Recovery method of N-methylmorpholine oxide solvent in process of generating regenerated protein fibre by solvent method

A technology for regenerating protein and methylmorpholine, which is applied in the fields of fiber chemical characteristics, rayon recycling, and final product manufacturing, can solve the problems of NMMO solvent loss, difficulty in industrial promotion, and increased production cost of regenerated protein fibers Effects of burden, life extension, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

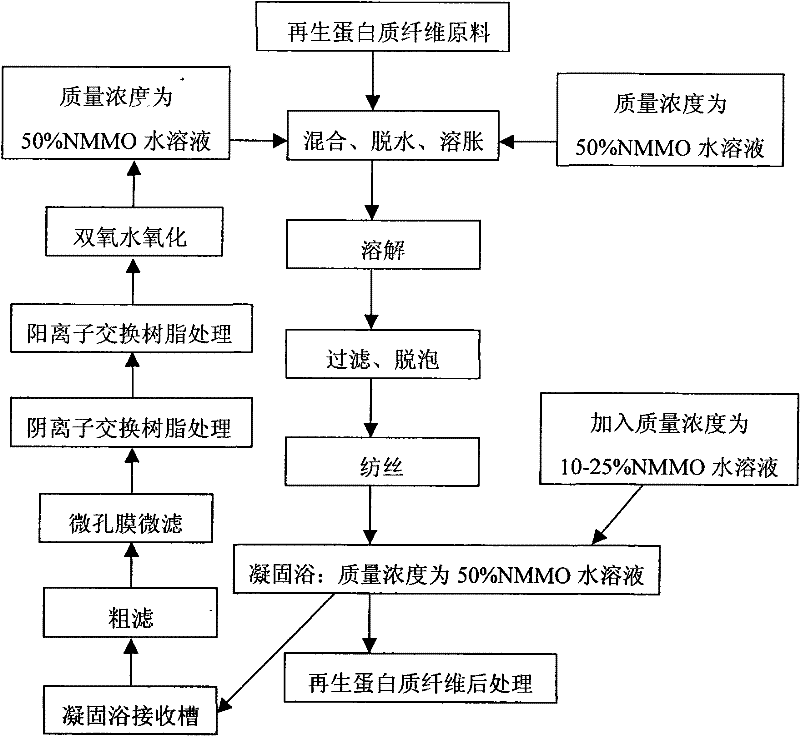

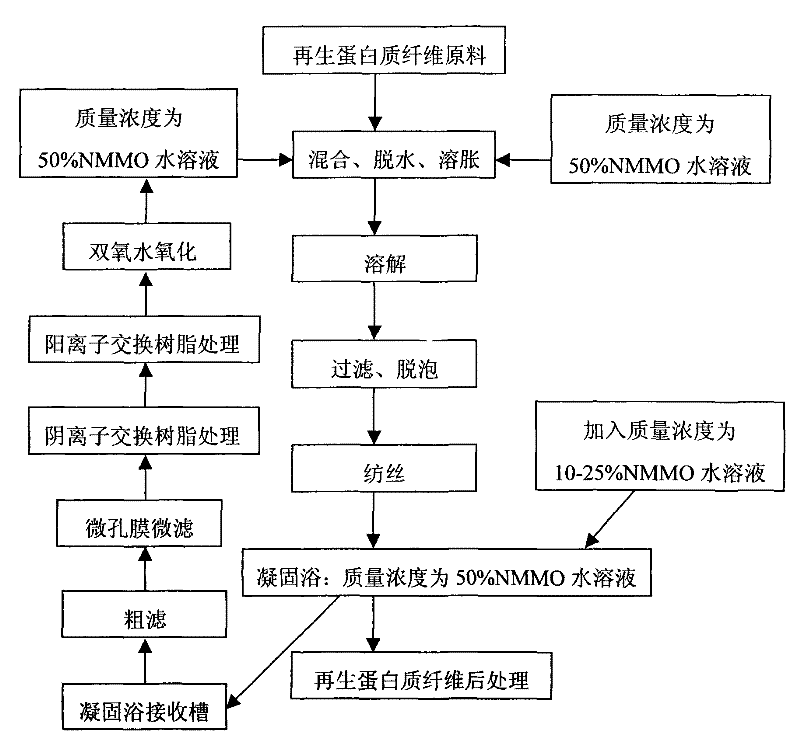

[0029] See figure 1 .

[0030](1) In the spinning process production of the regenerated silk protein fiber prepared by the solvent method, the NMMO aqueous solution with a commercially available mass concentration of 50% is used as a solvent to indirectly dissolve silk fibroin leftovers to prepare the regenerated silk protein fiber; the mass concentration is 50% The NMMO aqueous solution is a coagulation bath for regenerated silk protein fibers;

[0031] (2) Along with the carrying out of spinning process, add the NMMO aqueous solution that mass concentration is 25% in the coagulation bath of step (1) with the flow velocity of 140kg / h, make containing mass concentration be 50% with the flow velocity of 270kg / h simultaneously The NMMO aqueous solution discharges the container of loading coagulation bath in the receiving tank, under making the NMMO aqueous solution coagulation bath effectively circulates, the mass concentration of the NMMO aqueous solution coagulation bath in t...

Embodiment 2

[0038] (1) In the spinning process production of regenerated animal hair fiber prepared by solvent method, the NMMO aqueous solution with a commercially available mass concentration of 50% is used as a solvent to indirectly dissolve wool waste to prepare regenerated animal hair fiber; The NMMO aqueous solution is a coagulation bath for regenerated animal hair fibers;

[0039] (2) Along with the carrying out of spinning process, add the NMMO aqueous solution that mass concentration is 10% in the coagulation bath of step (1) with the flow velocity of 0.44kg / h, make containing mass concentration be with the flow velocity of 1.09kg / h simultaneously 50% NMMO aqueous solution discharges the container of loading coagulation bath to receiving tank, under making NMMO aqueous solution coagulation bath effectively circulates, the mass concentration of the NMMO aqueous solution coagulation bath in loading coagulation bath container is controlled at 50%, obtains in receiving tank Containin...

Embodiment 3

[0046] (1) In the spinning process production of the regenerated animal hair fiber prepared by the solvent method, the NMMO aqueous solution with a commercially available mass concentration of 50% is used as a solvent to indirectly dissolve worn-out animal hair clothes to prepare the regenerated animal hair fiber; with a mass concentration of 50% % NMMO aqueous solution is a coagulation bath for regenerated animal hair fibers;

[0047] (2) Along with the carrying out of spinning process, add the NMMO aqueous solution that mass concentration is 18% in the coagulation bath of step (1) with the flow velocity of 84.375kg / h, make containing mass concentration be with the flow velocity of 184.375kg / h simultaneously 50% NMMO aqueous solution discharges the container of loading coagulation bath to receiving tank, under making NMMO aqueous solution coagulation bath effectively circulates, the mass concentration of the NMMO aqueous solution coagulation bath in loading coagulation bath co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com