Protein fiber/jute fiber blended fabric and production process thereof

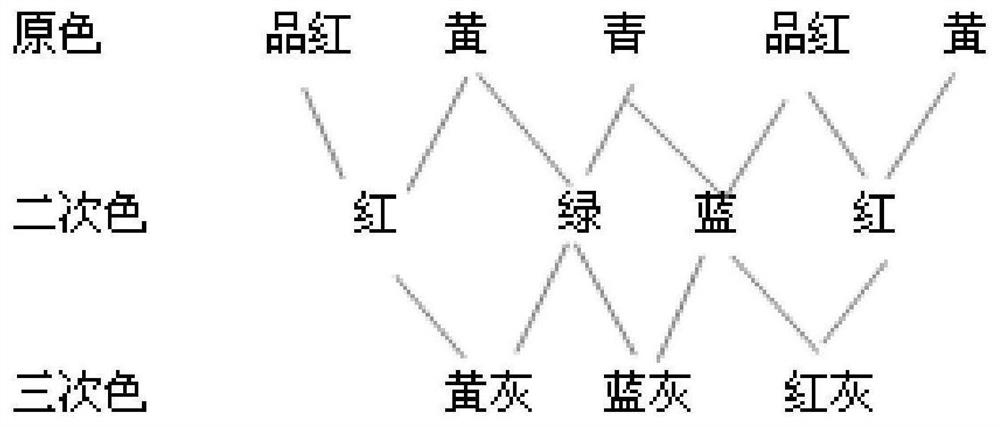

A protein fiber, blended fabric technology, applied in fiber treatment, biochemical fiber treatment, enzyme/microorganism biochemical treatment, etc. Problems such as difficulty in high-count yarns, to achieve the effect of improving the soft and hazy effect of color and light, fluffy between fibers, and reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

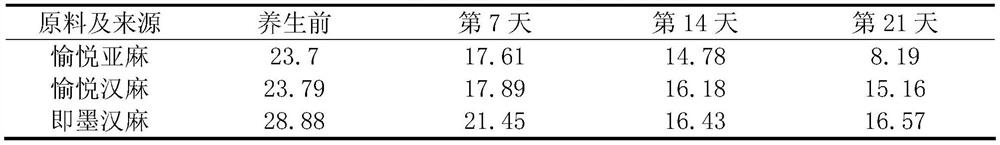

Embodiment 1

[0047] A protein fiber / hemp fiber blended fabric, the fabric is made of protein fibers after pretreatment, neutralization and cleaning, kneading, combing, and drawing. The hemp slivers obtained afterward are drawn, then combed, drawn, roving, spun, dyed and finished to prepare the obtained protein fiber / hemp fiber blended dyed yarn, and then the obtained protein fiber / hemp fiber blended dyed yarn , and then through weaving, the gray cloth is obtained, and then the gray cloth is prepared after finishing, and the weight of the fabric is 200-220g / m 2 , in the present embodiment, the protein fiber is wool fiber; the hemp fiber is hemp fiber. Among them, the gray cloth is obtained by weaving 60 protein fiber / hemp fiber blended dyed yarns as the weft yarn, 1 low melting point network yarn, and 180- 200g / m 2 . The fineness of protein fibers is 15 μm. The length of the hemp fiber is 65mm, the fineness of the hemp fiber is 1800-2800m / g, and the splitting degree is 3000.

[0048] I...

Embodiment 2

[0081] A protein fiber / hemp fiber blended fabric, the fabric is made of protein fibers after pretreatment, neutralization and cleaning, kneading, combing, and drawing. The hemp slivers obtained afterward are drawn, then combed, drawn, roving, spun, dyed and finished to prepare the obtained protein fiber / hemp fiber blended dyed yarn, and then the obtained protein fiber / hemp fiber blended dyed yarn , and then through weaving, the gray cloth is obtained, and then the gray cloth is prepared after finishing, and the weight of the fabric is 250-350g / m 2 , in the present embodiment the protein fiber is a rabbit hair fiber; the hemp fiber is a hemp fiber. Among them, the gray cloth is obtained by weaving 68 protein fiber / hemp fiber blended dyed yarns for the weft yarn, 1 low melting point network yarn, and the low melting point network yarn or protein fiber / hemp fiber blended dyed yarn for the warp yarn, and the gray cloth has a grammage of 200- 300g / m 2 . The fineness of protein f...

Embodiment 3

[0107] A protein fiber / hemp fiber blended fabric, the fabric is made of protein fibers after pretreatment, neutralization and cleaning, kneading, combing, and drawing. The hemp slivers obtained afterward are drawn, then combed, drawn, roving, spun, dyed and finished to prepare the obtained protein fiber / hemp fiber blended dyed yarn, and then the obtained protein fiber / hemp fiber blended dyed yarn , and then weaved to obtain gray cloth, and then prepared by finishing the gray cloth, the weight of the fabric is 180-400g / m 2 , In the present embodiment, the protein fiber is cashmere; the hemp fiber is flax fiber. Among them, the gray cloth is obtained by weaving 72 protein fiber / hemp fiber blended dyed yarns for the weft yarn, 1 low melting point network yarn, and the low melting point network yarn or protein fiber / hemp fiber blended color yarn for the warp yarn, and the obtained gray cloth has a grammage of 145 -300g / m 2 .

[0108] In this embodiment, cashmere blue is used wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com