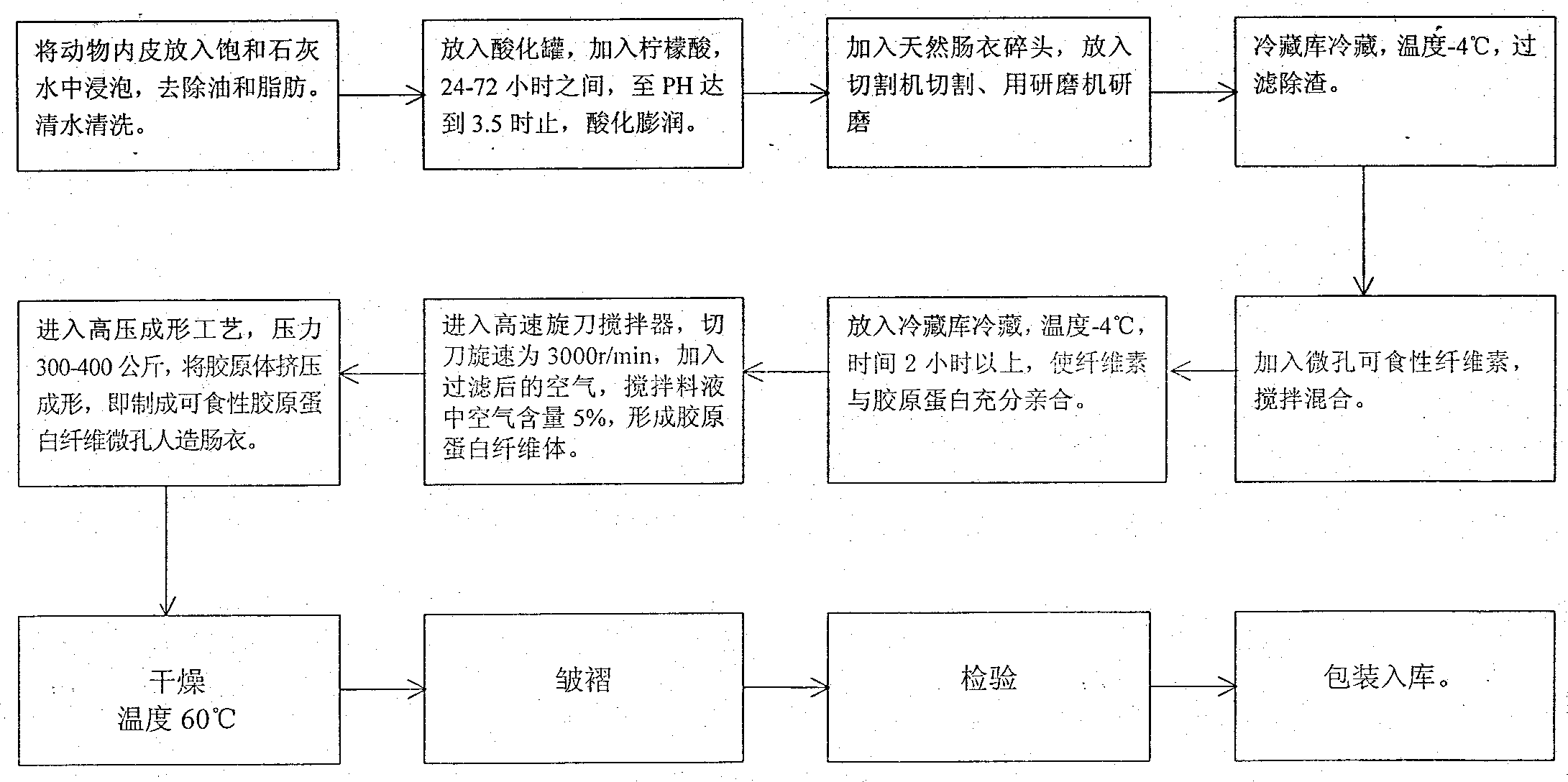

Edible porous artificial sausage casing of collagenous fiber and its production process

The present invention relates to an edible collagen protein fibre microporous artificial sausage skin and its production method. It is characterized by that its raw material contains internal skin ofanimal, microporous edible ellulose, scraps of natural sausage skin, saturated lime water and citric acid, and its advantages lie in that its raw material composition is particular, and its operationis simple and scientific, and its permeability is identical to that of natural sausage skin, and its elasticity is good, so it can be substituted for natural sausage skin, and its cost is low.

Owner:苗文忠

Production of edible artificial sausages coating by enzymolytic collagen protein fibre

InactiveCN101073375ALow shrinkageIncrease productivitySausage casingsProtein foodstuffs working-upFiberHigh pressure

The invention is concerned with a kind of produce method for eatable man made enteric-coated of enzyme hydrolyzed collagen. Dispose animal skin having active albumen using albumen enzyme and hydrolyze reaction to get long exquisite collagen fibre. Wring and smash the fibre, take out under high pressure and mix up to get more differentiating and softer exquisite collagen fibre and long strip of lognitudinal exquisite collagen fibre. Weave exquisite collagen fibre with ring crossing braiding machine and shape with ammonia, dry and mold to get tube-type of slotless enteric-coated with soft and thin wall. The enteric-coated has 50 to 60 percent of weight of enzyme hydrolyzed collagen with enough intensity of pressure without avulsion. It is fit for middle and top grade western-style sausage and high-speed automatic sausage-filling machine with good edibility and taste.

Owner:柳州市宏升胶原蛋白肠衣有限公司

Method of Dyeing a Substrate with a Reactive Dyestuff in Supercritical or Near Supercritical Carbon Dioxide

InactiveUS20080028541A1Promote resultsImprove responseReactive dyesDyeing processProtonationCellulose fiber

The present invention relates to a method of dyeing a substrate with a reactive dyestuff in supercritical or near supercritical carbon dioxide, said substrate being selected from the group consisting of cellulose fibres; modified cellulose fibres; protein fibres; synthetic fibres and any combination thereof, wherein the method comprises dyeing said substrate by contacting the substrate with supercritical or near supercritical carbon dioxide containing a reactive dyestuff and one or more acids in a concentration of at least 0.05 mol. %, calculated on the molar amount of reactive dyestuff that is used in the dyeing method, said reactive dyestuff being a chromophore derivative containing a chromophoric residue and a reactive group, said reactive group comprising a cyclic or heterocyclic aromatic residue that will be protonated under the conditions employed during the contacting, such protonation resulting in enhanced reactivity of the reactive dyestuff towards the plurality of reactive groups contained in the substrate.

Owner:DYECOO TEXTILE SYST

Method for producing large diameter collagen sausage casing with reinforced skeleton structure

InactiveCN101069526AEasy to fillImprove temperature resistanceSausage casingsAnimal proteins working-upFiberUltimate tensile strength

The present invention discloses a large-bore collagen protein casing with reinforced skeleton structure and its production method. It is characterized by that said production method includes the following steps: preparation of skeleton fibre and collage protein fibre, preparation of collagen group and casing formation and treatment. The diameter of the described large-bore collagen protein casing is 50-160mm. it can be used for producing various sausage products.

Owner:钟勇

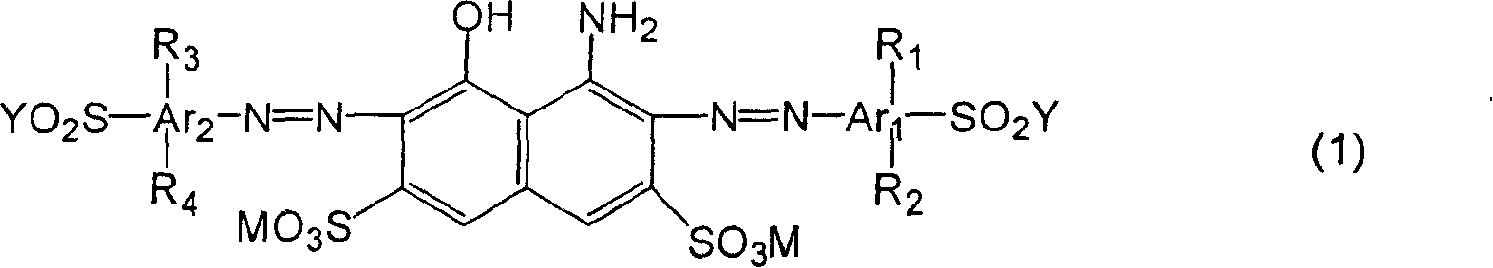

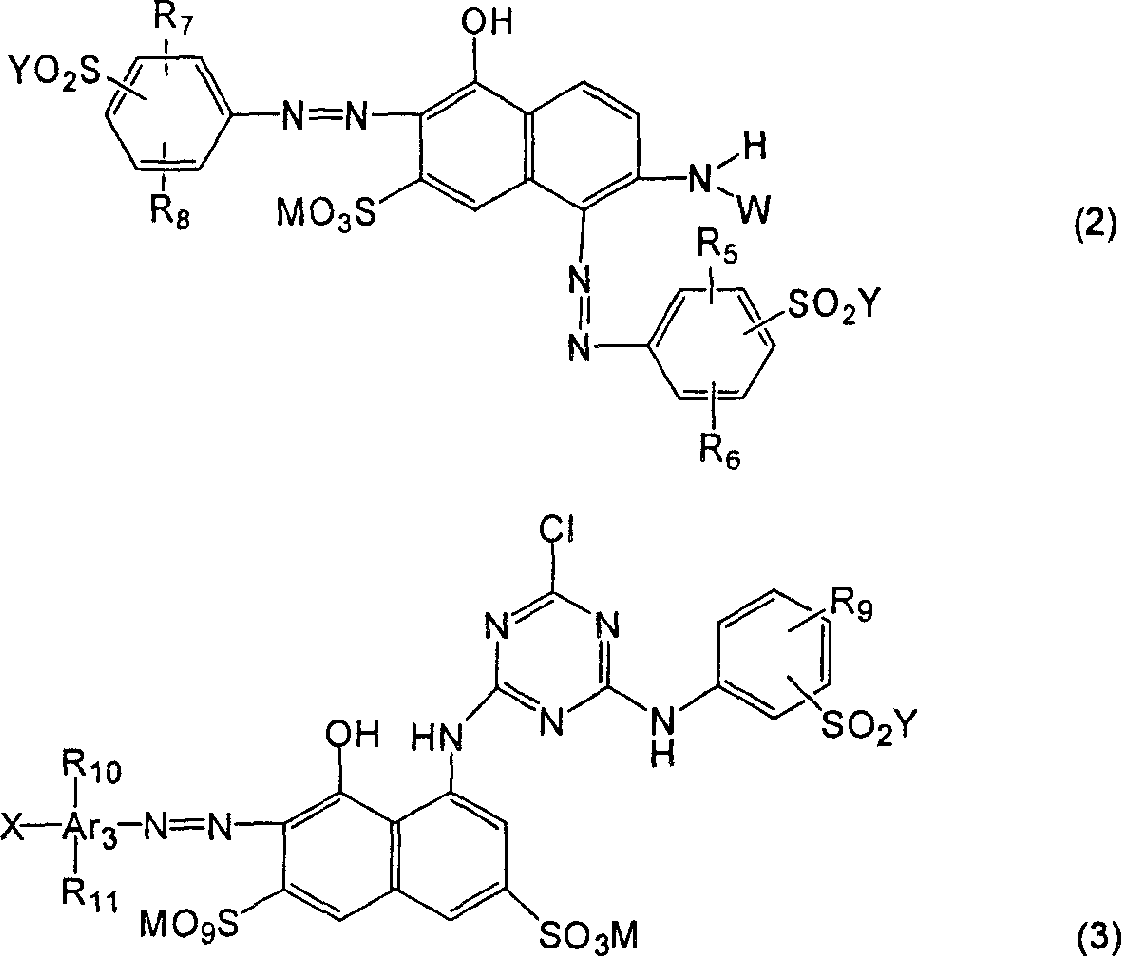

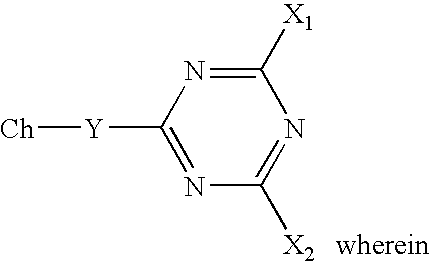

Black reactive dye composition

ActiveCN103992659AImprove washing fastnessImprove solubilityOrganic dyesDyeing processPerspirationCellulose fiber

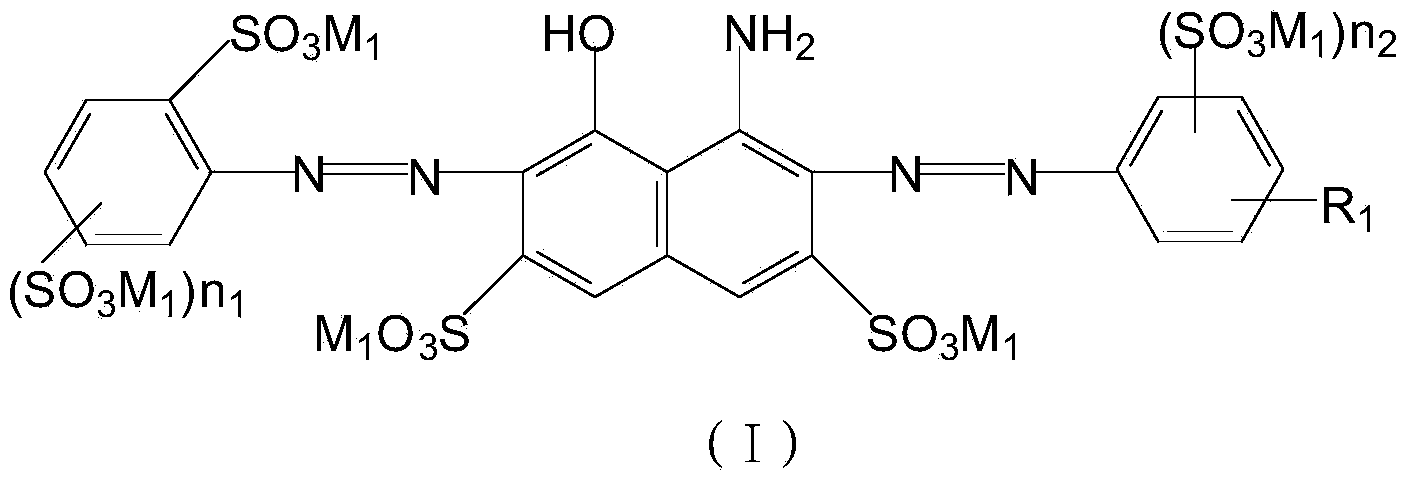

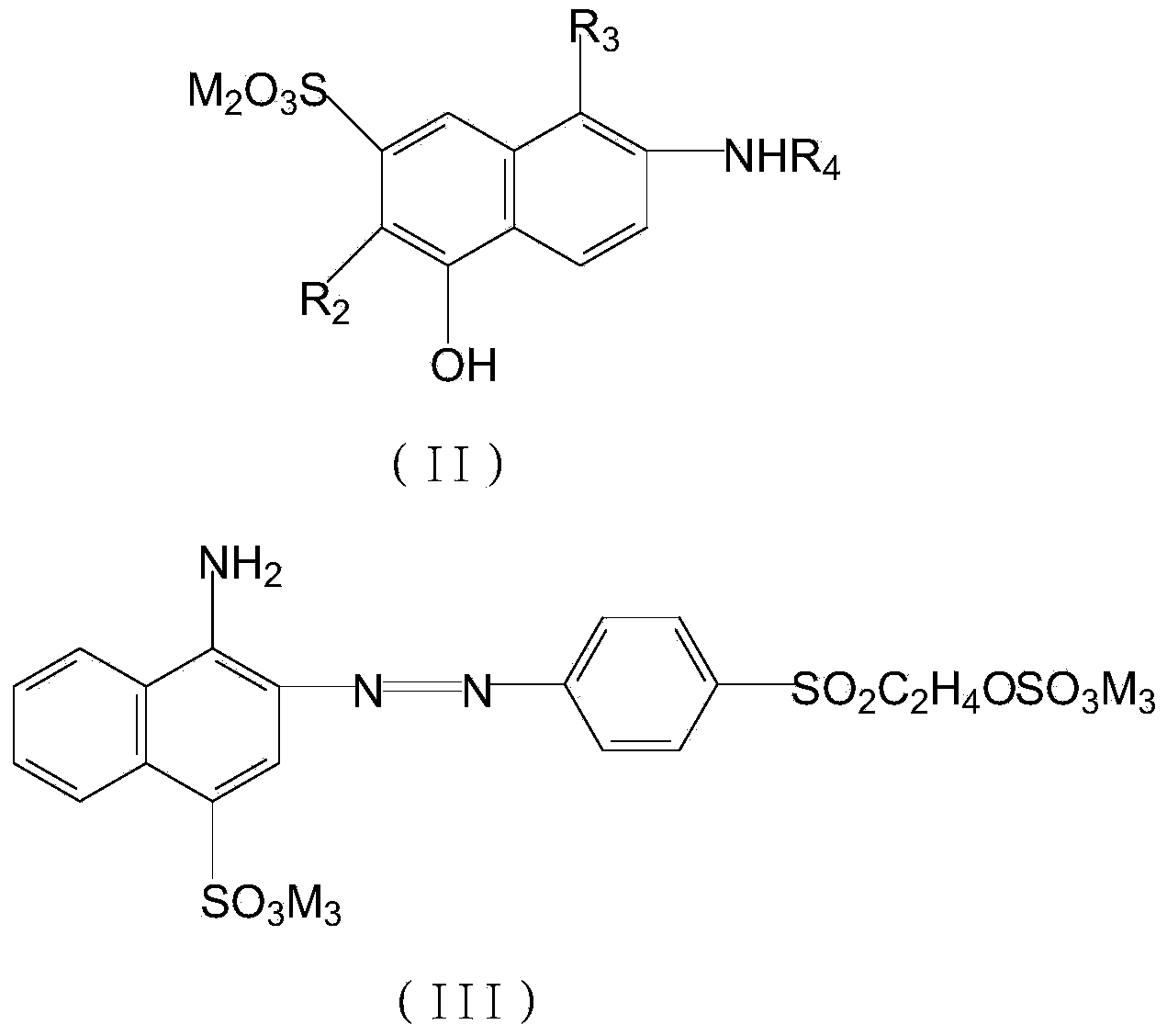

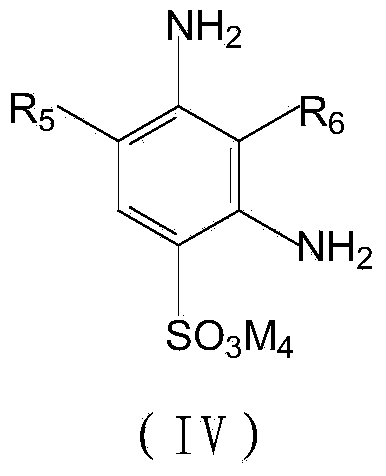

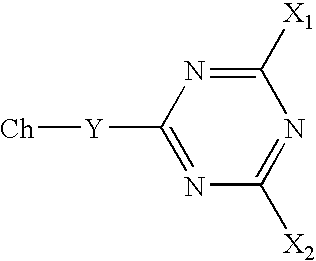

The invention relates to a black reactive dye composition; based on the total weight of the black reactive dye composition, the black reactive dye composition comprises 30-90wt% of a component A, 0-30wt% of a component B, 0-30wt% of a component C, 0-25wt% of a component D and 0-45wt% of an auxiliary; the component A comprises at least one compound represented by the formula (I); the component B comprises at least one compound represented by the formula (II) or a compound represented by the formula (III); the component C comprises at least one compound represented by the formula (IV); and the component D comprises at least one compound represented by the formula (V) or (VI). The black reactive dye composition disclosed by the invention is applied to printing and dyeing cotton, artificial cotton, fibre, regenerated fibre or textile fabrics thereof or printing and dyeing polyamide fibre, cellulosic fibre, protein fibre or textile fabrics thereof, is particularly applied to printing and discharge-printing artificial cotton, and has excellent washing fastness and perspiration fastness, and therefore, fabrics have good feel.

Owner:ZHEJIANG RUIHUA CHEM

Method of Dyeing a Substrate With a Reactive Dyestuff in Supercritical or Near Supercritical Carbon Dioxide

InactiveUS20080005854A1Easy to fixOutstanding washfastness and fastness to rubbingFibre treatmentReactive dyesCellulose fiberEthyl acetate

The present invention relates to a method of dyeing a substrate with a reactive dyestuff in supercritical or near supercritical carbon dioxide, said substrate being selected from the group consisting of cellulose fibres, modified cellulose fibres, protein fibres and of synthetic fibres, or any combination thereof, wherein the method comprises the subsequent steps of: pre-treating the substrate by wetting the substrate with a fluid medium containing at least 10 wt. %, preferably at least 40 wt. % of one or more organic hydrogen bond acceptor compounds selected from the group consisting of C1-C6 alkanols, dimethyl sulfoxide, dimethylformamide, acetone, butan-2-one, dimethyl ether, methyl acetate and ethyl acetate; dyeing the substrate by contacting the pre-treated substrate with supercritical or near supercritical carbon dioxide containing a reactive dyestuff.

Owner:DYECOO TEXTILE SYST

Synthetic fiber containing animal hair protein and manufacturing method thereof

InactiveCN1524980AIncrease elasticityGood hygroscopicityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsInorganic ChemicalPolyvinyl alcohol

The invention discloses a synthetic fiber containing animal hair protein, composed of protein and poval, where the protein is a separation one extracted from the animal hair and the content of the protein in the synthetic fiber is 1%-25% or 40%-90%. It also discloses a method to make the synthetic fiber. It uses not only the animal hair but also human broken hair as raw material, thus further enlarging the raw material source of making fiber, and the made fiber does not contain unnecessary inorganic chemical composition and will not produce environmental pollution in the making course.

Owner:李官奇

Process for removing formaldehyde from synthetic protein fibres

InactiveCN1376817AAlso has a bleaching effectLow residual formaldehydeCellulose/protein filament chemical after-treatmentFiberSynthetic protein

A process for removing formaldehyde from synthetic protein fibres to prevent the damage of residual formaldehyde to human body includes such steps as preparing 40% aqueous solution of sodium hydrogensulfite, washing the acetalized protein fibres with water, immersing in said aqueous solution at 40-60 deg.C for 5-10 min, water washing and centrifugal drying. Its advantages are high effect, simpleprocess, and bleaching action.

Owner:胡宗善 +1

Preparing method of medical nerve transplant containing silk element

ActiveCN100382772CPromote regenerationGood tissue compatibilityAnthropod material medical ingredientsPeptide/protein ingredientsFiberNerve graft

The medical nerve graft is formed from catheter or catheter and fibre scalfold, and is characterized by that at least one of catheter and fibre scalfold contains silk bambycin protein component. Its preparation method includes the following steps: making natural silk into silk bambycin protein fibre; preparing said silk bambycin protein fibre into catheter containing silk bambycin protein, and combining the catheter and fibre scalfold.

Owner:NANTONG UNIVERSITY

Method for inhibiting and eliminating fluorescence on textile product

InactiveCN101245556AInhibit or eliminate fluorescent substancesStrong damageVegetal fibresAnimal fibresPolymer scienceFluorescence

The invention relates to a method for restraining and eliminating fluorescence of a textile product, comprising a chlorine dioxide fluorescence-eliminating method, a chlorine dioxide / sodium chlorite fluorescence-eliminating method and an acetyhydroperoxide fluorescence-eliminating method; the methods can effectively restrain or eliminate the fluorescence on the textile product made of cellulose fibre or protein fibre, and the processed textile product has high intensity and little damage; the method not only can be used for eliminating the fluorescence of the textile product, but also can be used for stripping processing of colored textile products.

Owner:DONGHUA UNIV

Woolen fibre water-penetrated non-fabric sanitary material and its production

ActiveCN1896358AStrong liquid absorptionImprove liquid absorption performanceNon-woven fabricsWAS PROTEINProduction line

The present invention discloses a wool fibre spunlaced nonwoven sanitary materials that is composed of 70-100 weight units of carbonized wool fibre or surface degreased and chemical modified wool fibre and 0-30 weight units of natural fibre, chemical fibre or synthetic fibre and processed on the spunlaced nonwoven product line. The weight of unit area is 30-200g / m2. The provided wool fibre spunlaced nonwoven sanitary materials have good liquid absorbency and biocompatibility, has no stimulate on the skin and can disperse water and skin caring liquid evenly. The wool fibre is protein fibre with liquid absorbency, biocompatibility and skin caring function. Materials for beauty mask can be produced by adding carbonized or other specially treated wool fibres in the production and can be applied to beauty culture or medicine field.

Owner:XINLONG HLDG GROUP

Method for producing protein fibre filament yarn with PVA or PAN as carrier

InactiveCN101173373ASimple processLess investmentMonocomponent protein artificial filamentArtificial filament heat treatmentFiltrationEngineering

The invention belongs to a production method of protein fiber filaments with PVA or PAN as the carrier. Composed of winding processes, the spinning stock solution is spun and drawn on a piece of equipment through a series of processes to produce fully drawn yarns. Its advantages are short process, small investment and simple equipment.

Owner:SHAOYANG TEXTILE MACHINERY

Technique for producing chromonema, yarn

InactiveCN1462825AReduce pollutionShorten the production cycleLiquid/gas/vapor yarns/filaments treatmentBobbinPetrochemical

A technology for preparing the dyed fibres (including natural fibre, protein fibre, chemical fibre, or artificial fibre), or yarn includes fusing the polyester chips, drawing-spinning to become filaments, preheating, boarding, winding on steel bobbin with dense through holes, and dyeing by putting the bobbin in dyeing machine. Its advantage is high dyeing quality.

Owner:金国周

Production of edible artificial sausages coating by enzymolytic collagen protein fibre

InactiveCN100551253CLow shrinkageIncrease productivitySausage casingsProtein foodstuffs working-upBiotechnologyFiber

The invention discloses a method for making edible artificial sausage casings by enzymatically decomposing collagen fibers. The method successfully uses protease to moderately hydrolyze animal leather with protein activity to obtain delicate long collagen fibers, and through grading Grinding, high-pressure spinning, mixing and other processing steps make the collagen fibers more subdivided and softer, and obtain longitudinal strips of collagen fibers. The collagen fibers are braided and shaped by a circular cross braiding machine, and then shaped with ammonia gas. After drying and qualitative treatment, it is made into seamless, transparent, thin and soft tubular casings. The casings produced by this method mainly contain 50-60 parts by weight of collagen protein and have sufficient compressive strength. When used in sausage production, There will be no tearing phenomenon, and good edibility and palatability are obtained. The performance of the casing is especially suitable for the use of medium and high-end western-style sausages and high-speed automatic sausage filling machines.

Owner:柳州市宏升胶原蛋白肠衣有限公司

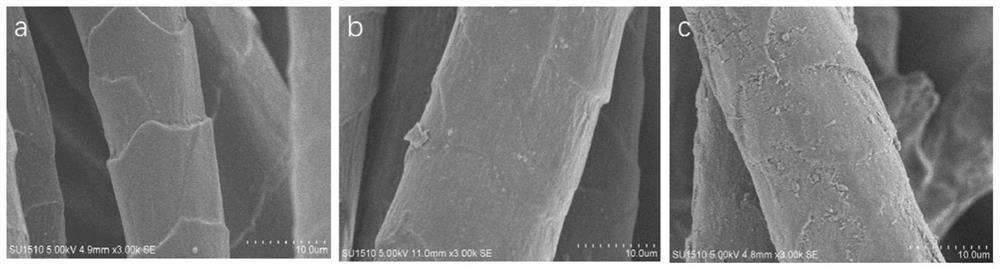

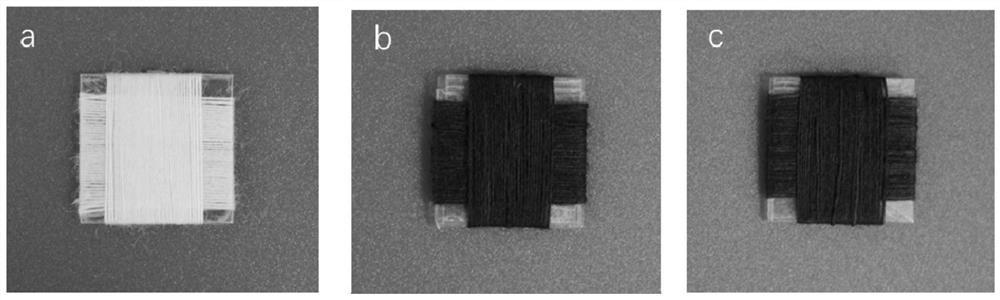

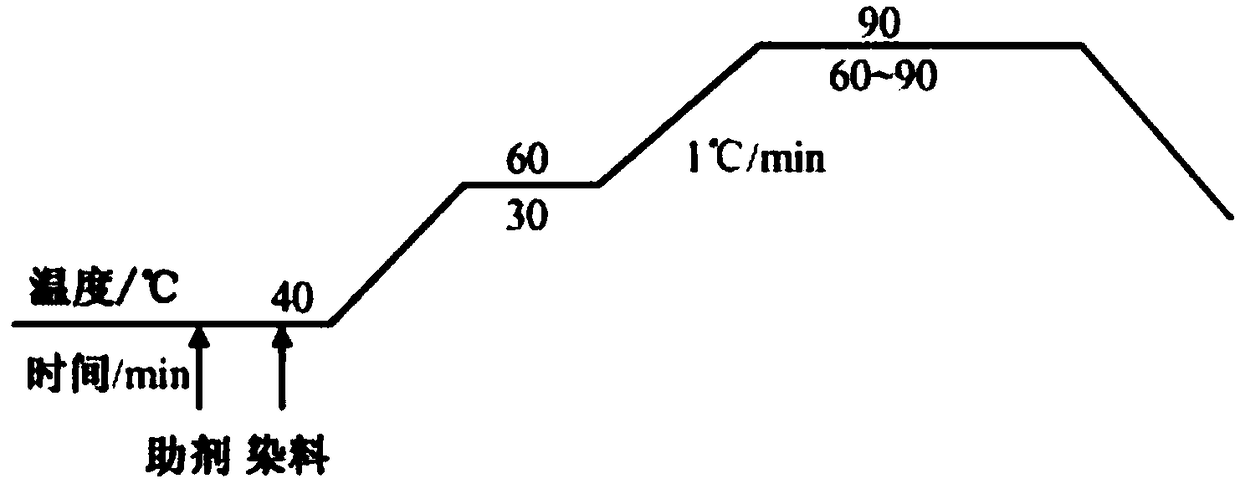

Biological enzymatic dyeing method for improving wool fiber strength

ActiveCN112647317AHigh strengthImprove dyeing effectPhysical treatmentBiochemical treatment with enzymes/microorganismsPolymer scienceEngineering

The invention discloses a biological enzymatic dyeing method for improving the wool fiber strength, and belongs to the technical field of textile material modification. The characteristics that protein fiber macromolecules contain a large number of active groups such as hydroxyl groups, amino groups and carboxyl groups and easily react with polyphenol pigments formed by enzyme catalyzed phenolic compounds to form covalent binding are utilized, low-temperature dyeing of wool fibers is achieved, and meanwhile, the fiber strength is improved. The biological enzymatic dyeing method for improving the wool fiber strength is mild in operation condition and easy to control, wool fiber dyeing is safe, environmentally friendly and efficient through biological enzymes at present when environmental protection is increasingly emphasized, and the biological enzymatic dyeing method has a long-term development prospect.

Owner:JIANGNAN UNIV

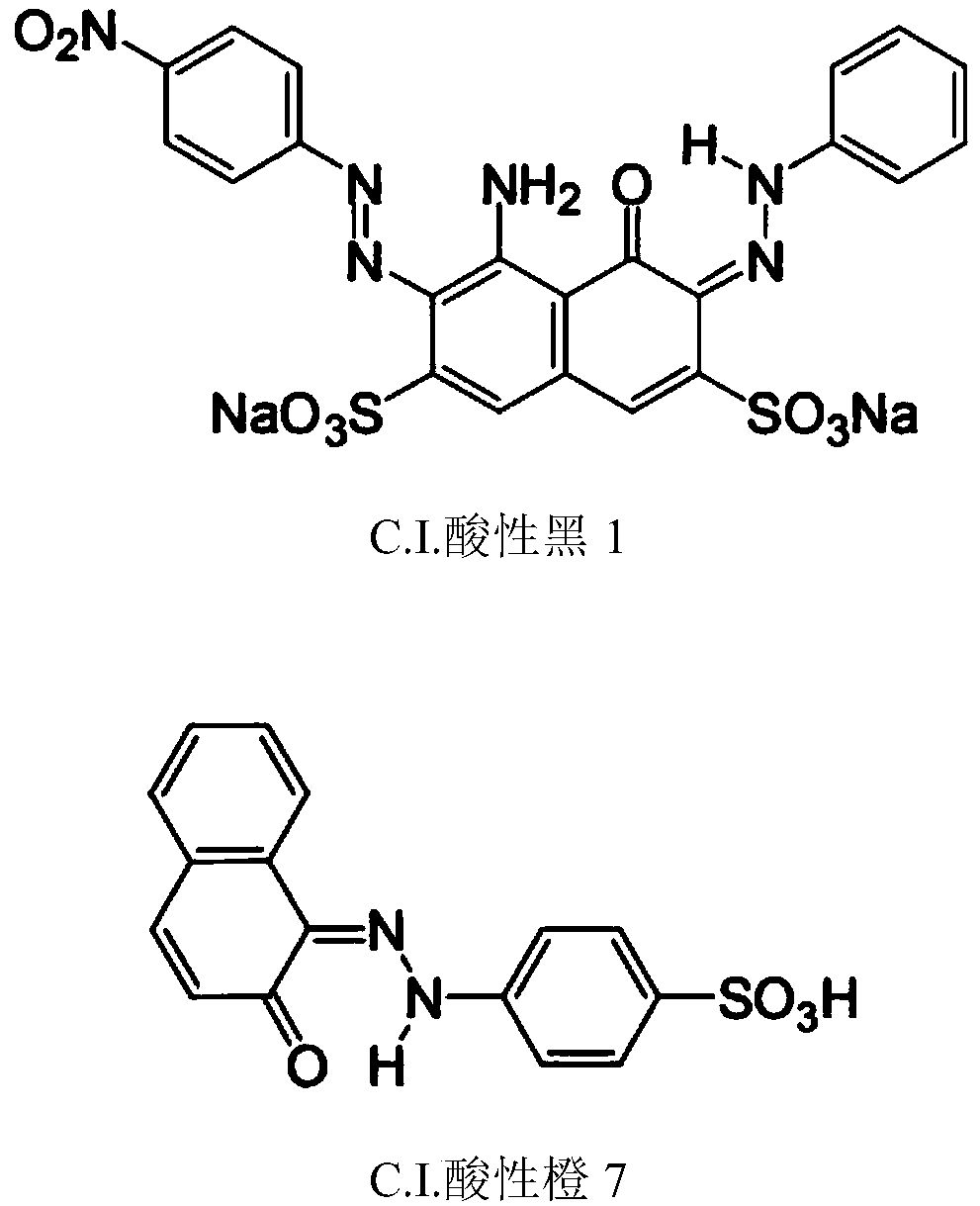

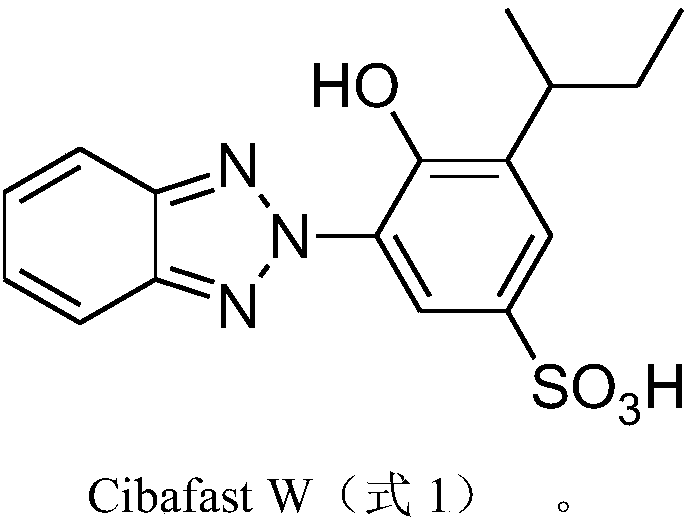

Highly sun-proof type acid black dye composition

ActiveCN109233336AGood dyeing rateHigh fastnessOrganic dyesDyeing processUltraviolet lightsHydroxy compound

The invention discloses a highly sun-proof type acid black dye composition. The composition is prepared from the following components in parts by weight: 7 parts of a component A, 3 parts of a component B, 1-6 parts of a component C, wherein the component A is C.I.acid black 1, the component is C.I.acid orange 7, and the component C is any one of Cibafast W, 2-hydroxyl-4-methoxy-5-sulfoacid diphenyl ketone, and an ultraviolet light absorber V. The mixing synergism principle of the component A, the component B and the component C is utilized; and the obtained black dye composition has a good dyeing rate and good sun-proof firmness, and is very suitable for dyeing and printing process of protein fibres.

Owner:浙江金塔克斯科技有限公司

Fish bait for carp and preparation method thereof

InactiveCN101711550AReduce manufacturing costCreate pollutionAnimal feeding stuffOther angling devicesEcological environmentCarp

The invention relates to fish bait for the carp and a preparation method thereof. The fish bait comprises the following components: sweet potato powder, euphausia powder, pure wheat protein fibre, additive and water and the weight ratio of cultivated carp to sweet potato powder, euphausia powder, pure wheat protein fibre, additives and water is 1-4:0.3-0.8:0.5-2:0.2-0.9:0.1-1:2-4. The invention adopts various plants as raw materials, contains no harmful additive and can not cause pollution to the ecological environment of the water body; and the technology is simple, the production cost of the raw materials is low, and the fish bait is suitable to be used by general fishing enthusiasts. The invention adopts the strawberry jam as the additive and has strongly fragrant smell and the carp likes sweet taste so that the fish bait is a powerful attractant to the carp, and the hooking rate of the carp can be greatly improved.

Owner:陶义

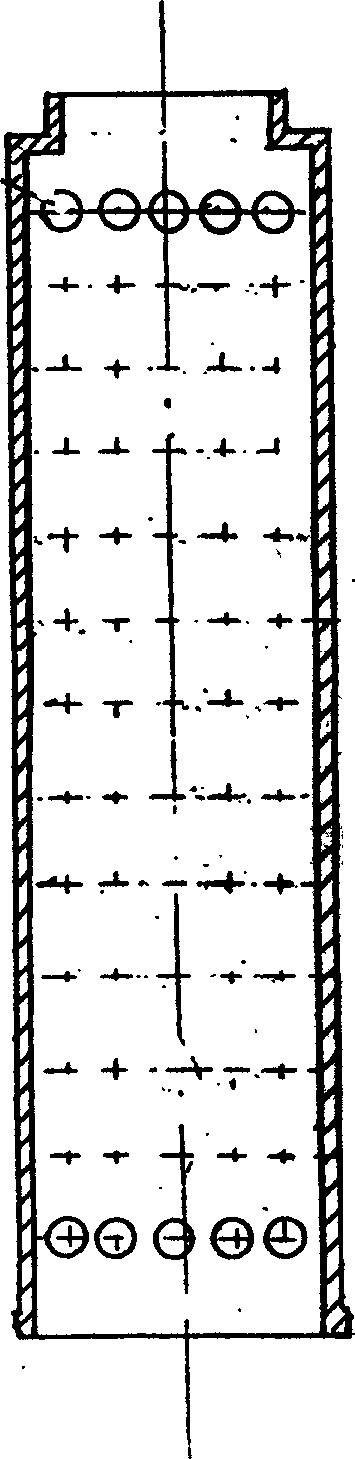

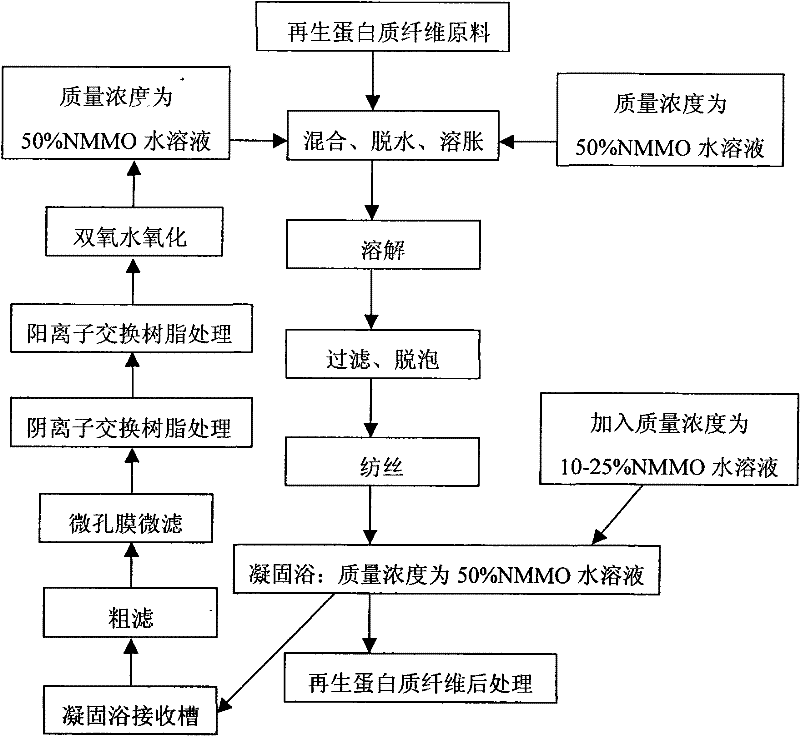

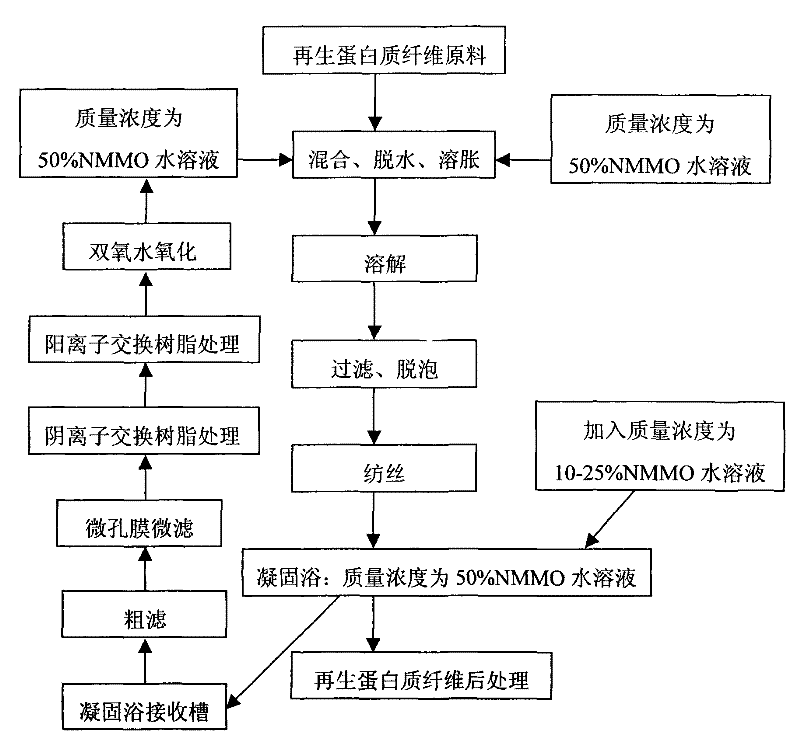

Recovery method of N-methylmorpholine oxide solvent in process of generating regenerated protein fibre by solvent method

InactiveCN101942713BExtend your lifeAvoid generatingArtificial filament recoveryTextile/flexible product manufactureRecovery methodFiber

The invention relates to a recovery method of an N-methylmorpholine oxide (NMMO) solvent in a process of generating regenerated protein fibre by a solvent method in a spinning technology. The technical scheme of the invention is designed as follows: NMMO aqueous solution with the mass concentration of 50% is taken as a coagulating bath of the regenerated protein fibre; the circulation of the coagulating bath is optimally controlled so that the mass concentration of the coagulating bath of the NMMO aqueous solution in a coagulating bath-loading container is controlled to be 50%; and multiple impurities in recovery liquid, namely a coagulating bath solution, are removed through rough filtration, microporous membrane microfiltration, anion exchange resin treatment, cation exchange resin treatment and hydrogen peroxide oxidization, thereby achieving the recovery of the NMMO solvent.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Synthetic fiber containing animal hair protein and manufacturing method thereof

InactiveCN1245542CIncrease elasticityGood hygroscopicityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsBiotechnologyEngineering

The invention discloses a synthetic fiber containing animal hair protein, composed of protein and poval, where the protein is a separation one extracted from the animal hair and the content of the protein in the synthetic fiber is 1%-25% or 40%-90%. It also discloses a method to make the synthetic fiber. It uses not only the animal hair but also human broken hair as raw material, thus further enlarging the raw material source of making fiber, and the made fiber does not contain unnecessary inorganic chemical composition and will not produce environmental pollution in the making course.

Owner:李官奇

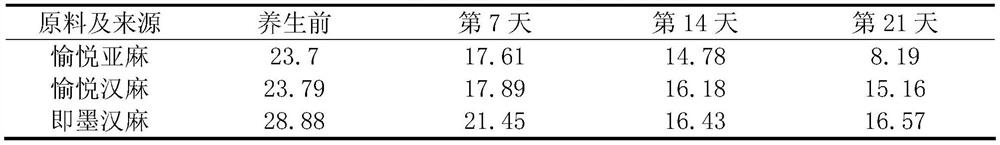

Protein fiber/jute fiber blended fabric and production process thereof

ActiveCN113046878ASoft touchGuaranteed strongBiochemical treatment with enzymes/microorganismsDyeing processYarnPolymer science

The invention relates to the technical field of blended fabrics, in particular to a protein fiber / jute fiber blended fabric. The protein fiber / jute fiber blended fabric is a protein fiber / jute fiber blended dyed yarn prepared by performing pretreatment, neutralization cleaning, wool mixing, combing and drawing on protein fibers to obtain wool tops and performing health maintenance, carding, combing and drawing on jute fibers to obtain jute strips, and then performing combing, drawing, rough yarn spinning, spun yarn spinning, dyeing and finishing; and then the obtained protein fiber / hemp fiber blended dyed yarn is woven to obtain gray fabric, then the gray fabric is subjected to after-treatment to obtain the fabric, and the gram weight of the fabric is 180-400 g / m<2>. The invention further discloses a production process of the protein fiber / jute fiber blended fabric. The fabric manufactured through the production process has the health-care functions of resisting bacteria, preventing and inhibiting bacteria, protecting skin, building body, moistening skin and the like, and is high in fabric strength, smooth and soft in cloth cover, good in moisture absorption and breathability, rich in luster, good in ultraviolet resistance, good in bacteria prevention and inhibition performance, unique in appearance, and soft and hazy in colored light.

Owner:青岛奥洛思新材料有限公司

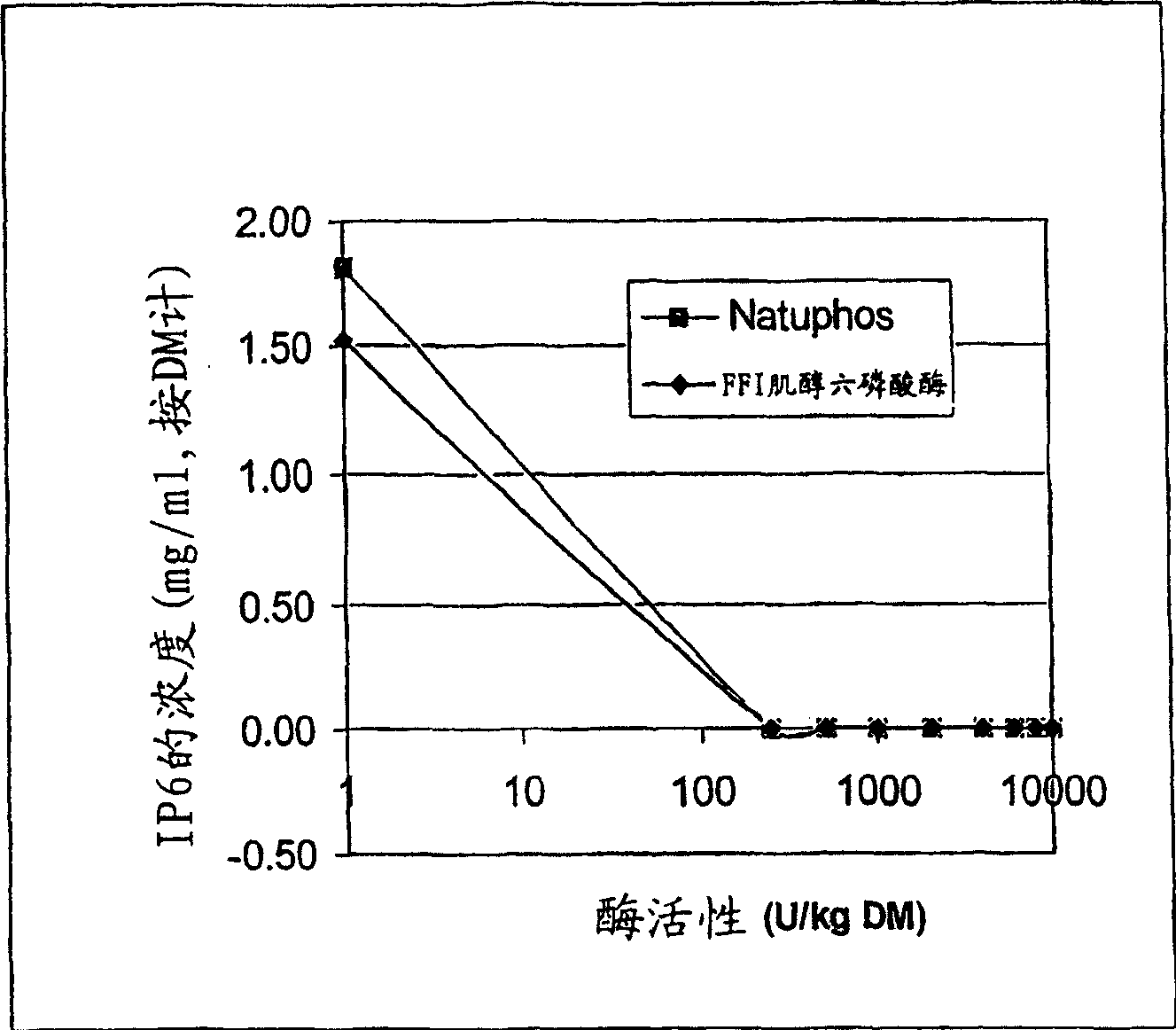

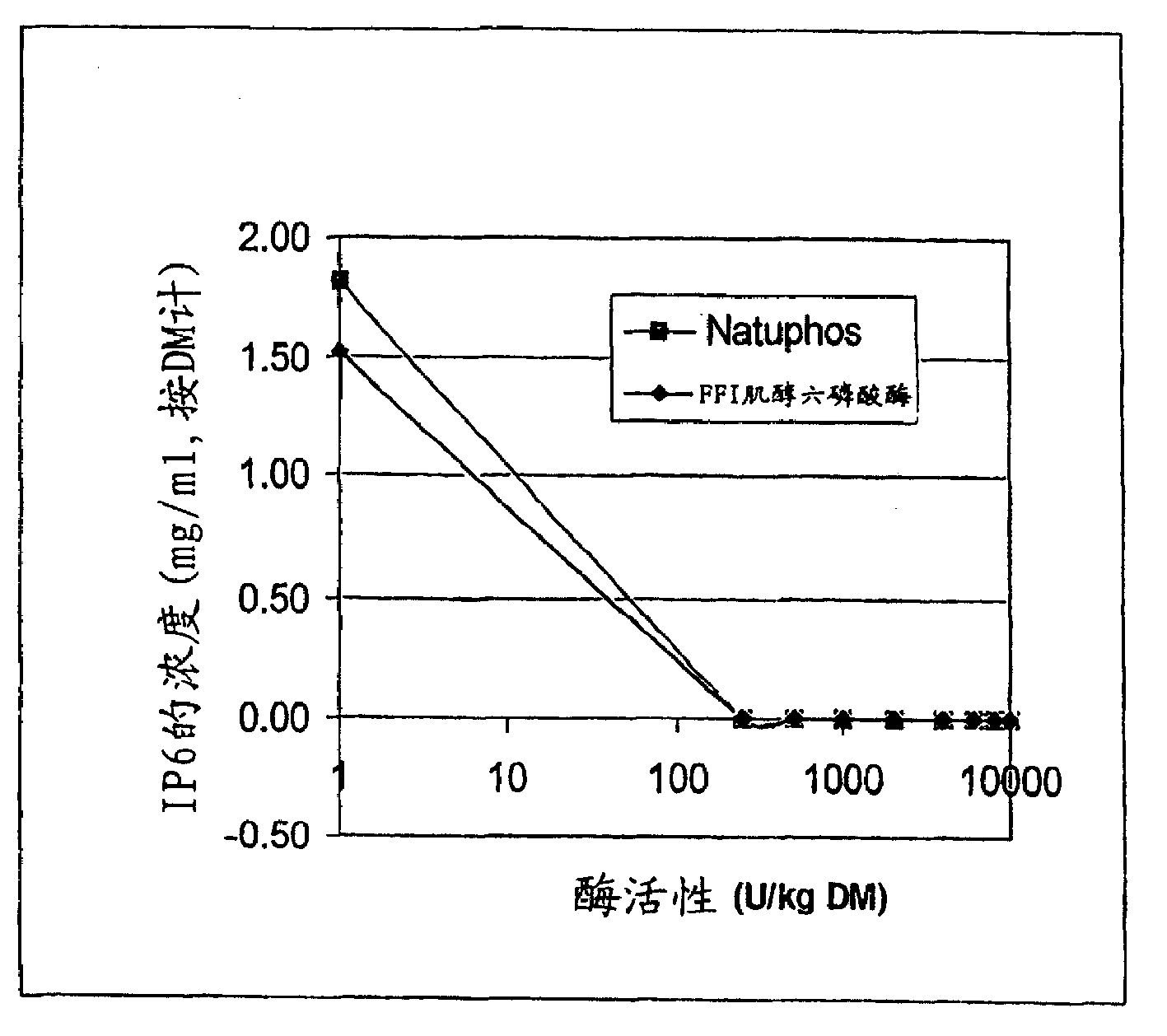

Fractionation and processing of oilseed meal

The present invention relates to a process for the aqueous extraction, fractionation and enzymatic treatment of oilseed materials to generate valued products with no significant low value by-product or waste streams. In particular, the fractionation scheme generates a protein-fibre feed ingredient principally for use with ruminant animals and a second dephytinized high protein fraction. The dephytinized high protein fraction has value as feed ingredient for a variety of species of animals.

Owner:UNIVERSITY OF SASKATCHEWAN

Dyeing method of protein fiber yarn

InactiveCN113026388AImplement the dye methodImprove dyeing effectBiochemical treatment with enzymes/microorganismsDyeing processYarnTetrafluoroborate

The invention provides a dyeing method of protein fiber yarns. The dyeing method comprises the following steps that fresh bryophyllum pinnatum leaves are adopted as a raw material to prepare powder through drying, the powder is added into deionized water, and extracting is conduced to obtain a basic dyeing solution; the protein fiber yarn is washed with a mixed solution of hydrogen peroxide and sodium silicate, then bleaching liquid treatment and ozone treatment are performed, maltose partial grafting treatment, catechol oxidase catalytic oxidation treatment, 1-aminopropyl-3-methylimidazolium tetrafluoroborate dipping treatment and drying are performed in sequence, and pre-treated protein fiber yarn is obtained; and finally, the pretreated protein fiber yarn is added into the basic dyeing solution, dyeing and post-treatment are conducted, and then the dyeing method of the protein fiber yarn can be achieved. Natural plant components are used for dyeing protein fiber yarns such as wool fibers, soybean protein fiber yarns and casein fiber yarns and the like, and the method is green, environmentally friendly and good in dyeing effect.

Owner:深圳市金绒达新材料科技有限公司

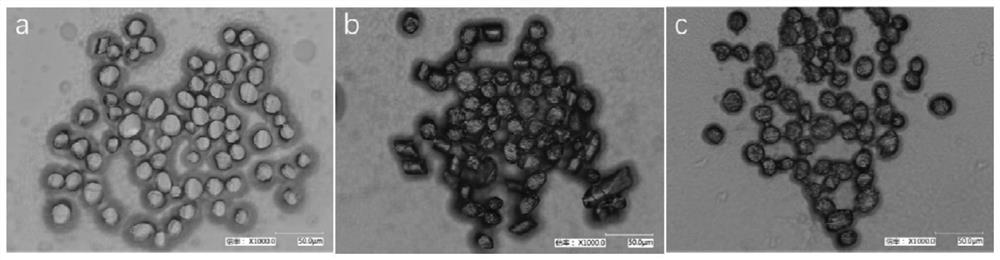

Microparticles comprising cellulose nanocrystals aggregated with proteins and cosmetic use thereof

PendingCN114364365AEnsure Structural IntegrityGood moisturizing effectCosmetic preparationsPowder deliveryPolymer scienceOil emulsion

The invention provides protein cellulose microparticles. These microparticles comprise cellulose nanocrystals and one or more peptides, one or more proteins, or mixtures thereof, wherein the nanocrystals aggregate with the peptides and / or proteins to form microparticles. In embodiments, the microparticles comprise silk fibroin, and advantageously, the silk fibroin is hydrophobic and lipophilic. The invention also provides cosmetic products comprising these microparticles. In advantageous embodiments, these cosmetic articles comprise a water-in-oil emulsion or a lipophilic medium. Finally, the invention also provides a method for preparing the microparticles.

Owner:ANOMERA INC

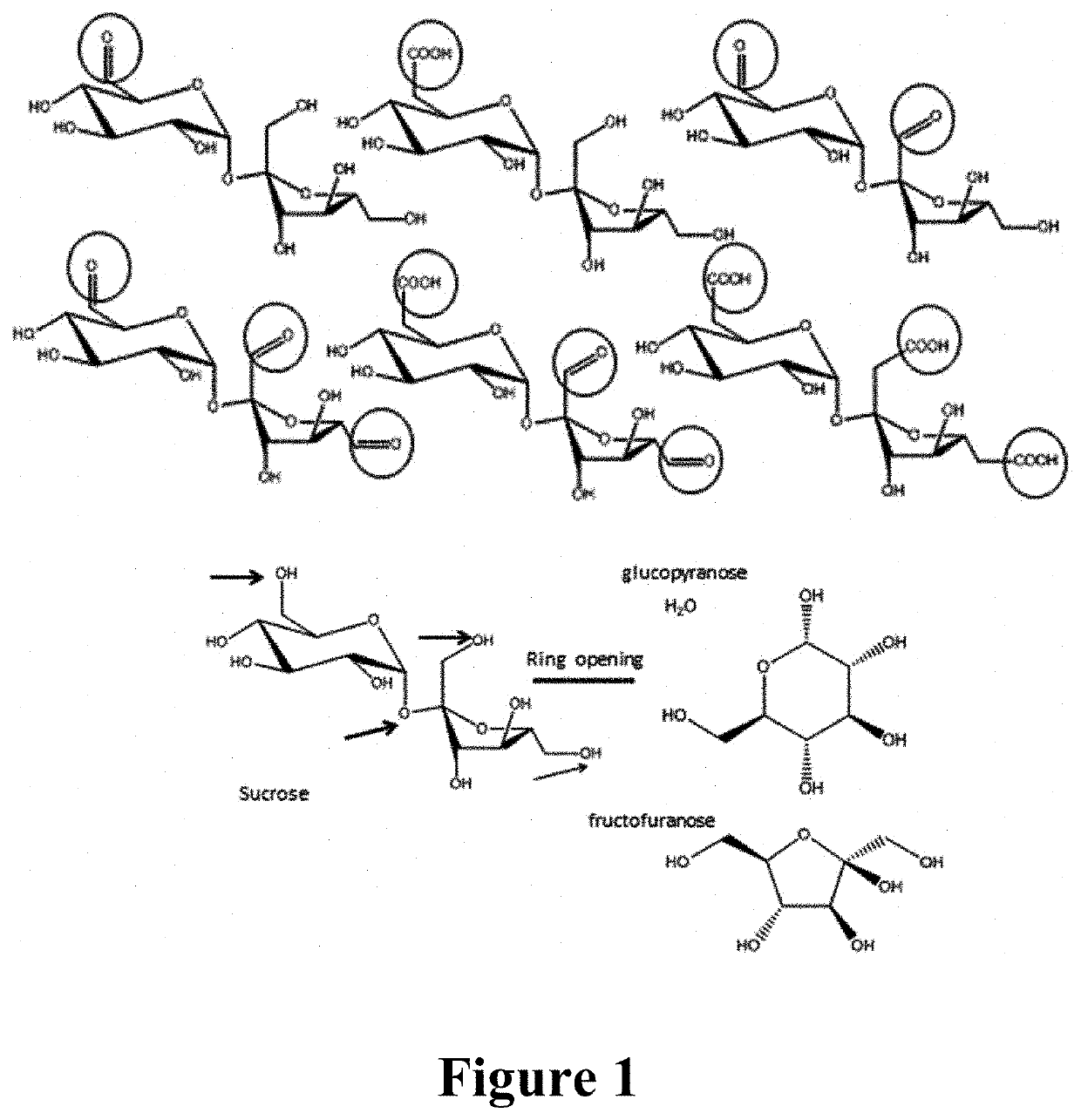

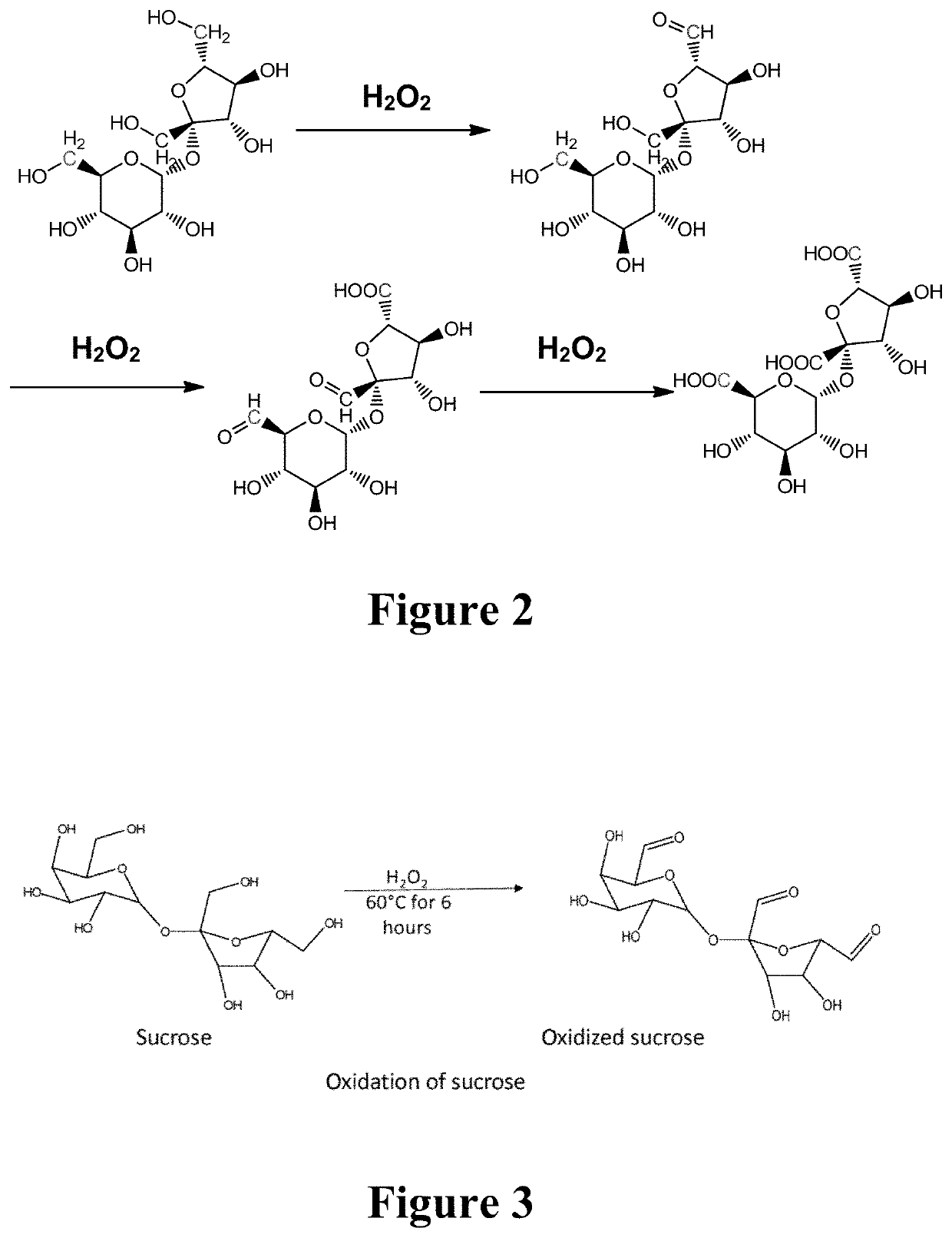

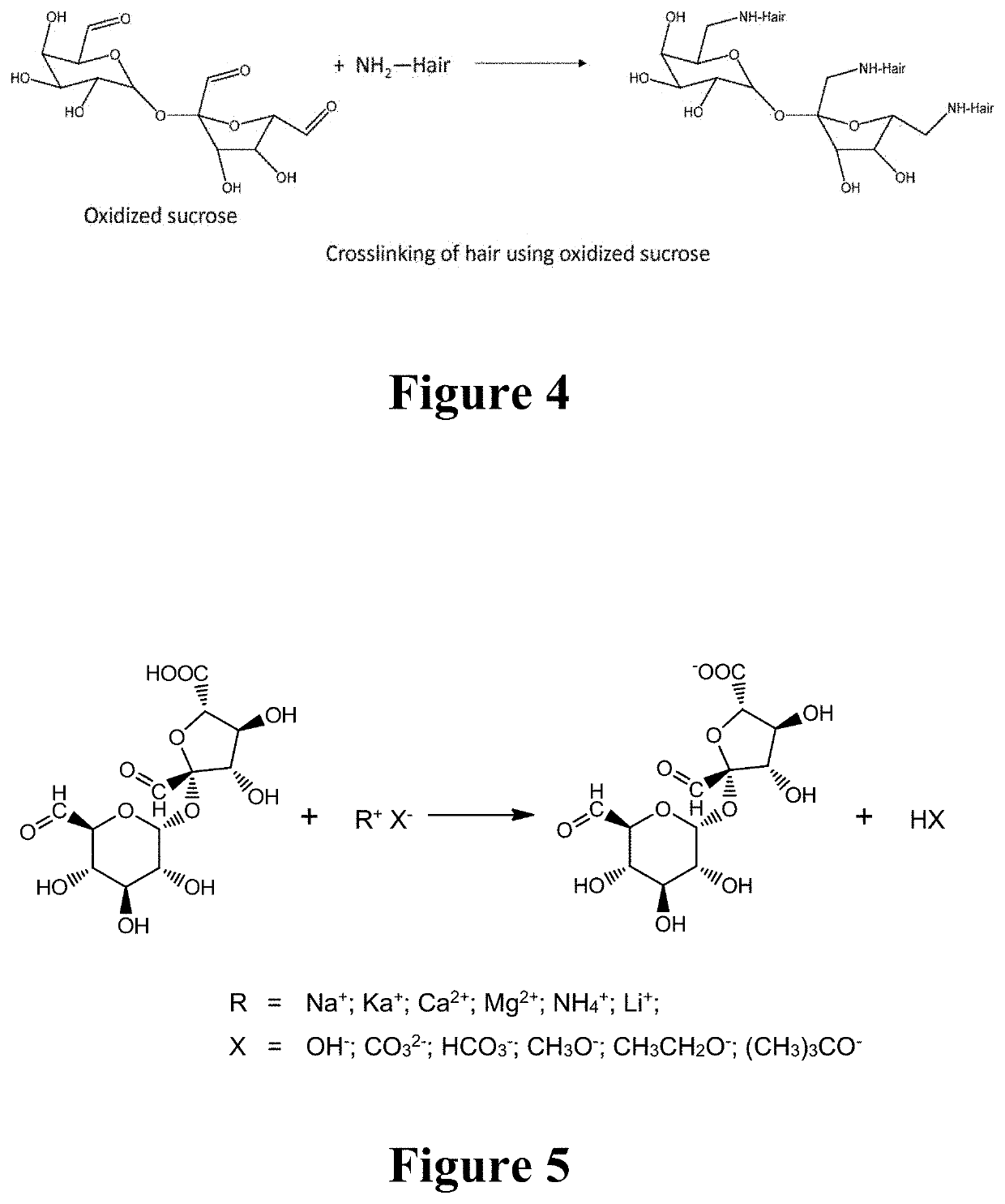

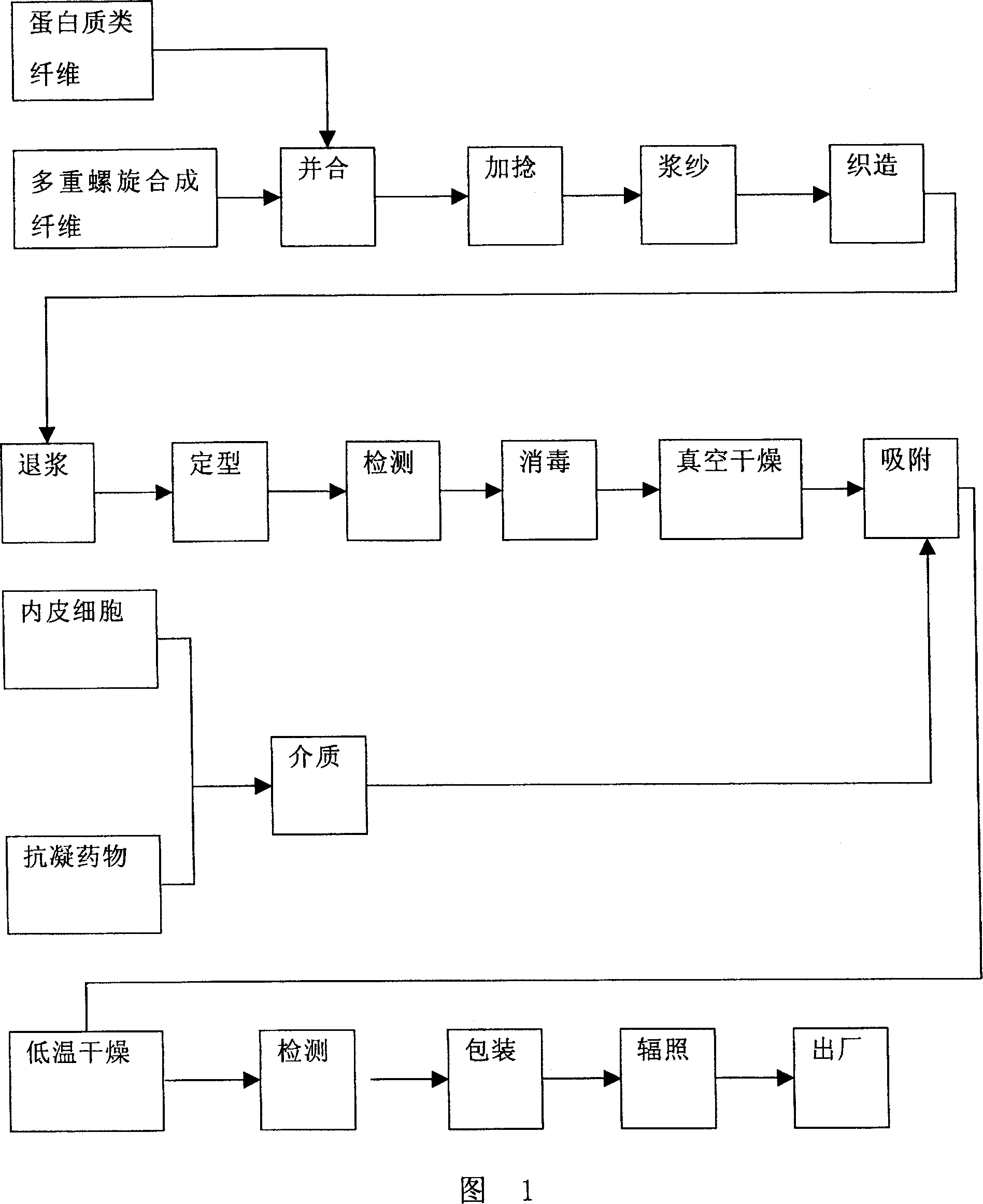

Residual soy flour sugars as crosslinkers for enhancing mechanical performance of protein fibers

ActiveUS20200207924A1Stiffness longLong straightnessCosmetic preparationsHair cosmeticsPolymer scienceProtein molecules

Disclosed is a method of crosslinking protein fibers, including wool fibers, by (i) providing a crosslinking agent including an oxidized sugar mixture having a plurality of different oxidized sugars of different molecular lengths and having at least two aldehyde groups (e.g., oxidized soy flour sugars); and (ii) infiltrating a plurality of non-crosslinked protein fibers with the crosslinking agent under conditions effective to cause protein molecules contained in the non-crosslinked protein fibers to become crosslinked. This method yields a population of crosslinked protein fibers, where the protein molecules of the non-crosslinked protein fibers include amine groups that react with the aldehyde groups of the oxidized sugars to achieve the crosslinking of the protein molecules to yield the crosslinked protein fibers.

Owner:CORNELL UNIVERSITY

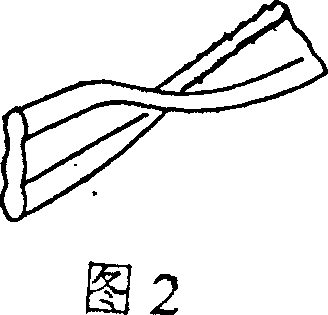

Artificial blood vessel blended by utilizing natural bent synthetic fibre and protein fibre and its production method

InactiveCN100350885CHigh affinityAffinity is naturalMelt spinning methodsWoven fabricsPolyesterTissue Compatibility

The present invention relates to artificial organ, in particular it relates to a natural flexible synthetic fibre and protein fibre blended artificial blood vessel with good biological modification potential energy. The natural flexible synthetic fibre is the fibre made up by using two polyester chip with different contraction rates through the processes of mixing, melting and spinning and having cyclic tortuous property, so that it has natural flexible property. The production process of said invented artificial blood vessel made up by blending the above-mentioned natural flexible synthetic fibre and protein fibre is similar to that of other general artificial blood vessel, but said invented artificial blood vessel has higher strength, good vessel wall permeability and good tissue compatibility.

Owner:无锡莱福纶生物材料有限公司

Woolen fibre water-penetrated non-fabric sanitary material and its production

ActiveCN1896358BStrong liquid absorptionImprove liquid absorption performanceNon-woven fabricsWAS PROTEINProduction line

The present invention discloses a wool fibre spunlaced nonwoven sanitary materials that is composed of 70-100 weight units of carbonized wool fibre or surface degreased and chemical modified wool fibre and 0-30 weight units of natural fibre, chemical fibre or synthetic fibre and processed on the spunlaced nonwoven product line. The weight of unit area is 30-200g / m<2>. The provided wool fibre spunlaced nonwoven sanitary materials have good liquid absorbency and biocompatibility, has no stimulate on the skin and can disperse water and skin caring liquid evenly. The wool fibre is protein fibre with liquid absorbency, biocompatibility and skin caring function. Materials for beauty mask can be produced by adding carbonized or other specially treated wool fibres in the production and can be applied to beauty culture or medicine field.

Owner:XINLONG HLDG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com