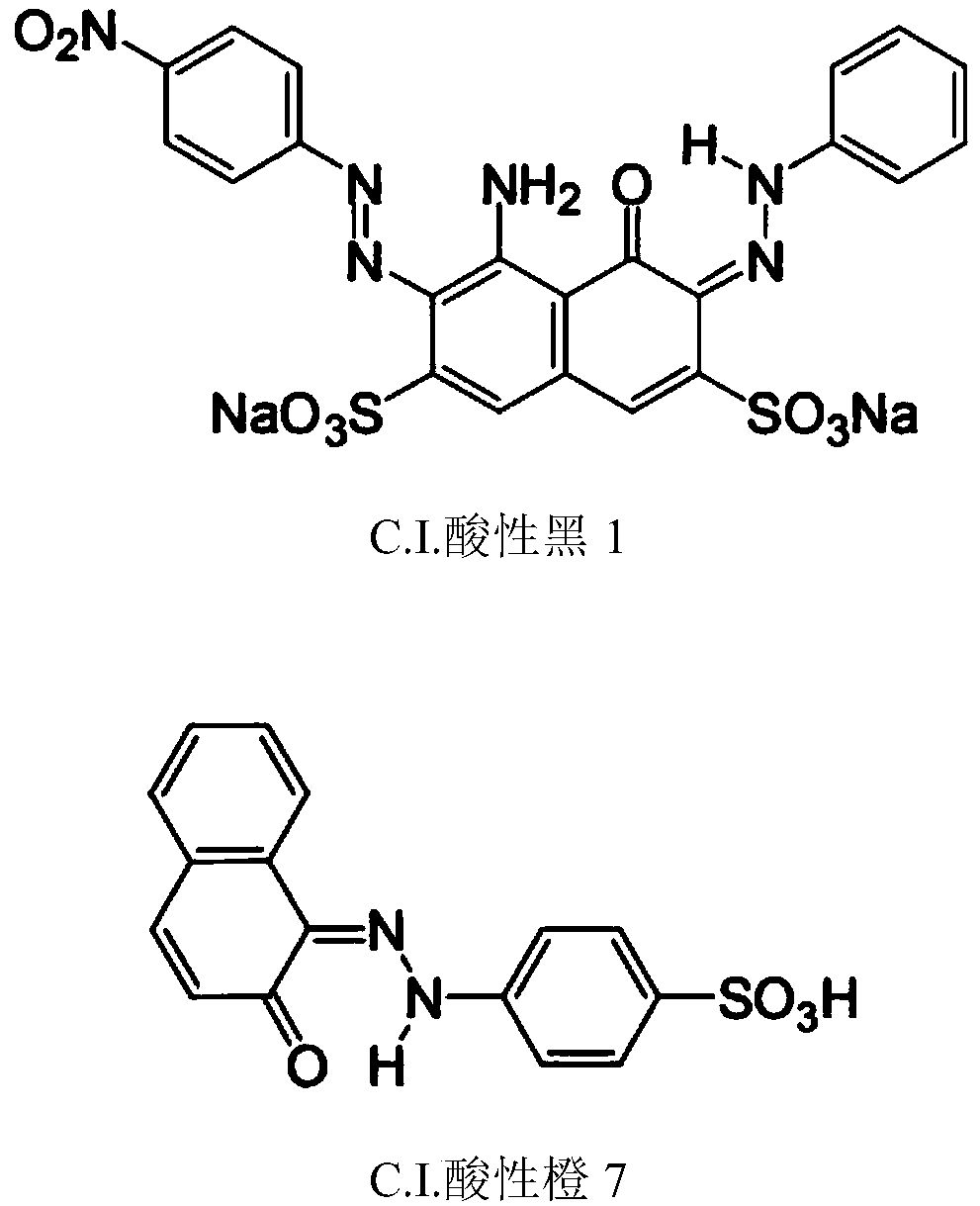

Highly sun-proof type acid black dye composition

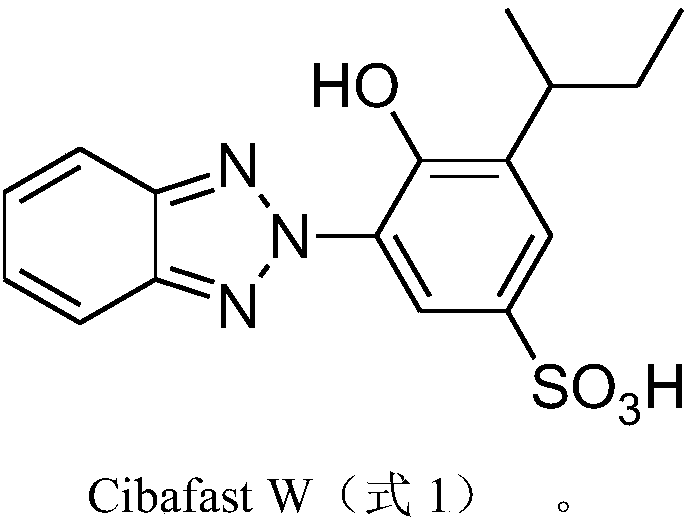

A dye composition, acid black technology, applied in the directions of organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of affecting the service life of textiles, discoloration, fading and discoloration of dyed fibers, etc., and achieve good dyeing rate and light fastness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

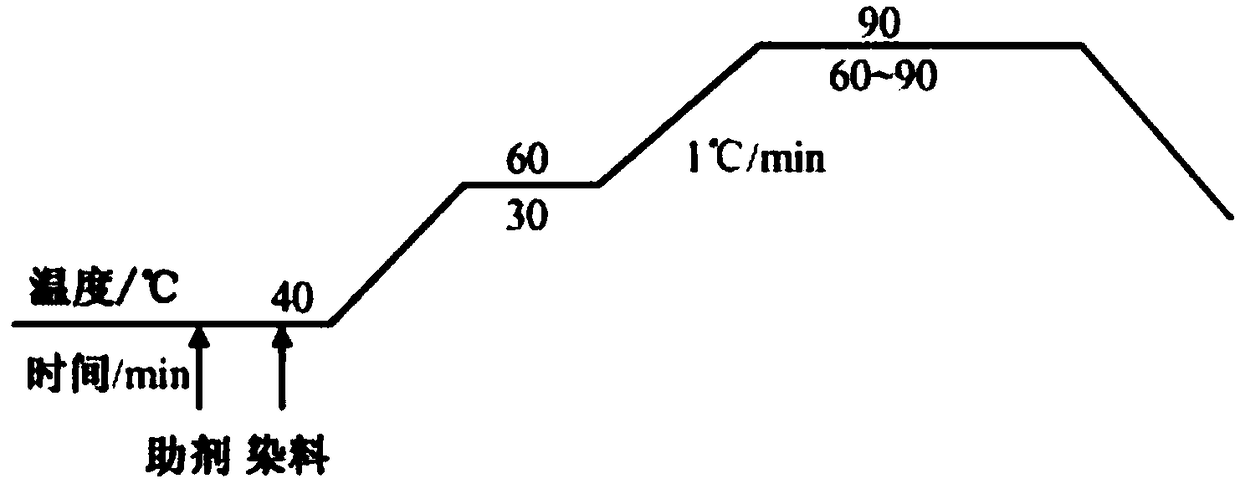

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below in conjunction with specific embodiment, but protection scope of the present invention is not limited thereto:

[0031] The preparation method of the compound described in embodiment 1, formula 3, carries out the following steps successively:

[0032] 1), in the o-nitroaniline (I) of 0.03mol, add the concentrated hydrochloric acid (the hydrochloric acid that mass concentration is 36%) and 30ml water of 12ml, above-mentioned reaction solution is joined in the reactor, after stirring at room temperature 40min, will The temperature of the system is lowered to 0-5°C, and then an aqueous solution of sodium nitrite (sodium nitrite mass concentration is 20%) is added dropwise to the reactor, and the molar ratio of sodium nitrite to the diazo component (that is, o-nitroaniline) is 1.1:1; react for 2hr (at this time, the starch potassium iodide test paper turns blue within 2s, showing excessive sodium nitrite), and finally remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com