Method of manufacturing low permeation ion exchange membrane

The technology of an ion exchange membrane and a manufacturing method is applied in the field of improvement of the formulation and manufacturing method of a low-permeability ion exchange membrane, which can solve the problems of inability to obtain ultrapure water, feed water, increase energy consumption for post-processing, etc., and achieve product loss. The effect of reducing, long service life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] a. positive film

[0034] Strong acid styrene cationic resin powder 5.5kg High pressure polyethylene 1.8kg

[0035] Polyisobutylene 0.4kg Initiator Benzoyl Peroxide 0.05kg

[0036] Vinyltrimethoxysilane 0.1kg Crosslinking agent divinylbenzene 0.1kg

[0037] Antioxidant pentaerythritol fat 0.005kg high melting point paraffin 0.05kg

[0038] Silicone release agent 0.02kg red pigment 0.005kg

[0039] b: Yin membrane

[0040] Strong basic styrene anion resin powder 5kg High pressure polyethylene 1.2kg

[0041] Polyisobutylene 0.4kg Initiator Benzoyl Peroxide 0.05kg

[0042] Vinyltrimethoxysilane 0.1kg Crosslinking agent divinylbenzene 0.02kg-0.06kg

[0043] Antioxidant pentaerythritol fat 0.005kg high melting point paraffin 0.05kg

[0044] Silicone release agent 0.02kg Blue or green pigment 0.005kg

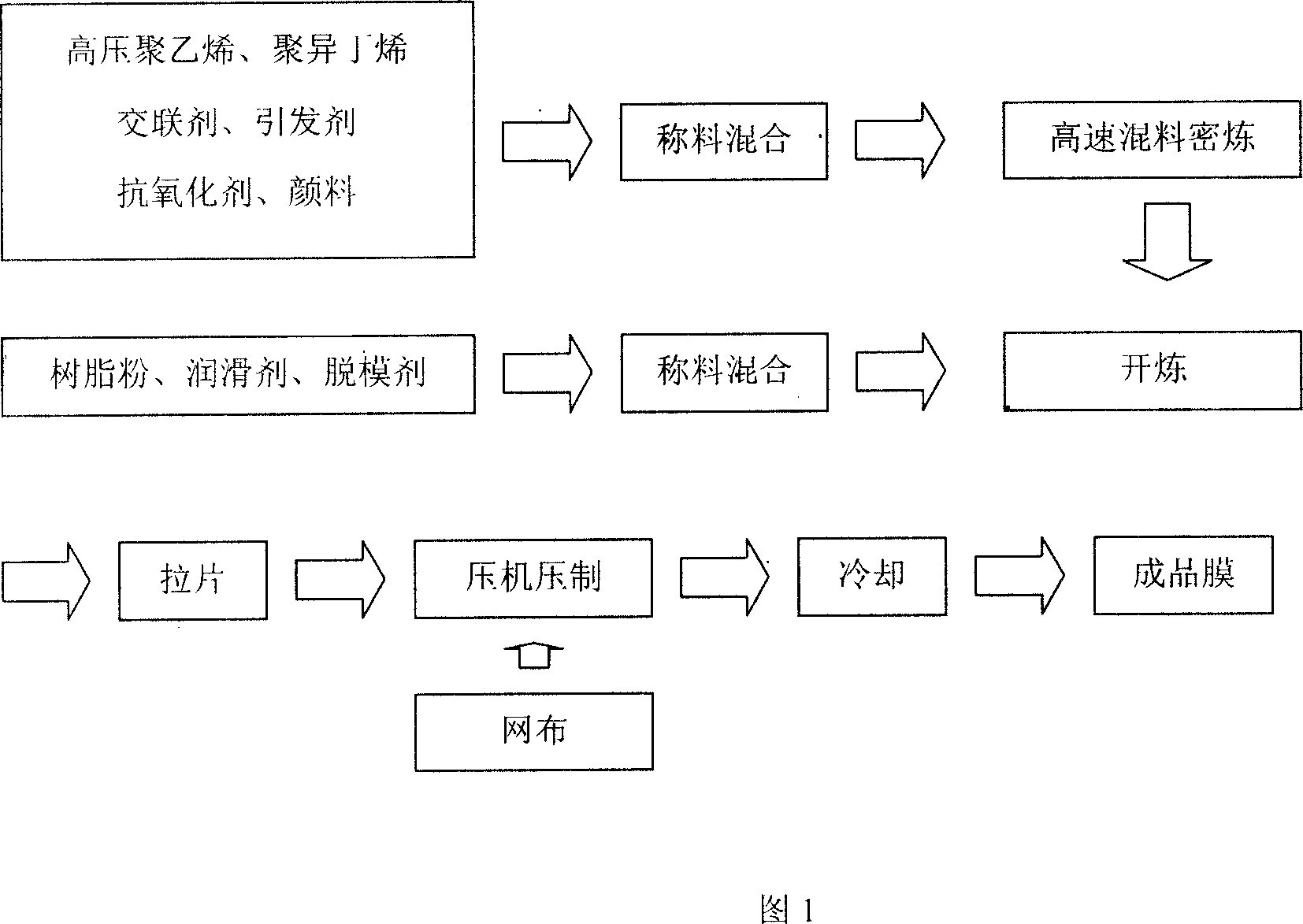

[0045] Send the high-pressure polyethylene, polyethylene butylene, coupling agent, antioxidant, initiator, and pigment into the high-speed mixer in proportion, mix them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com