Edible collagen casing and production method thereof

A collagen and edibility technology, applied in sausage casings, food preparation, food science, etc., can solve the problems of not revealing the unique flavor of sausages, limited resources of natural casings, and no micropores, etc., to achieve good elasticity, convenient operation, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

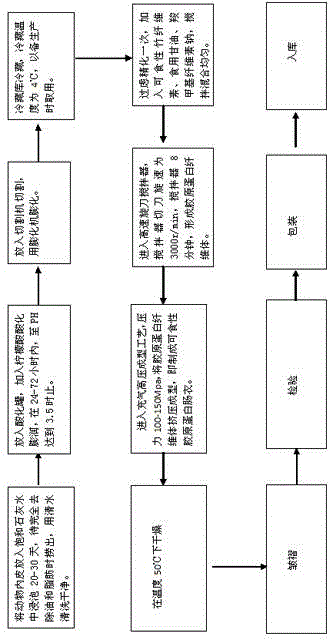

Method used

Image

Examples

Embodiment 1

[0036] Animal endothelium 90kg, edible bamboo cellulose 4.5kg, edible glycerin 4.5kg, sodium carboxymethylcellulose 0.27kg, saturated lime water 135kg, citric acid 13.5kg.

Embodiment 2

[0038] Animal endothelial 100kg, edible bamboo cellulose 5kg, edible glycerin 5kg, sodium carboxymethyl cellulose 0.3kg, saturated lime water 150kg, citric acid 15kg.

Embodiment 3

[0040] Animal endothelium 110kg, edible bamboo cellulose 5.5kg, edible glycerin 5.5kg, sodium carboxymethylcellulose 0.33kg, saturated lime water 165kg, citric acid 16.5kg.

[0041] If the sausage casing needs to be produced in large quantities by the present invention, the content can be increased according to the above-mentioned raw material formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com