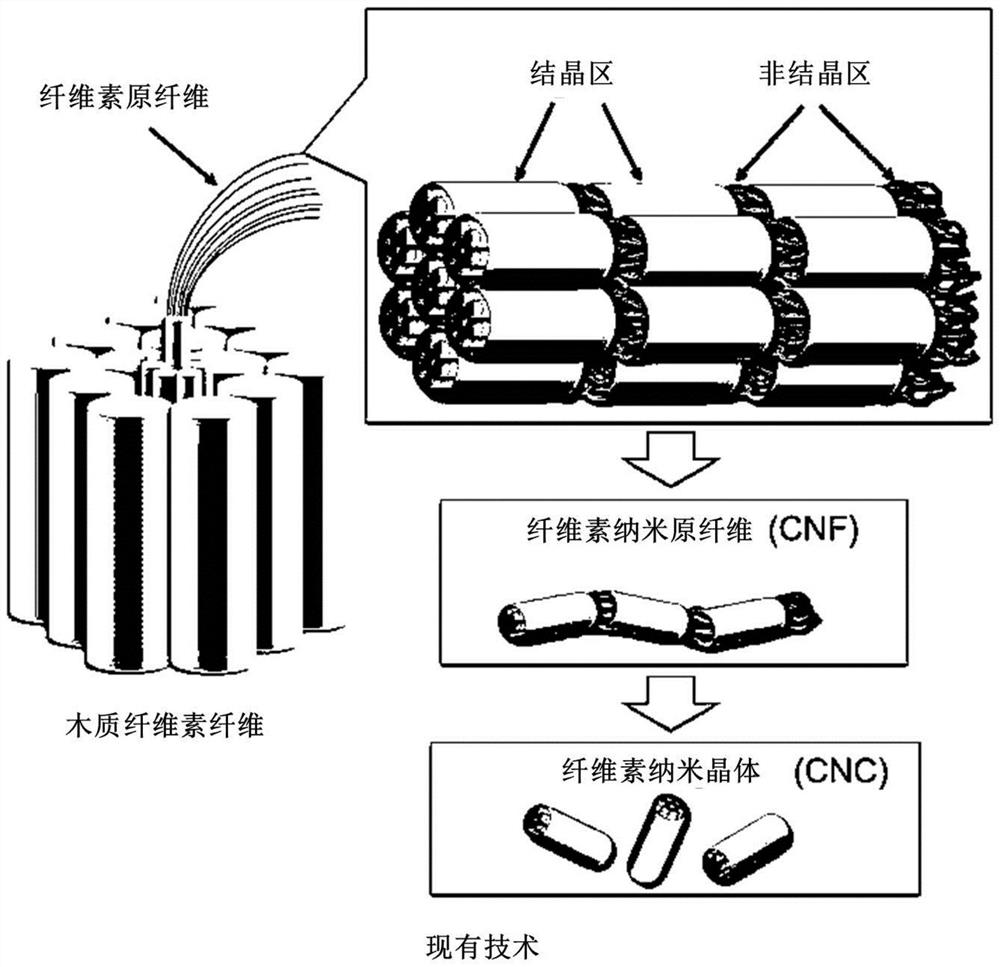

Microparticles comprising cellulose nanocrystals aggregated with proteins and cosmetic use thereof

A technology of nanocrystals and protein aggregation, applied in cosmetics, cosmetic preparations, medical preparations containing active ingredients, etc., can solve problems such as high degradation rate and poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0266] Example 1-7 - Fibroin / cellulose microparticles

[0267] Preparation of Fibroin Solution #1

[0268] Add 1-2g silk fibroin (from Ikeda Corporation - cosmetic grade silk fibroin powder) to 5.55g CaCl at 80°C 2 , 4.6g ethanol, 7.2g distilled water (CaCl 2 : ethanol : H 2 The molar ratio of O is 1:2:8). (Caution: Ajisawa solvent mixture generates a lot of heat). Press down the silk fibroin so that it is completely immersed in the solvent. After 20-30 minutes, the fibroin appears to be completely dissolved and the solution becomes clear and yellow in color.

[0269] The fibroin solution was pipetted into cellulose dialysis tubing and dialyzed against distilled water in a 3.5 L glass beaker. Change the water every hour for the first day, then every half day thereafter. The entire dialysis process took three days.

[0270] After dialysis, the fibroin concentration of the solution in the dialysis tubing is 1.5-2.0% by weight.

[0271] Use fibroin obtained from other so...

Embodiment 1

[0304] Example 1 - Hydrophobic fibroin / cellulose microparticles derived from carboxylated CNC and silk fibroin

[0305] CNC suspension #1 (2.17 wt% CNC) was mixed with fibroin solution #1 (1.8 wt%) such that the final fibroin content was 2 wt% compared to the CNC content. The mixing of CNC and fibroin solution is carried out under minimum shear force, which ensures efficient agitation of volume size. Stirring was carried out until the solution reached homogeneity within 10 minutes. The suspension was spray dried immediately (Techni Process spray dryer, model SD-1; inlet temperature 190°C, outlet temperature 89-92°C, nozzle pressure 2 bar, pressure difference 180 mm WC). After spray drying, the resulting free-flowing white powder can be washed with alcohols such as ethanol, and then placed in an oven at 80°C for 30 minutes to improve the hydrophobic effect. In the obtained microparticles, the content of silk fibroin was 2% by weight.

[0306] Figure 2A) shows a powder sample...

Embodiment 2

[0308] Example 2 - Hydrophobic fibroin / cellulose microparticles wherein the silk fibroin content ranges from 0.5% to 50% by weight compared to the carboxylated CNC content.

[0309] Hydrophobic microparticles were obtained in the same manner as described in Example 1.

[0310] More specifically, silk fibroin solution (2wt%) was added to CNC suspension #1 (0.5wt%) under vigorous stirring to obtain 5wt%, 10wt%, 20wt% and 50wt% of SF solution. The resulting suspension was spray dried on a Büchi MiniSpray Dryer Type B-191 (inlet temperature 175°C and outlet temperature 100°C, 30% pump speed, 70% aspirator). Some samples were treated with methanol to increase the proportion of beta sheet SF in the beads.

[0311] The powder obtained is hydrophobic.

[0312] Figure 4 shows the SEM image of the microparticles obtained.

[0313] For comparison, Figure 5 shows microparticles obtained by spray drying silk fibroin only (ie without CNC).

[0314] The presence of SF in the form of β-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com