Methanol washing system adopting work quantity exchange and process thereof

A technology of power exchange and purification system, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of consumption and the lack of effective utilization of the rich hydraulic energy of the absorption tower, and achieve obvious energy recovery benefits and influences. Small, the effect of smooth system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

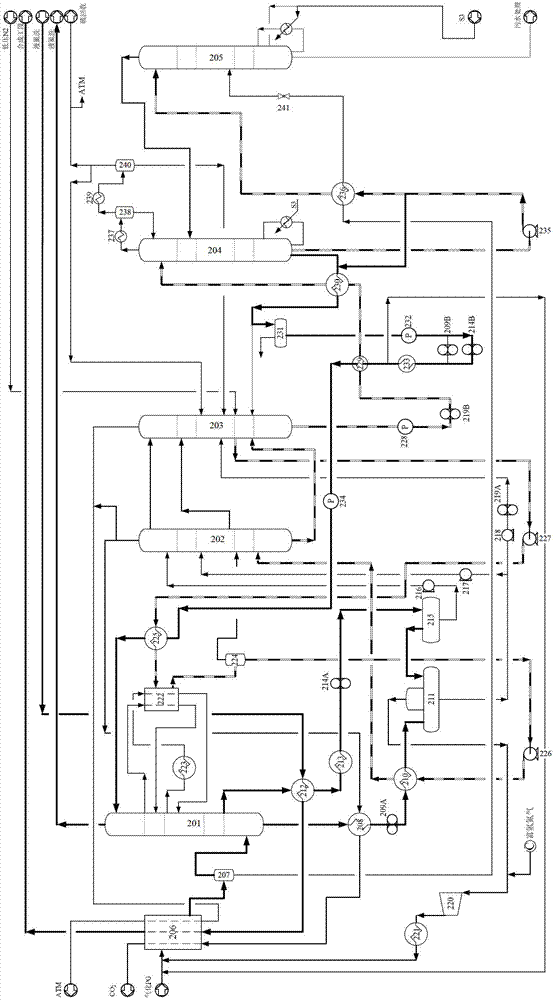

[0032] The present invention will be further described in detail below with reference to the drawings and examples.

[0033] The process of the embodiment of the present invention includes the following processes:

[0034] 1) Syngas pre-cooling

[0035] The crude synthesis gas from the conversion section enters the synthesis gas cooler, and is cooled to -17°C by streams such as the desorption tower top gas phase and the enrichment tower top gas phase.

[0036] 2) Removal of acid gas

[0037] The pre-cooled synthesis gas is in reverse contact with methanol solution, CO 2 , H 2 Acid gases such as S are absorbed, and the syngas is purified.

[0038] 3) Rich hydraulic energy transfer

[0039] The rich liquid obtained by the absorption is exchanged with the two methanol solutions through the positive displacement power exchanger to realize the pressure increase of the methanol solution and the pressure reduction of the rich liquid.

[0040] 4) Flash separation

[0041] The pressure-reduced rich ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com