Collagen fabric casing for sausage knitting and former device

A technology of collagen fibers and formers, applied in sausage casings, slaughtering, food science, etc., can solve problems such as difficulty in chewing and palatability, strength reduction, casing wall thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

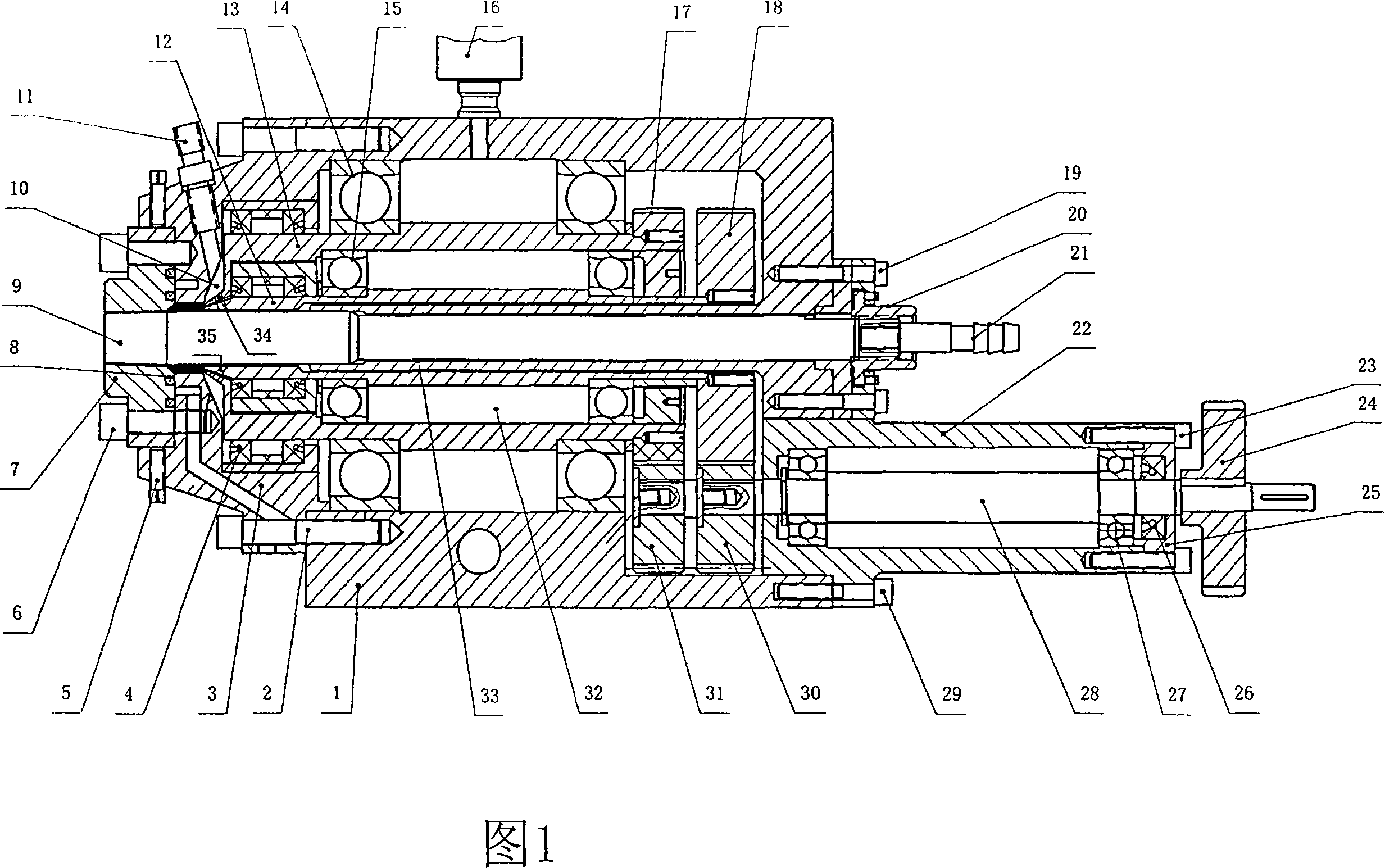

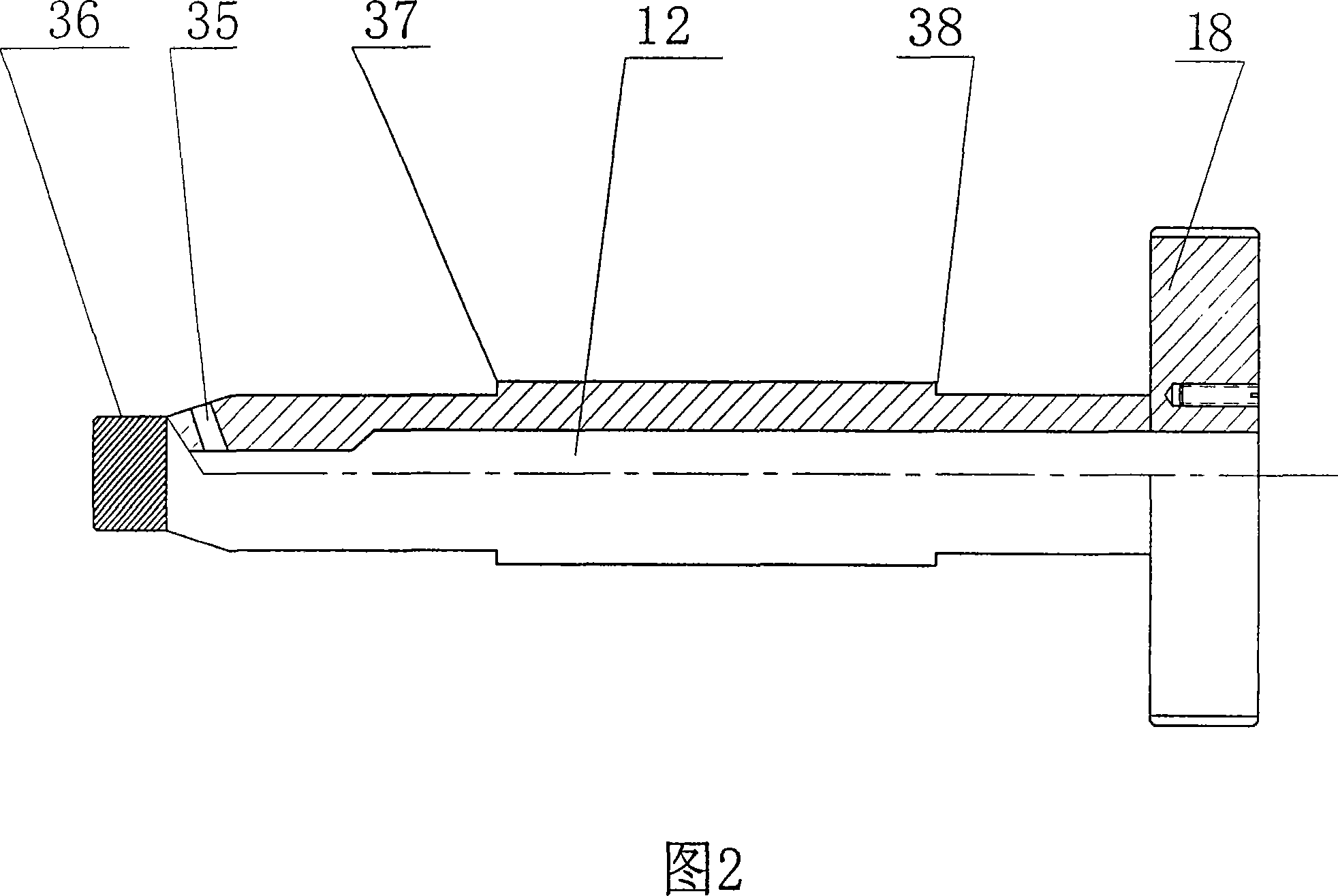

[0018] As shown in Fig. 1, it is a schematic cross-sectional view of the structure of the present invention. As can be seen from the figure, the left end of the machine base 1 is also called discharge or front end, that is, the left end of the machine base 1 is the front end of the former, the same below. A storage bin flange 3 is fixedly connected to the left end surface of the machine base 1 through a screw 2 . On the left end face of the silo flange 3, the annular nozzle 7 of the forming mandrel is fixedly connected with the screw 6, and a sealing ring 8 and an adjusting screw 5 are arranged between the two for adjusting the extruded casing. symmetrical uniformity. In the shaft sleeve 33 at the center of the inner hall 32 of the machine base 1, a tubular forming mandrel 9 penetrating the machine base 1 is arranged. The rear end of the molding mandrel 9 is sealed and communicated with the air inlet nozzle 21, and gas can be blown in. The air inlet nozzle 21 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com