Edible porous artificial sausage casing of collagenous fiber and its production process

A collagen fiber, production method technology, applied in sausage casings, food preparation, food science and other directions, can solve the problems of not revealing the unique flavor of sausage, the casing is easy to break, does not have micropores, etc., and achieves good elasticity, not easy to break, The effect of formulation science

Inactive Publication Date: 2002-02-27

苗文忠

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But this kind of casing is easy to break and the cost is high

In order to make the casing not easy to break and reduce the production cost, people invented ordinary collagen casing, but this kind of casing does not have micropores and cannot reveal the unique flavor of sausage

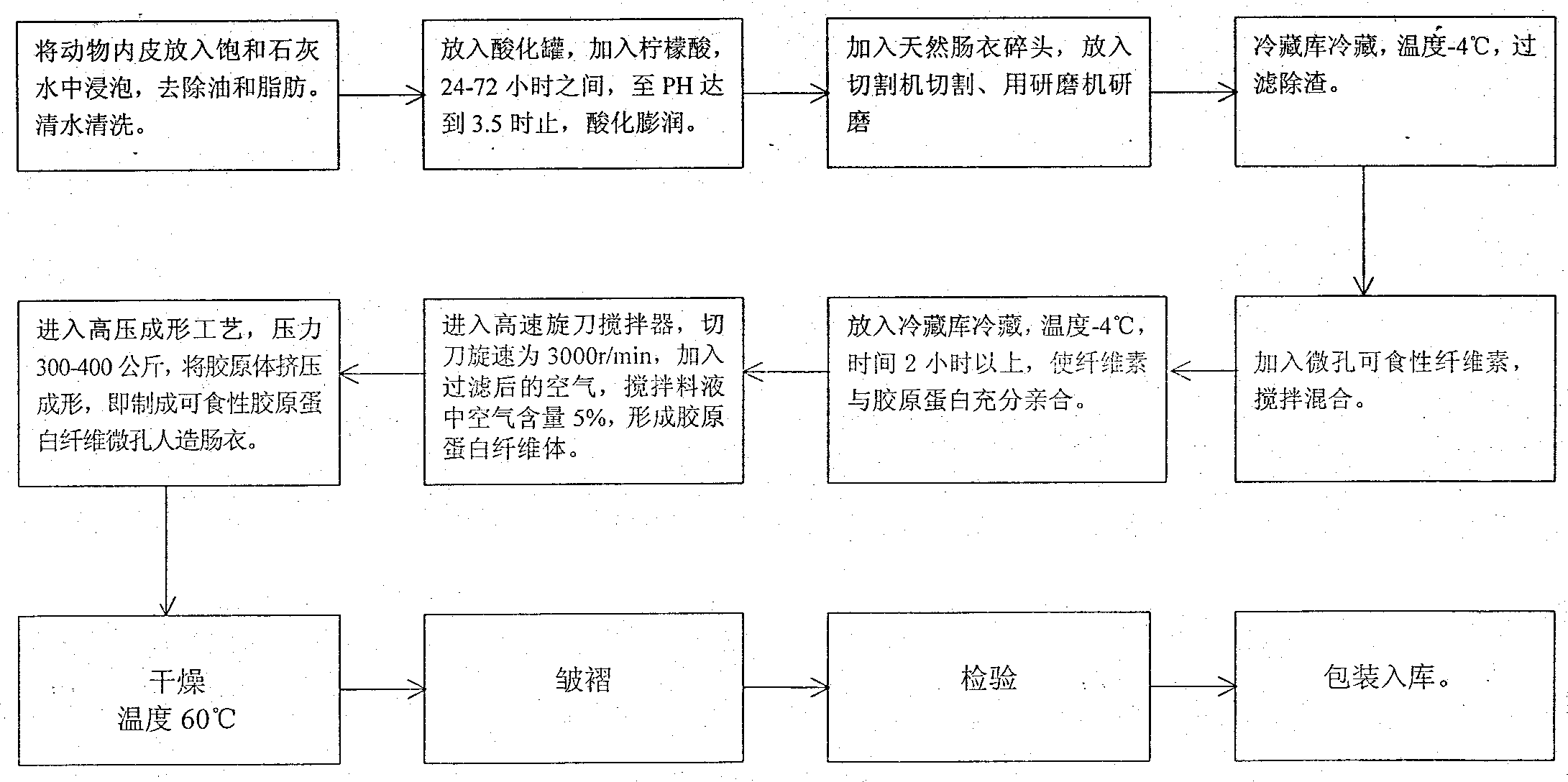

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] The embodiment of production raw material weight part of the present invention is: animal endothelium 100kg, microporous edible cellulose 5kg, natural sausage casing broken head 20kg, saturated lime water 150kg, citric acid 15kg.

[0010] The production method of the present embodiment is the same as above.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an edible collagen protein fibre microporous artificial sausage skin and its production method. It is characterized by that its raw material contains internal skin ofanimal, microporous edible ellulose, scraps of natural sausage skin, saturated lime water and citric acid, and its advantages lie in that its raw material composition is particular, and its operationis simple and scientific, and its permeability is identical to that of natural sausage skin, and its elasticity is good, so it can be substituted for natural sausage skin, and its cost is low.

Description

1. Technical field [0001] The invention relates to an edible collagen fiber microporous artificial casing and a production method thereof, in particular to an edible collagen fiber microporous artificial casing and a production method thereof. 2. Background technology [0002] At present, because the natural casing itself has micropores, it is called natural molecular sieve. During the sausage making process, the casing has micropores that can gradually seep out the moisture in the meat, forming the unique flavor of the sausage. But this kind of casing is easy to break, and the cost is higher. In order to make the casing unbreakable and reduce the production cost, people invented the common collagen casing, but this casing does not have micropores and cannot reveal the unique flavor of the sausage. 3. Contents of the invention [0003] The object of the present invention can be achieved through the following embodiments: the production raw materials of the present invent...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A22C13/00A23L13/20

Inventor 苗文忠

Owner 苗文忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com