Dark black active dyestuff having high colour fixing rate

A technology of reactive dyes and three primary colors, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of high chroma of dyeing residue, affecting economic benefits, dye residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

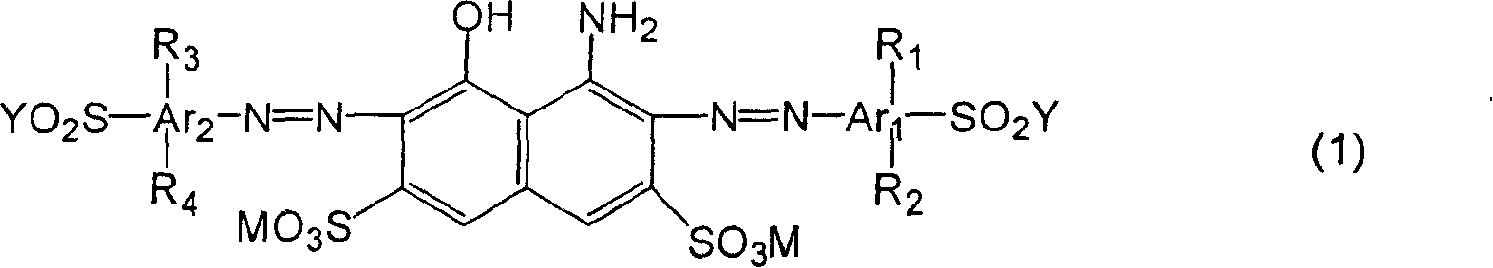

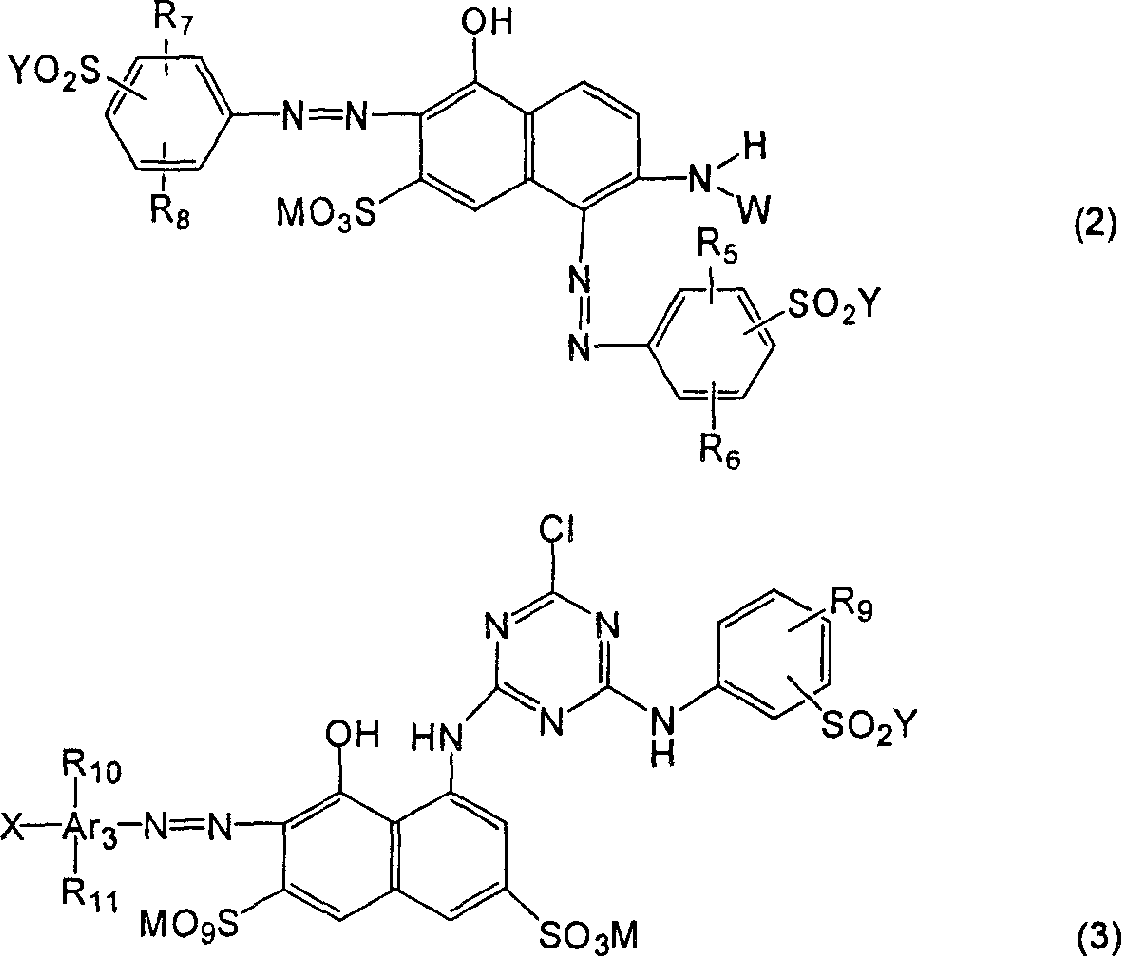

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Mix 0.1mol of para-ester (compound 01) and 0.13mol of sulfuric acid, add 350g of ice-water mixture, beat for 30min, and drop 30% NaNO from below the liquid surface at 0-5°C 2 Solution 0.1mol, keep NaNO during dropwise addition and reaction 2 excess. After diazotization to the end point, excess NaNO 2 Destroy with sulfamic acid.

[0079] Add 0.1 mol of 1-amino-8-naphthol-3,6-disulfonic acid (H acid) solution to the above diazonium salt, and carry out acidic coupling at 5-8°C. After the reaction is completed, add the diazonium salt of 6-sulfate hydroxyethylsulfonyl-2-naphthylamine-1-sulfonic acid (compound 14) dropwise to the above-mentioned acidic coupling monoazo dye reaction solution, and maintain 10°C and pH 6~6.5 Respond to the end point. The navy blue component dye 105 was obtained after membrane separation to remove salt and spray drying.

Embodiment 2

[0081] Add 15g sodium hydroxymethanesulfonate to 10% J acid solution (0.1mol), and react at below 50°C for 4h to obtain 2-sulfomethylamino-5-naphthol-7-sulfonic acid solution. Add 0.1mol para-ester diazonium salt solution to the above coupling components, control the pH ≤ 2, and couple at 0-5°C until the reaction is complete; adjust the pH to 5-6 and then add 0.1mol 2-methoxy-4- The diazonium salt of sulfate ethyl sulfone aniline is added dropwise to the monoazo dye, and the pH is controlled at 6-6.5. After the secondary coupling reaction is completed, desalination and spray drying are performed to obtain reddish-brown powdery red component dye 302.

Embodiment 3

[0083] Add 0.5 part of methylnaphthalenesulfonic acid formaldehyde condensates as dispersant in 0.1mol anthranilic acid diazonium salt solution, after stirring, join the 3,5-diaminobenzoic acid sodium (0.1mol ), a coupling was performed at 5°C. Control the pH of the reaction solution to ≤3 until the primary coupling is complete. Add 0.2 mol para-ester diazonium salt solution dropwise to the primary coupling solution, and gradually increase the pH to 6-6.2 at room temperature until the reaction is complete. Salt out, dry and pulverize to obtain the brown-yellow-brown yellow component dye 501.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com